Powder Bed Fusion (PBF) Processes

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Powder Bed Fusion (PBF)

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we will explore Powder Bed Fusion, or PBF. Can anyone tell me what they believe happens during this process?

I think it involves building parts layer by layer, right?

Exactly! PBF works by spreading a layer of powdered material, then using a heat source to selectively fuse or sinter the particles together. What heat sources do we typically use in PBF?

Is it lasers or maybe electron beams?

Yes! We primarily use lasers or electron beams. Let's remember that with the acronym 'LE' for Laser and Electron. This will help us recall the main heat sources used.

So, after each layer is done, the platform lowers, and we spread more powder?

Correct! This layering continues until the part is fully built. Unfused powder acts as support and is removed later. Can anyone explain why unfused powder is beneficial?

It supports the part during building!

Great job! To summarize, PBF builds parts layer by layer using a heat source to fuse powder together while relying on unfused powder for support.

Materials Used in PBF

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let's talk about the materials used in Powder Bed Fusion processes. Who can name some types of materials we can use?

I think metals and polymers are commonly used!

That's right! Metals like stainless steel and titanium alloys are very common, but we also have polymers like nylon. Can anyone tell me why certain materials are chosen?

Maybe because they have the right properties for the parts we want to make?

Exactly! Properties like strength and thermal stability are key. Let’s remember 'M for Metals and P for Polymers'. What does that help us recall?

Materials used in PBF!

Good! Now, let’s discuss some applications. Why might we choose specific materials for aerospace or medical industries?

They need to be really strong and lightweight!

Absolutely! In summary, PBF utilizes various materials, each selected for their relevant properties and application needs.

PBF Processes Overview

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's look at specific PBF processes. Can anyone name one of the processes we discussed and what materials it uses?

Selective Laser Sintering for polymers!

Exactly! Let's connect this with the acronym 'SLS.' Now, what set of processes use metals?

DMLS and SLM for metals!

Correct! DMLS and SLM focus on melting metals for high precision and density. Why do you think it's important to know the process types?

It helps in selecting the right one for our project?

That's a key point! Different processes yield specific properties and are suited for varied applications. Let's remember 'D for DMLS' and 'S for SLM'.

So, knowing these helps in making better choices!

Perfect! In summary, the understanding of different PBF processes guides proper material selection based on project goals.

Advantages and Limitations of PBF

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let’s break down the advantages and limitations of PBF. Can someone list one advantage?

You can create really complex shapes!

Spot on! High geometric complexity is indeed a major advantage. What about limitations?

The machines are really expensive!

Correct! Cost and operational complexity can be significant considerations. Let's create the acronym 'CL' for Cost and Limitations; thinking of this can help us remember them together. Are there any other limitations we should consider?

Build speeds can be slow, especially for large parts.

Exactly! Slow build speeds and the need for post-processing can significantly affect production timelines. In summary, while PBF has remarkable advantages, understanding its limitations is essential for effective application.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

PBF processes are additive manufacturing techniques that selectively fuse powdered materials using heat sources such as lasers or electron beams. These methods allow for the creation of detailed and mechanically strong parts from metals, polymers, and ceramics, although they come with certain limitations in equipment costs and build speed.

Detailed

Powder Bed Fusion (PBF) Processes

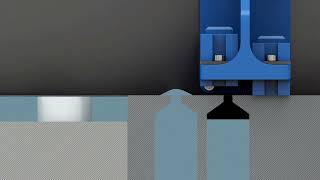

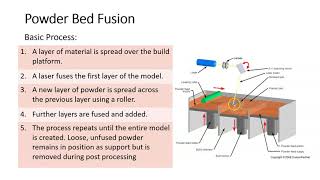

Powder Bed Fusion (PBF) processes are a subset of additive manufacturing that build parts layer by layer by fusing or sintering powdered materials. The process begins with a build platform where a layer of powder is spread uniformly. A heat source—either a laser or an electron beam—fuses the powder particles in a specific pattern corresponding to the desired shape of the part. After processing each layer, the platform is lowered, and fresh powder is applied to form the next layer, repeating this cycle until the final part is complete. Unfused powder remains, providing natural support for the component and is removed during post-processing.

Key Materials in PBF

PBF can utilize a variety of materials:

- Metals: Including stainless steel, titanium alloys, aluminum, cobalt-chrome, and Inconel.

- Polymers: Such as nylon and thermoplastic elastomer composites.

- Ceramics: Emerging applications but less common compared to metals and polymers.

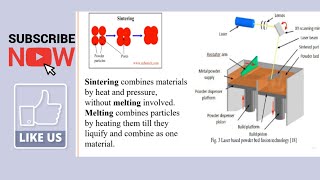

Mechanisms of Powder Fusion

Depending on the heat source and specific technique, different methods of fusion or sintering are employed:

- Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS) focus on full melting for dense metal parts.

- Selective Laser Sintering (SLS) involves partial fusion mainly for polymers.

- Electron Beam Melting (EBM) uses high-energy beams to melt metal powders in vacuum conditions.

Powder Handling in PBF

Proper handling of powders is critical:

- Powders are typically managed in hoppers and applied using rollers or blades to create uniform layers.

- Recycling and reuse of powders are common, but attention must be paid to potential degradation and contamination.

Overview of Common PBF Processes

Different PBF processes utilize distinct heat sources and material types, each with specific applications:

1. Selective Laser Sintering (SLS): Primarily for polymers and prototypes.

2. Direct Metal Laser Sintering (DMLS): Focused on metals for aerospace and medical industries.

3. Electron Beam Melting (EBM): Ideal for titanium and cobalt, used in orthopedics due to reduced residual stress.

4. Directed Energy Deposition (DMD): Useful for large part repair and multi-material capabilities.

5. Liquid Binder Jetting: Combines binder with powder for rapid casting processes.

Advantages and Limitations of PBF

Advantages include:

- Ability to produce complex geometries with minimal tooling.

- Capability to create lightweight, optimized parts.

- Strong mechanical properties when process parameters are controlled.

Limitations involve:

- High equipment costs and complex operations.

- Slower build speeds for larger parts.

- Safety considerations regarding fine metal powders.

- Often requires post-processing for surface finish.

In summary, PBF processes are crucial in modern additive manufacturing, facilitating the journey from design to production of intricate components across various industries, while understanding the distinctions among techniques is essential for optimal application.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Working Principle of PBF

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

PBF techniques build parts layer-by-layer by selectively fusing or sintering powdered material spread uniformly over a build platform.

A heat source (laser or electron beam) fuses powder particles in the desired pattern for each layer.

After one layer is processed, the platform lowers, a fresh powder layer is spread, and the process repeats until the part is complete.

Unfused powder acts as natural support and is removed during post-processing.

Detailed Explanation

Powder Bed Fusion (PBF) is a 3D printing technique that creates objects in layers. It works by spreading a thin layer of powdered material over a platform. A laser or an electron beam is then directed onto this layer to heat up specific areas, causing the powder particles to fuse together at those points. Once this layer is solidified, the platform lowers slightly, allowing another layer of powder to be spread on top. This process continues until the entire object is formed. After printing, any unused powder is cleared away, which can often be reused for future prints.

Examples & Analogies

Imagine making a cake using layers of sponge. First, you bake one layer and set it aside. Then, you add another layer of batter on top of the first one, repeating until your cake is complete. In PBF, instead of batter, you’re using powdered materials, and instead of an oven, you have a laser that melts the powder together.

Materials Used in PBF

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Metals: Stainless steel, titanium alloys, aluminum, cobalt-chrome, Inconel, and others.

Polymers: Nylon, TPU, PA composites.

Ceramics (less common but emerging).

Detailed Explanation

Various materials can be used in Powder Bed Fusion processes. Metals such as stainless steel, titanium alloys, and aluminum are commonly used due to their strength and durability. Polymers like nylon and thermoplastic polyurethane (TPU) are utilized, especially in applications needing flexibility. Additionally, ceramics are starting to emerge as a viable option for certain specialized applications, indicating flexibility in PBF technology.

Examples & Analogies

Think of PBF materials similarly to a chef selecting ingredients for a dish. Just as a chef chooses between meats, vegetables, and spices based on the desired outcome of the meal, engineers choose from metals, polymers, and ceramics to create parts tailored to specific needs, whether that’s strength, flexibility, or heat resistance.

Powder Fusion Mechanism

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Depending on power source and process, powder melting or sintering occurs:

- Selective Laser Melting (SLM)/Direct Metal Laser Sintering (DMLS): Full melting for dense parts.

- Selective Laser Sintering (SLS): Partial fusion/sintering mainly for polymers.

- Electron Beam Melting (EBM): High-energy electron beam melts metal powders in vacuum conditions.

Detailed Explanation

The fusion mechanism of powders in PBF depends on the specific process being used. For example, Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS) involve fully melting the metal powders to create dense parts. Selective Laser Sintering (SLS) is more common for polymers and partially fuses the powders. Meanwhile, Electron Beam Melting (EBM) uses high-energy beams in a vacuum to ensure that metal powders are melted properly, reducing defects and improving the structural integrity of the finished product.

Examples & Analogies

Think of melting chocolate in different ways. You can use a microwave, which completely liquefies it, or let it sit out at room temperature, where it softens but doesn't melt entirely. Similarly, SLM melts metals fully while SLS only partially melts polymers, which also affects the final product’s properties.

Powder Handling in PBF

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Powders are stored in hoppers or feedstocks.

Spreading methods include rollers or blades to achieve consistent, thin layers (typ. 20–100 microns).

Powder recycling and reuse are common, considering powder degradation and contamination.

Detailed Explanation

Handling the powder used in PBF is crucial for successful printing. Powders need to be carefully stored in containers known as hoppers. When applying the powder onto the build platform, methods like rollers or blades are used to ensure that a very thin and even layer is spread, with thickness typically between 20 to 100 microns. This is important for achieving a consistent end product. Often, any powder that is not fused can be recycled for future use, although it is essential to monitor for degradation and contamination that could affect quality.

Examples & Analogies

Imagine making cookies. You need to carefully measure and spread flour so that each batch turns out perfect. You wouldn’t just dump a huge pile of flour – you’d want an even, fine layer to ensure your cookies bake uniformly. In PBF, spreading powder evenly is as essential for successful manufacturing.

Common PBF Processes

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

| Process | Heat Source | Materials | Applications | Comments |

|---|---|---|---|---|

| Selective Laser Sintering (SLS) | Laser | Polymers, composites | Polymer-focused prototypes, tooling | Flexible |

| Direct Metal Laser Sintering (DMLS)/SLM | Laser | Metals, alloys | Aerospace, medical implants | Dense metallic parts |

| Electron Beam Melting (EBM) | Electron beam | Metals (Ti, Co-Cr) | Aerospace, orthopedics | Less residual stress |

| Laser Engineered Net Shaping (LENS) | Laser | Metals, alloys | Part repair, low volume production | Deposition variant, no melting |

| Liquid Binder Jetting + Sintering | Binder + laser | Metals, ceramics | Rapid casting (sand molds) | Wide material range |

| Direct Metal Laser Deposition (DMD) | Laser | Metals | Repair and coating | Multi-material capability |

Detailed Explanation

There are several PBF processes tailored for different applications. For instance, Selective Laser Sintering (SLS) uses lasers to melt polymers for prototypes, while Direct Metal Laser Sintering (DMLS) produces dense metal parts mainly for the aerospace and medical fields. Electron Beam Melting (EBM) is effective for metal with minimal defects due to its vacuum environment. Laser Engineered Net Shaping (LENS) allows parts to be built using layers without complete melting, and Liquid Binder Jetting offers a rapid casting solution using binders and heat for metals and ceramics.

Examples & Analogies

Consider a toolbox containing various tools, each designed for specific tasks. Some tools are more suited for delicate work (like SLS for polymers), while heavier tools can handle tough jobs (like DMLS for dense metals). In PBF, each process serves different industries and requirements, demonstrating the importance of selecting the right 'tool' for the job.

Key Concepts

-

PBF Processes: Utilizing layers of powder fused together by lasers or electron beams.

-

Materials: Metals, polymers, and ceramics can be used, depending on desired properties.

-

Heat Sources: Lasers and electron beams are the primary sources for fusing powder.

-

Process Types: Different processes like SLS, DMLS, and EBM cater to specific applications.

-

Advantages & Limitations: PBF allows complexity in design but involves costs and often slow speeds.

Examples & Applications

Selective Laser Sintering (SLS) is mainly used for creating prototypes in polymer.

Direct Metal Laser Sintering (DMLS) is utilized in producing intricate aerospace components from titanium.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

In layers we stack, let the lasers act, creating complex shapes, no need for a pact.

Stories

Imagine a sculptor using powder as their clay. They layer it, melting it with a beam of light, crafting a masterpiece layer by layer.

Memory Tools

Think of 'PBF' as 'Perfectly Built Forms,' which highlights the purpose of the process.

Acronyms

Use 'L & E' to remember 'Laser & Electron' as the two heat sources in PBF processes.

Flash Cards

Glossary

- Powder Bed Fusion (PBF)

An additive manufacturing process that builds parts layer by layer through the selective fusion of powdered material.

- Selective Laser Sintering (SLS)

A powder bed fusion process that uses a laser to selectively fuse powdered material, primarily for polymers.

- Direct Metal Laser Sintering (DMLS)

A PBF process that fully melts metal particles using a laser to create dense parts.

- Selective Laser Melting (SLM)

A process closely related to DMLS that focuses on fully melting metal powders for high precision.

- Electron Beam Melting (EBM)

A PBF technique that uses an electron beam to melt metal powders in a vacuum environment.

- Powder Recycling

The practice of collecting and reusing unfused powder material to reduce waste in additive manufacturing.

Reference links

Supplementary resources to enhance your learning experience.