Fused Deposition Modeling (FDM) Process and Working Principle

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Fused Deposition Modeling

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today we'll be discussing Fused Deposition Modeling, or FDM for short. FDM is a method of additive manufacturing that creates objects layer by layer using thermoplastic materials. Can anyone tell me what thermoplastics are?

Aren't thermoplastics materials that become soft when heated?

Exactly! And when cool, they solidify. FDM melts a filament of thermoplastic and builds an object by depositing it layer by layer. Why do you think layer-by-layer construction is effective?

Because it allows for complex shapes to be made that would be hard to create with traditional manufacturing.

Great point! This flexibility is one of FDM's key advantages. Now, let's remember that FDM printers operate in three axes: X, Y, and Z which allows for this complex geometry. Can anyone remember another aspect we should keep in mind about FDM printers?

They use G-code from CAD systems to guide the printing process.

Correct! G-code is the language that defines how the printer moves while it builds the object. Now let's summarize: FDM is cost-effective and versatile, allowing for a variety of applications.

Materials and Applications of FDM

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's dive deeper into the materials used in the FDM process. Common thermoplastics include ABS and PLA. Can anyone tell me what they know about these materials?

PLA is biodegradable, right? And ABS is stronger but not biodegradable.

That's correct! ABS is often used for more durable parts while PLA is great for prototypes due to its eco-friendliness. What applications can you think of for these materials?

Prototyping for PLA and functional parts for ABS!

Exactly! FDM is used in various fields such as automotive, aerospace, and even medical devices. Now, can anyone tell me the advantages and limitations of using FDM?

It's cost-effective and versatile, but has lower resolution compared to other methods.

Well summarized! Let's remember that while FDM has benefits, its limitations regarding strength and resolution are important to recognize.

Equipment and Specifications in FDM

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s focus on the equipment used in FDM. FDM printers vary from desk-scale to industrial machines. What do you think is a key feature of these printers?

They have heated nozzles to melt the filament.

Exactly! Without the heated nozzle, we can't extrude the thermoplastic. What do you think is the significance of layer thickness in FDM?

Thicker layers can print faster, but may not be as detailed.

Good observation! Layer thickness typically ranges from 50 to 300 microns, which highly influences the quality of the final product. Can anyone think of how the build volume might affect production?

A larger build volume allows for bigger parts or multiple parts at once.

That's right! Being able to create larger components or several smaller ones can significantly enhance efficiency in production.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

FDM is a widely used additive manufacturing technique that draws thermoplastic filament from a spool, melts it in a heated nozzle, and deposits it onto a build platform in layers, following a design specified by G-code. The process involves moving the print head across three axes and utilizes various thermoplastics including ABS and PLA for product applications in diverse industries.

Detailed

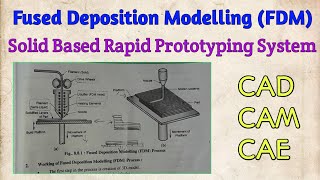

Fused Deposition Modeling (FDM) Process and Working Principle

Fused Deposition Modeling (FDM) is a prominent additive manufacturing process where thermoplastic filaments are heated to a molten state and deposited on a build platform in precise layers. The process involves feeding filament from a spool into a heated extrusion nozzle, which melts the filament before deposition. The nozzle follows a path defined by G-code, typically generated from a CAD model, ensuring accuracy in adhering to specified designs.

The cooled extruded material bonds to the previous layers, constructing the desired 3D components through a layer-by-layer approach. The print head operates in the X, Y, and Z axes, enabling the creation of intricate geometries.

Materials Used

Common thermoplastics include:

- ABS (Acrylonitrile Butadiene Styrene)

- PLA (Polylactic Acid)

- PETG (Polyethylene Terephthalate Glycol)

- Nylon

- TPU (Thermoplastic Polyurethane)

- PEI (Polyetherimide)

Enhanced composites like carbon-fiber reinforced or graphene-doped PLA are also available. Modified systems can even use metals and ceramics in filament or wire form.

Equipment and Specifications

FDM printers range from desktop models to industrial machines, with layer thickness typically varying from 50 to 300 microns. The build size varies significantly, with high-end models capable of producing parts over a meter in any dimension.

Advantages

- Cost-effectiveness and wide accessibility.

- Versatility in material usage.

Limitations

- Lower resolution and surface finish in comparison to alternative AM processes.

- Anisotropic mechanical properties may affect performance, and material strength is often limited.

Applications

FDM is broadly applicable in prototyping, tooling, and manufacturing functional components across various sectors such as automotive, aerospace, medical, and consumer products.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Overview of Fused Deposition Modeling (FDM)

Chapter 1 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

FDM is a material extrusion process where a thermoplastic filament is fed from a spool into a heated extrusion nozzle. The nozzle melts the filament and deposits it layer by layer onto a build platform following a prescribed path from CAD-generated G-code.

Detailed Explanation

Fused Deposition Modeling, commonly known as FDM, is a popular 3D printing technique. The process begins with a thermoplastic filament, which is a type of plastic that becomes soft and pliable when heated. This filament is pulled from a spool into a nozzle that has been heated to the filament's melting point. As the filament is extruded through this nozzle, it is melted and deposited onto a flat surface known as the build platform. The nozzle moves according to a set path designed in computer-aided design (CAD) software, which converts this design into a language the printer understands, called G-code. Layer by layer, the melted filament cools and solidifies, bonding with the previous layers to create a complete 3D object.

Examples & Analogies

Think of FDM like a cake decorator using a piping bag. Just as the decorator squeezes frosting onto the cake in layers to create shapes and designs, the FDM printer 'pipes' melted plastic in layers to build a three-dimensional object.

Cooling and Solidification Process

Chapter 2 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The extruded material cools and solidifies, fusing with previous layers to form the 3D component. The print head moves in three axes (X, Y, Z) to build complex geometries.

Detailed Explanation

Once the melted filament is deposited, it immediately begins to cool down. As it cools, it solidifies and adheres to the layer beneath it. This process is crucial as it allows the creation of intricate shapes and detailed designs. The printer's print head moves along three primary axes—X (left to right), Y (forward and backward), and Z (up and down)—allowing the machine to craft objects with complex geometries and different heights. This three-dimensional movement is key to achieving the desired shape of the final product.

Examples & Analogies

Imagine building a sandcastle by layering sand. You start by putting down a base layer and then add more sand on top. After each layer, the sand firms up as it dries, allowing you to continue adding more and create towers and walls. Similarly, FDM builds up an object layer by layer, allowing for detailed designs that wouldn't be possible if everything were built at once.

Common Materials Used in FDM

Chapter 3 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Typical thermoplastics: ABS, PLA, PETG, Nylon, TPU, PEI. Composite or enhanced filaments: carbon-fiber reinforced, graphene-doped PLA. Some metals and ceramics are also available in filament or wire forms for modified FDM equipment.

Detailed Explanation

FDM printers primarily use thermoplastic materials, which are chosen based on their properties and the requirements of the object being printed. Common thermoplastics include ABS (Acrylonitrile Butadiene Styrene), which is known for its strength; PLA (Polylactic Acid), which is biodegradable and easy to print; PETG (Polyethylene Terephthalate Glycol), which balances strength and flexibility; Nylon for its durability; TPU (Thermoplastic Polyurethane) for flexibility; and PEI (Polyetherimide) for high-performance applications. Additionally, there are composite filaments, such as carbon-fiber reinforced or graphene-doped PLA, which enhance the mechanical properties of prints. Specialized FDM systems can even print with metals and ceramics, expanding the range of applications significantly.

Examples & Analogies

Choosing the right material for an FDM print is like selecting the right ingredient for a recipe. Just as you would choose flour for baking bread, or chocolate for a cake, you select materials based on the strength, flexibility, and other properties needed for the final product. Each material interacts differently when subjected to heat and cooling in the printing process.

Equipment and Specifications

Chapter 4 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Printer types vary from desk-scale to industrial machines. Layer thickness typically ranges from 50 to 300 microns. Build volume depends on machine size; high-end machines can print parts measuring over a meter in any dimension.

Detailed Explanation

FDM printers come in various sizes and capabilities. Smaller, desk-scale printers are ideal for hobbyists and small projects, while industrial machines are designed for large-scale production and can handle much larger prints. The thickness of each layer, known as layer height, can vary between 50 to 300 microns (1 micron is one-thousandth of a millimeter). This setting affects the detail and smoothness of the final object; thinner layers (e.g., 50 microns) produce finer details but take longer to print, while thicker layers (e.g., 300 microns) speed up the process but may compromise surface finish. The overall build volume is essentially the size of the object the printer can create, with high-end machines offering dimensions greater than one meter.

Examples & Analogies

Think of printers like construction tools. Just as a small hammer can work for home repairs, but a large construction crane is needed for building skyscrapers, FDM printers are designed based on the scale of the projects they are meant to undertake. The layer height in printing is similar to the thickness of layers in a cake; a cake with very thin layers may look more detailed and elegant, while a dense cake might not have as much intricate detail but is faster to prepare.

Advantages and Limitations of FDM

Chapter 5 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Advantages: Cost-effective, widely accessible, versatile. Limitations: Lower resolution and surface finish relative to other processes, anisotropic mechanical properties, and limited material strength.

Detailed Explanation

FDM has several advantages that make it popular in various settings. Primarily, it is cost-effective and accessible, with many affordable models available for home and educational use. Its versatility allows for a wide range of applications, from prototyping to production of functional parts. However, FDM does have limitations. The resolution, which refers to how fine the detail of the print is, tends to be lower compared to other 3D printing processes, and the surface finish might not be as smooth. Additionally, the anisotropic nature refers to the different mechanical properties in different directions of the printed object, which means that while it may be strong in one direction, it may not be as strong in another. Lastly, the strength of materials available for FDM printing can be limiting in certain applications.

Examples & Analogies

You can compare FDM to a budget-friendly restaurant. It offers great meals at reasonable prices (advantages), but might not provide the finest dining experience or the most exquisite flavors (limitations) compared to a high-end gourmet restaurant. Just as a diner might choose a quicker, cheaper meal for convenience, many 3D printing enthusiasts opt for FDM for its affordability and ease of use, even if some detail may be sacrificed.

Applications of FDM

Chapter 6 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Prototyping, tooling, functional parts for automotive, aerospace, medical, and consumer products.

Detailed Explanation

FDM is widely used across various industries for multiple applications. It is particularly favored for prototyping, where designers create a physical model of their product to evaluate its design before mass production. Tooling refers to creating tools that can be used in manufacturing processes. Additionally, FDM can produce functional parts, which are used directly in vehicles for automotive applications, in parts for the aerospace industry, in medical devices, and in everyday consumer products. Its ability to create complex shapes with relative ease makes it ideal for a range of practical applications.

Examples & Analogies

Think of an architect using a model to showcase a new building design. The prototype helps visualize the final product, and potential adjustments can be made before the actual construction begins. Similarly, companies use FDM to create prototypes of their products, enabling them to test functionality and design before producing them in larger quantities.

Key Concepts

-

Material Extrusion: The process by which melted thermoplastic is deposited layer by layer.

-

CAD-generated G-code: The programming used to control the movement of the print head.

-

Thermoplastics: Various materials used in FDM models, each with unique characteristics.

-

Build Volume: The size of the printable area which impacts the size of objects that can be manufactured.

Examples & Applications

Creating a prototype of a consumer product using PLA for its ease of printing and detail.

Manufacturing a functional part in ABS for automotive applications where strength is critical.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

When layers stack and fill the gaps, FDM is says 'hello' with thermoplastic wraps.

Stories

Imagine a chef layering a cake, each layer representing heated plastic that fuses, creating a 3D treat.

Memory Tools

FDM: Filament, Deposit, Melt. These are the steps of making a print.

Acronyms

G-code

Guide for Creation

Operating Device - Remember this for understanding printer commands.

Flash Cards

Glossary

- Fused Deposition Modeling (FDM)

An additive manufacturing process that builds objects layer by layer by extruding melted thermoplastic material.

- Thermoplastic

A type of plastic material that becomes soft when heated and solidifies upon cooling.

- Gcode

A programming language used to control CNC machines, including FDM printers, that defines movement patterns in the manufacturing process.

- Filament

A long, slender strand of thermoplastic used as the material source for 3D printing in FDM.

- Build Platform

The surface on which the layers of material are deposited during the FDM printing process.

Reference links

Supplementary resources to enhance your learning experience.