Lubricating System in IC Engines

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Functions of Lubricants

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're learning about the functions of lubricants in IC engines. The primary function is to reduce friction, which helps minimize wear between moving parts. Can anyone tell me why this is critical for the engine?

I think if we reduce friction, it helps the engine run smoother and last longer.

Exactly! It also cools moving components by absorbing and transferring heat away. Does anyone know how it achieves this?

It must carry the heat away from the engine parts?

Right! It also cleans components by carrying away debris and protects surfaces from rust. Remember the acronym COOL to help recall these benefits—'Cool, Oil, Out, Lubricates'.

Properties of Effective Lubricants

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's dive into the properties of effective lubricants. Can anyone name one important property?

High viscosity index?

Correct! A high viscosity index allows a lubricant to maintain thickness over various temperatures. What about thermal stability?

Does that mean the lubricant won't break down under high heat?

Great point! Oxidation resistance is also crucial as it prevents sludge formation. To help remember, think of the mnemonic 'V-STO Slide' for Viscosity, Stability, Thermal, Oxidation—key properties to look for.

Methods of Lubrication

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s discuss the methods of lubrication. Who can explain splash lubrication?

It's when parts dip into oil and splash it onto surfaces, right?

That's precisely it! Now compare this with pressure lubrication. What can we say about that?

Pressure lubrication pumps oil under pressure to critical areas.

Exactly! Modern engines commonly use this method for better coverage. Remember the term P-C-S: Pressure, Combined, Splash—different approaches to lubricate.

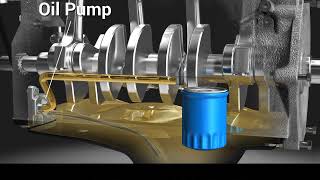

Key Components of the Lubricating System

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s dive into the key components of the lubricating system. What does an oil filter do?

It removes contaminants and helps keep the oil clean?

Great! And how about the oil pump?

It pumps oil under pressure to necessary parts of the engine.

Exactly! Lastly, what about oil coolers?

They cool down the oil to prevent overheating, right?

Correct! They help maintain optimal viscosity. Remember 'FPC' for Filter, Pump, Cooler—key components of the system.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section discusses the various functions of lubricants in IC engines, including reducing friction, cooling components, and protecting surfaces. It further explores the properties of effective lubricants and the different lubrication methods used in engines, along with the key components of the lubricating system.

Detailed

Lubricating System in IC Engines

The lubricating system in internal combustion engines plays a vital role in ensuring the engine operates smoothly and effectively. It serves several key functions:

- Reduce Friction: Lubricants minimize wear between moving parts, enhancing longevity.

- Cool Moving Components: They absorb and transfer heat away from contact areas, preventing overheating.

- Clean Components: Lubricants carry away debris, carbon, and wear particles that could damage engine parts.

- Seal and Protect: They help form seals (like piston rings) and protect surfaces against corrosion and rust.

- Dampen Shocks: Lubricants absorb and cushion abrupt mechanical shocks within the engine, ensuring stability.

Properties of an Effective Lubricant

To be effective, a lubricant must possess several properties:

- High Viscosity Index: Maintains adequate thickness across various temperatures.

- Thermal Stability: Resists breakdown at high temperatures.

- Oxidation Resistance: Minimizes sludge and deposit formation.

- Detergent and Dispersant Qualities: Keeps the engine clean by suspending impurities.

- Low Pour Point: Ensures it remains fluid at low temperatures.

- Non-Corrosive and Non-Foaming: Protects engine metals and prevents aeration.

Methods of Lubrication

There are several methods of lubrication used in IC engines:

1. Splash Lubrication: Common in smaller engines where moving parts dip into oil and splash it onto surfaces.

2. Pressure (Forced Feed) Lubrication: Oil is pumped under pressure to bearings and critical areas, typical in modern engines.

3. Combined System: Utilizes both splash and pressure lubrication for comprehensive coverage.

4. Mist Lubrication: In two-stroke engines, oil mixes with fuel to lubricate as it passes through.

Key Components of the Lubricating System

Essential components include:

- Oil Filters: Remove wear particles, soot, and contaminants, maintaining oil cleanliness.

- Oil Pumps: Deliver oil under pressure to critical areas of the engine. They can be gear, rotor, or plunger types.

- Oil Coolers: Dissipate heat from oil, especially in high-performance engines, maintaining optimal viscosity.

In conclusion, the lubricating system is integral to engine reliability and performance, ensuring that moving parts are protected and operating temperatures are controlled effectively.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Functions of Lubricants

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Functions of Lubricants

- Reduce Friction: Minimize wear between moving parts.

- Cool Moving Components: Absorb and transfer heat away from contact areas.

- Clean Components: Carry away debris, carbon, and wear particles.

- Seal and Protect: Help form seals (e.g., piston rings) and protect surfaces against corrosion and rust.

- Dampen Shocks: Absorb and cushion abrupt mechanical shocks within the engine.

Detailed Explanation

Lubricants serve several essential functions in an internal combustion engine. Most importantly, they reduce friction between moving parts, which minimizes wear and prolongs the engine's lifespan. They also help cool components by absorbing and transferring heat, which protects the engine from overheating. Additionally, lubricants clean the engine by carrying away debris and carbon deposits, ensuring optimal performance. They form seals that prevent oil leaks and protect metals from corrosion and rust. Finally, lubricants dampen mechanical shocks, which helps reduce wear and tear during engine operation.

Examples & Analogies

Think of engine lubrication like a dancer performing on stage. Just as dancers need to glide smoothly over the floor to avoid falling and to keep the show running flawlessly, engine parts need lubricants to move smoothly without grinding against each other, preventing damage and ensuring a strong performance.

Properties of an Effective Lubricant

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Properties of an Effective Lubricant

- High Viscosity Index: Maintains adequate thickness over a wide temperature range.

- Thermal Stability: Resists breakdown at high temperatures.

- Oxidation Resistance: Minimizes sludge and deposit formation.

- Detergent and Dispersant Qualities: Keeps engine clean by suspending impurities.

- Low Pour Point: Remains fluid at low temperatures.

- Non-Corrosive and Non-Foaming: Protects engine metals and prevents aeration.

Detailed Explanation

An effective lubricant has several key properties to function properly. A high viscosity index allows it to remain thick enough to protect engine parts at various temperatures. Thermal stability ensures that the lubricant doesn’t break down or become ineffective at high temperatures. Oxidation resistance is critical for preventing the formation of sludge and deposits that can clog or damage engine components. Additionally, good lubricants should include detergent and dispersant properties that help keep the engine clean by suspending impurities within the oil. A low pour point means that the oil stays fluid even in cold temperatures, while being non-corrosive and non-foaming protects the metal parts of the engine.

Examples & Analogies

Consider a well-crafted salad dressing. Just as a good dressing maintains its flavor and texture across different temperatures without separating, a top-quality lubricant maintains its protective abilities despite changes in engine temperature and conditions, ensuring everything mixes well without any unwanted buildup.

Methods of Lubrication

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Methods of Lubrication

- Splash Lubrication: Used in small engines; parts dip into oil sumps and splash oil onto surfaces.

- Pressure (Forced Feed) Lubrication: Oil is pumped under pressure to bearings and critical areas, common in modern automotive engines.

- Combined System: Both splash and pressure methods are used for comprehensive coverage.

- Mist Lubrication: Oil is mixed with fuel (two-stroke engines); lubricates as mixture passes through engine.

Detailed Explanation

There are several methods employed for lubrication in internal combustion engines. Splash lubrication is simple and often used in smaller engines, where components dip into an oil sump and splash oil onto parts. Pressure lubrication, common in modern engines, involves pumping oil under pressure to critical areas to ensure continuous flow and coverage. A combined lubrication system utilizes both splash and pressure methods to improve coverage and reduce wear. Mist lubrication, typically found in two-stroke engines, involves mixing oil with fuel so that the mixture lubricates the engine as it passes through.

Examples & Analogies

Imagine how a shower system works. In one scenario, water sprays over you directly (like pressure lubrication). In another, water from a bucket splashes over your body as you move it (like splash lubrication). Just as you need both methods to stay clean and comfortable, engines benefit from various lubrication methods to reduce wear and maintain performance.

Key Components of the Lubricating System

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Key Components: Oil Filters, Oil Pumps, Oil Coolers

- Oil Filter: Removes wear particles, soot, and contaminants from oil to maintain cleanliness and protect engine longevity.

- Oil Pump: Delivers oil under pressure throughout the engine; typically gear, rotor, or plunger type.

- Oil Cooler: Dissipates excess heat from oil, especially in high-performance or heavy-duty engines, maintaining optimal viscosity and preventing thermal breakdown.

Detailed Explanation

The lubricating system comprises several vital components that work together to ensure optimal engine operation. The oil filter plays a crucial role in maintaining cleanliness by removing particles, soot, and other contaminants from the oil, thereby protecting engine components from damage. The oil pump is responsible for delivering oil under pressure to various engine parts, ensuring that lubrication reaches every critical area. Lastly, the oil cooler helps reduce excess heat from the oil, particularly in high-performance engines, preserving the oil's viscosity and preventing thermal breakdown that could lead to engine failure.

Examples & Analogies

Think of the lubricating system in an engine like the plumbing system in a house. The oil filter is like a sieve that keeps dirt out, the oil pump acts like the water pump that pushes water to where it’s needed, and the oil cooler is like the radiator that keeps the water from getting too hot, ensuring your home runs smoothly without leaks or overheating.

Key Concepts

-

Friction: Resistance that increases wear between moving parts.

-

Viscosity Index: Measurement of how a lubricant's viscosity changes with temperature.

-

Cooling: Essential for preventing overheating of engine components.

-

Lubricant: Substance that reduces friction and serves multiple functions in engines.

-

Key Components: Oil filters, pumps, and coolers are critical for engine longevity.

Examples & Applications

Using multi-grade motor oil in an engine to ensure it performs well in both high and low temperatures.

Implementing a modern pressure-lubricated system that helps distribute oil effectively to all critical components of the engine.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

To keep engines purring, oil should be stirring, cooling, cleaning, and friction curbing.

Stories

Once upon a time in a bustling engine town, the magic oil kept the town running smooth, reducing wear and holding heat at bay.

Memory Tools

Recall the acronym 'F-COOL' for Friction, Cooling, Oil, Out, Lubricate—functions of the lubricant.

Acronyms

Use the word 'VISOR' for Viscosity, Index, Stability, Oxidation Resistance—properties of a lubricant.

Flash Cards

Glossary

- Friction

The resistance encountered when one surface moves over another.

- Viscosity Index

A measure of how viscosity changes with temperature.

- Cooling

The process of removing heat generated by engine operations.

- Lubricant

A substance that reduces friction between surfaces in mutual contact.

- Oil Filter

A device designed to remove contaminants from engine oil.

- Oil Pump

A mechanical device that moves oil through the engine under pressure.

- Oil Cooler

A component that dissipates excess heat from oil.

Reference links

Supplementary resources to enhance your learning experience.