Compressive Strength Test

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Compressive Strength

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we will discuss the compressive strength test, which is key for evaluating the quality of concrete. Can anyone tell me why concrete's compressive strength is so important?

Isn't it important because it tells how much weight concrete can hold?

Exactly! It indicates the maximum load concrete can withstand before failing, which is crucial for any structure. We can remember this with the acronym 'RCC', which stands for 'Really Can Carry' load.

What else does it affect in construction?

Good question! It affects mix design and structural specifications, ensuring safety in construction. Let's move on to what standards we follow when conducting this test.

Compressive Strength Test Standards

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

In India, we refer to IS 516: 1959 for compressive strength tests. In the US, we follow ASTM C39. Why do you think following these standards is important?

It ensures tests are reliable and comparable.

Exactly! Standardized methods help us produce results that are consistent and trustworthy. Can anyone think of why using specific specimen sizes, like cubes and cylinders, is essential?

Maybe it’s to maintain uniformity in results?

Yes! Specific dimensions help ensure that results can be properly compared and interpreted.

Testing Procedure and Calculation

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s go over the testing procedure step-by-step. First, we cast the concrete. Why do we compact concrete in molds?

To remove air pockets and ensure it sets properly!

Great! After casting, we need to cure our specimens correctly. What will happen if we skip curing?

It might not gain the strength we expect, right?

Exactly! After 28 days of curing, we test for compressive strength. Remember the formula? Who can recite it?

It’s f_c = P/A!

Exactly. P is the maximum load, and A is the cross-sectional area. Don’t forget, this is measured in N/mm² or MPa.

Interpreting Results and Importance

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Once we have our results, interpreting them is crucial. Why do you think compressive strength values are vital for structural applications?

They help to determine if the concrete is suitable for constructions.

Correct! If the strength is too low, it might compromise safety. Additionally, knowing how it impacts mix designs is essential. Can anyone give examples of how these tests influence building decisions?

If the concrete isn't strong enough, they might need to change the mix to use higher-grade materials.

Exactly! Stronger mixes lead to safer structures. Now, let's summarize the importance of understanding compressive strength.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section details the compressive strength test performed on hardened concrete, including its objectives, importance, standard codes, procedures, and calculations. It emphasizes the significance of accurate testing for assessing concrete quality and ensuring safe structural design.

Detailed

Compressive Strength Test

The compressive strength test is crucial for evaluating hardened concrete's mechanical properties. This test determines the maximum load a concrete specimen can bear before failure, which is vital for assessing concrete's quality and reliability in structural applications.

Importance of the Test

- Primary Indicator of Quality: Compressive strength is a fundamental characteristic that reflects the quality of the concrete mix.

- Basis for Mix Design: These test results provide necessary feedback for optimizing material usage during mix design, ensuring adequate strength for specific applications.

- Structural Specifications: The test results influence structural design specifications, helping to ensure safety and performance standards are met.

Standard Codes

The test follows defined standards, such as:

- IS 516: 1959: Methods for testing concrete strength in India.

- ASTM C39/C39M: Standard test methods for compressive strength in the USA.

Equipment and Test Specimens

Specimens typically used are:

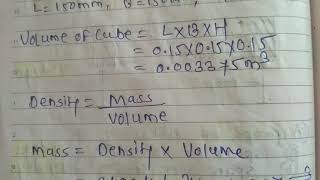

- Cubes: Measuring 150 mm × 150 mm × 150 mm.

- Cylinders: 150 mm in diameter and 300 mm in height.

Testing Procedure

- Casting: Fresh concrete is placed in molds and compacted adequately.

- Curing: Molds are kept in water at controlled temperature for 28 days.

- Testing: Specimens are subjected to a compressive load using a dedicated machine until failure, and the maximum load is recorded.

Calculation of Compressive Strength

The compressive strength (f_c) is calculated using the formula:

$$

f_c = \frac{P}{A}

$$

* Where:

- P = Maximum load (N)

- A = Cross-sectional area (mm²)

Conclusion

Accurate determination of compressive strength is essential for material characterization in construction, guiding decisions on quality control and optimization of concrete mixes.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Objective of the Test

Chapter 1 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

To determine the maximum compressive load a concrete specimen can withstand before failure.

Detailed Explanation

The objective of the compressive strength test is to find out the highest amount of compressive load (force pushing down on the material) that a concrete sample can handle before it breaks or fails. This gives engineers and builders important information about how strong the concrete is, which is crucial for ensuring safety in construction.

Examples & Analogies

Think of it like testing a bridge made of concrete. Just as you would want to know how much weight the bridge can hold before it collapses, knowing the compressive strength helps determine the load the bridge can safely support.

Importance of Compressive Strength

Chapter 2 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Primary indicator of concrete quality.

Basis for mix design and quality control.

Used in structural design specifications.

Detailed Explanation

Compressive strength is essential for several reasons: it acts as the primary measure of concrete quality, helping to assess whether the concrete is suitable for construction. Furthermore, it is used to design the concrete mix, ensuring the correct proportions of materials are used to achieve the desired strength. Finally, compressive strength is vital in engineering specifications, guiding professionals on how to build structures safely.

Examples & Analogies

Imagine baking a cake: the type and amount of ingredients you use determine how well the cake rises and its final structure. Similarly, testing compressive strength ensures the right 'ingredients' in the concrete mix are used, leading to a strong and safe structure.

Standard Codes for Testing

Chapter 3 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

IS 516: 1959 – Methods of Tests for Strength of Concrete.

ASTM C39/C39M – Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens.

Detailed Explanation

Standard codes provide a framework for conducting compressive strength tests in a consistent manner. The IS 516 code outlines methods specific to India, while ASTM C39 is a widely adopted international standard. These codes detail how to prepare samples, conduct tests, and interpret results, ensuring reliability and comparability of test outcomes across different projects.

Examples & Analogies

Think of standard codes as a recipe that tells you exactly how to bake your cake each time. Following the same steps ensures your cake comes out just as good every time, similar to how standard codes ensure consistent quality and strength measurement in concrete testing.

Test Specimens

Chapter 4 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Cubes: 150 mm × 150 mm × 150 mm (as per IS standards).

Cylinders: 150 mm diameter × 300 mm height (as per ASTM).

Detailed Explanation

In compressive strength testing, concrete specimens are prepared in specific shapes and sizes, mainly cubes and cylinders. According to IS standards, cubes measuring 150 mm on each side are commonly used, while ASTM specifies cylindrical specimens with a diameter of 150 mm and a height of 300 mm. These dimensions ensure that the tests are reliable and the results can be compared.

Examples & Analogies

Imagine if you were testing the strength of different types of apples by squeezing them; you would need to ensure each apple was roughly the same size to get a fair comparison. Similarly, having standard sizes for test specimens ensures that the compressive strength of different concrete mixes can be accurately compared.

Equipment Used

Chapter 5 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Compression testing machine (CTM) with calibrated load gauge or digital display.

Tamping rod.

Curing tank.

Detailed Explanation

To conduct the compressive strength test, specific equipment is required. The critical piece of equipment is the Compression Testing Machine (CTM), capable of applying load and accurately measuring how much weight the sample can take. Additional tools, such as a tamping rod for compacting concrete when casting specimens and a curing tank for maintaining proper moisture during the curing process, are also essential.

Examples & Analogies

Consider building a model airplane. You would need specific tools for cutting, assembling, and testing its flight capability. Similarly, the right equipment is crucial for preparing concrete specimens, testing them, and ensuring we get accurate strength measurements.

Testing Procedure

Chapter 6 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Casting: Fresh concrete is placed in moulds in layers and compacted.

- Curing: Specimens are kept in water at 27 ± 2°C for 28 days.

- Testing:

- Remove specimen from curing tank.

- Wipe clean and place in CTM.

- Load is applied at a constant rate until failure.

- Record the maximum load.

Detailed Explanation

The testing procedure involves several careful steps: First, concrete is cast into molds in layers to ensure it is compacted properly. After casting, it is cured in water for 28 days at a controlled temperature. The actual testing starts by taking the cured specimen out, cleaning it, and placing it in the testing machine. A load is then applied gradually until the specimen fails, and the highest load it withstands before breaking is recorded.

Examples & Analogies

Imagine you are preparing a plant for a competition. First, you would carefully pot it in layers to ensure proper growth. Then, you'd nurture it for several weeks before presenting it for judging. Similar to that, concrete needs time and careful handling to ensure it reaches the required strength before testing.

Calculation of Compressive Strength

Chapter 7 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Compressive Strength (f_c) = Maximum Load (P) / Cross-sectional Area (A)

- Units: N/mm² or MPa.

Detailed Explanation

To evaluate the compressive strength, the maximum load (in Newtons) that the specimen can handle is divided by the area over which this load is applied (in square millimeters). The result indicates the strength of the concrete, typically expressed in N/mm² or MPa, which helps engineers determine if the concrete meets required specifications.

Examples & Analogies

If you were testing how much weight a lightweight backpack can carry, you'd measure the total weight it could hold before tearing (the maximum load), and then divide by the area of the material where the load is applied. This gives you an idea of how strong the material is compared to other backpacks.

Key Concepts

-

Compressive Strength Test: A test to evaluate the maximum load a concrete specimen can withstand.

-

Standard Codes: Guidelines such as IS 516 and ASTM C39 that dictate testing procedures.

Examples & Applications

A compressive strength of 25 MPa indicates that the concrete can safely carry loads in structures such as bridges and buildings designed for standard use.

Using a cube specimen for compressive strength testing aligns with IS standards to provide consistent and comparable results.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

In a concrete test, the load must last, or else the structure falls, and that's a blast!

Stories

Imagine a bridge made of concrete. Regularly, engineers test its strength by measuring how much weight it can hold before it cracks or breaks. This ensures safety as vehicles cross each day.

Memory Tools

Remember 'CCM' for Compressive, Cast, Measure - the steps to test concrete!

Acronyms

Use 'SCT' to recall

Standards

Curing

Testing.

Flash Cards

Glossary

- Compressive Strength

The capacity of a concrete specimen to withstand axial loads before failure.

- Curing

The process of maintaining adequate moisture, temperature, and time to allow the concrete to achieve its strength.

- Standard Codes

Established guidelines and protocols for conducting tests and ensuring uniformity.

Reference links

Supplementary resources to enhance your learning experience.