Durability of Construction Materials

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Durability

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're going to explore what durability means in the context of construction materials. Can anyone tell me why durability is important?

It helps materials last longer and maintain their strength over time.

Exactly! Durability is crucial because it ensures our structures remain safe and functional. Now, let’s discuss the main factors that influence durability.

What are some of those factors?

Great question! Factors include environmental exposure, the quality of materials used, our design choices, and the workmanship involved. Remember the acronym 'EDMW': Environment, Design, Material Quality, Workmanship. This will help you recall these key points!

How does environmental exposure affect durability?

Environmental exposure can lead to problems like sulfate attacks or freeze-thaw cycles, which can degrade materials over time. Let’s ensure we grasp why each factor matters as we move forward.

Mechanisms of Durability

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s talk about the mechanisms of durability! Can anyone define what we mean by physical and chemical mechanisms?

I think physical mechanisms relate to the physical stress on materials, like wear and tear?

Correct! Physical mechanisms include things like abrasion and freeze-thaw damage. On the flip side, chemical mechanisms refer to reactions that can cause deterioration. For instance, corrosion of steel reinforcement is a significant issue.

What role do environmental factors play in these mechanisms?

Environmental conditions can accelerate both physical and chemical mechanisms. For instance, in coastal areas, the salt in the air can spur chemical reactions that degrade concrete. Think of it as a two-way street—environment impacts material, and material properties dictate how well it withstands environmental challenges.

Assessing Durability

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, we’ll consider how we can assess durability and permeability. How do you think we can measure these aspects?

Maybe through specific tests on the materials?

Absolutely! There are standardized tests like the Water Permeability Test and the Rapid Chloride Permeability Test we can perform to evaluate these properties.

Why is understanding permeability important for durability?

Great question! Higher permeability can lead to increased water and chloride infiltration, which can undermine durability by promoting processes like corrosion. Keep in mind that lower permeability often correlates with better durability.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section explores durability as a fundamental criterion in civil engineering materials, especially concrete and masonry. Key influences on durability include environmental exposure, material quality, and proper design practices, while detailed mechanisms cover both physical and chemical forms of degradation, underscoring the relationship between durability and permeability.

Detailed

Durability of Construction Materials

Durability is defined as the capability of a material to withstand environmental degradation while retaining its desired engineering properties throughout its anticipated service life. This section elaborates on several key factors influencing durability, such as environmental exposure (e.g., sulfate attack and freeze-thaw effects), material quality (e.g., water-cement ratio and aggregate properties), design and detailing considerations (e.g., cover depth and jointing), workmanship, and maintenance practices.

Key Aspects:

- Durability Mechanisms: These include physical mechanisms like abrasion and freeze-thaw damage, and chemical mechanisms involving corrosion and alkali-silica reactions.

- Understanding how these factors contribute to the overall integrity and longevity of construction materials is crucial to ensuring structural safety and economic feasibility in civil engineering.

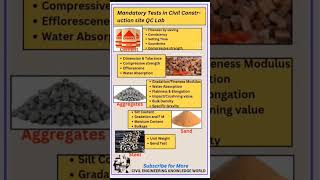

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Definition of Durability

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Durability is defined as the ability of a material to withstand environmental attack and maintain its desired engineering properties over its intended service life without significant degradation.

Detailed Explanation

Durability refers to how well a material can withstand damage from weather, chemicals, and physical wear throughout its expected lifespan. Essentially, it is about the material's ability to remain strong and functional despite environmental challenges. If a material is durable, it won't break down or lose its essential properties over time, which is crucial for structures like buildings and bridges.

Examples & Analogies

Think of durability like a good pair of running shoes. If the shoes are durable, they can withstand rain, mud, and the wear and tear of running on different surfaces without falling apart. Just as you want your shoes to last through many runs without significant damage, materials used in construction need to maintain their integrity over time.

Factors Influencing Durability

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Factors Influencing Durability:

- Environmental Exposure: Sulfate attack, carbonation, chloride ingress, freeze-thaw cycles.

- Material Quality: Water-cement ratio, curing, aggregate properties.

- Design & Detailing: Cover depth, jointing, reinforcement placement.

- Workmanship: Compaction, finishing, curing practices.

- Maintenance Practices: Timely inspection, repair, protection against further damage.

Detailed Explanation

Several factors affect the durability of construction materials:

1. Environmental Exposure refers to how environmental conditions like temperature changes and chemical exposure can damage the material.

2. Material Quality indicates that the specific ratios and properties of the components in the materials can enhance or detract from durability. For example, a lower water-cement ratio generally leads to stronger and more durable concrete.

3. Design & Detailing emphasizes the importance of proper design practices to ensure adequate strength and longevity against stresses.

4. Workmanship is the level of skill and care applied when the materials are mixed and applied—doing it well can significantly enhance durability.

5. Maintenance Practices highlight the need for regular inspections and repairs to prevent small problems from becoming significant issues.

Examples & Analogies

Consider a car as an analogy for durable materials. Just as the durability of a car depends on factors like the quality of materials used, how well it's designed, its maintenance regime, and its resistance to weather, the same is true for construction materials. A well-built car that receives good maintenance lasts longer and performs better, just like durable construction materials do in buildings.

Durability Mechanisms

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Durability Mechanisms:

- Physical mechanisms: Abrasion, freeze-thaw damage, thermal stresses.

- Chemical mechanisms: Corrosion of steel reinforcement, alkali-aggregate reaction (AAR), sulfate attack, carbonation.

Detailed Explanation

Durability mechanisms refer to the processes that can cause materials to degrade over time. Physical mechanisms such as abrasion and freeze-thaw damage happen through repeated wear and environmental changes, like water freezing and expanding inside the material.

Chemical mechanisms are related to reactions that occur within the material or between the material and its environment. For example, rusting of steel reinforcement inside concrete due to moisture is a chemical mechanism. Understanding these mechanisms helps engineers design better materials that can resist these types of damage.

Examples & Analogies

You can think of durability mechanisms in the same way you think about a good winter coat. The coat protects you from wind and cold just as durable materials protect buildings from environmental damage. However, over time, wear and tear from daily use (physical mechanisms) and exposure to harsh conditions (like salt from icy roads causing chemical reactions) can compromise the coat's effectiveness, much like how construction materials can degrade.

Key Concepts

-

Environmental Exposure: Factors like sulfate attack or freeze-thaw cycles that can influence material longevity.

-

Material Quality: The inherent characteristics of the materials used, including the mix proportions and the selection of aggregates.

-

Design and Detailing: Design choices, including the depth of concrete cover and joint layout, affect durability.

-

Workmanship: The quality of construction practices impacts the long-term durability of the material.

-

Permeability-Durability Relationship: Higher permeability often leads to reduced durability due to increased susceptibility to damage.

Examples & Applications

A concrete structure in a coastal region may suffer from chloride ion attacks due to seawater exposure, leading to corrosion.

Proper curing techniques following the placement of concrete can significantly improve its durability and resistance to cracking.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Rigorous rain or frosty freeze, a durable mix will weather with ease!

Stories

Imagine a bridge in a coastal town, exposed to salty air and waves, with a strong, durable concrete protecting the rebar inside, ensuring safety for years to come.

Memory Tools

Remember 'E-D-M-W' for factors affecting durability: Environment, Design, Material Quality, Workmanship.

Acronyms

DURABLE - Deteriorate Less Under Real-world Attacks By Land and Environmental factors.

Flash Cards

Glossary

- Durability

The ability of a material to withstand environmental attack and maintain its engineering properties over time.

- Permeability

The capacity of a material to allow fluids or gases to pass through its pore system.

- WaterCement Ratio

The ratio of the weight of water to the weight of cement used in a concrete mix, affecting strength and durability.

- Sulfate Attack

A chemical reaction between sulfate ions in water and the hydration products of cement, leading to expansion and cracking.

- Corrosion

The deterioration of materials, often metals, due to chemical reactions, such as oxidation in the presence of moisture.

- Capillary Action

The ability of water to move through a porous material due to surface tension; significant in assessing permeability.

Reference links

Supplementary resources to enhance your learning experience.