Physical Properties of Aluminum

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Atomic and Crystalline Structure

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're going to start by discussing the atomic and crystalline structure of aluminum. Do you know what makes its structure unique?

Is it because it has a face-centered cubic structure?

Exactly! The face-centered cubic or FCC structure contributes to its excellent formability. Aluminum is very ductile. Can anyone tell me about its atomic number?

The atomic number is 13!

Right! And do you remember aluminum's density?

It's about 2.7 g/cm³.

Nicely done! Its low density is one reason it's used in many applications.

Appearance of Aluminum

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let's explore aluminum's appearance. How would you describe it?

It’s silvery-white and can be polished.

Correct! It can also be anodized. Why do you think this feature is important?

Anodizing makes it more resistant to corrosion!

Exactly! The natural oxide layer also helps protect it from further oxidation.

Thermal and Electrical Conductivity

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's focus on thermal and electrical conductivity now. Can anyone tell me about aluminum's thermal conductivity?

It’s around 235 W/m·K.

Correct! And how does this compare to its electrical conductivity?

It has about 63% of copper's conductivity.

Excellent! This makes aluminum a preferred choice for overhead power lines because of its lower density. Let's wrap up with why these properties matter.

They enhance aluminum's utility in various applications where weight and efficiency are crucial!

Well said! Remember these concepts as they are crucial for understanding aluminum’s role in engineering.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

In this section, we explore aluminum's atomic and crystalline structure, appearance, as well as its thermal and electrical conductivity. Key properties like density and melting/boiling points are examined, highlighting the advantages that these characteristics provide in engineering applications.

Detailed

Physical Properties of Aluminum

Aluminum is one of the most abundant metals and has unique physical properties that make it essential in engineering. This section covers:

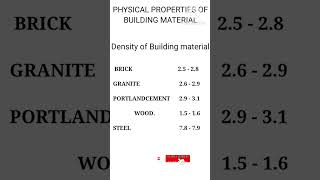

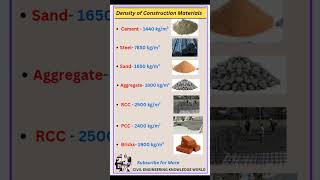

- Atomic and Crystalline Structure: The atomic number, atomic weight, face-centered cubic (FCC) structure, density, melting point, and boiling point are discussed. The FCC structure contributes significantly to its formability and ductility, enabling easy cold work compared to body-centered cubic (BCC) metals.

- Appearance: Describes aluminum's silvery-white appearance, its ability to be polished to a high sheen or anodized for a matte finish, and the formation of a natural oxide layer that enhances its oxidation resistance.

- Thermal and Electrical Conductivity: Highlights how aluminum's thermal conductivity is approximately 235 W/m·K and its electrical conductivity, while 63% of copper, makes it invaluable, especially in overhead power lines due to its lower density.

These physical properties underline aluminum's increasing importance in construction and engineering, especially where weight and corrosion resistance are pivotal.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Atomic and Crystalline Structure

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Atomic number: 13

- Atomic weight: 26.98

- Crystal structure: Face-Centered Cubic (FCC)

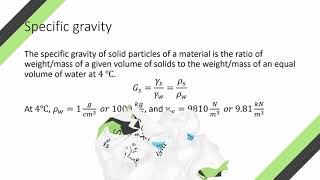

- Density: ~2.7 g/cm³

- Melting point: 660°C

- Boiling point: ~2,470°C

The FCC structure contributes to its excellent formability and ductility. Unlike BCC metals, aluminum can be cold-worked easily.

Detailed Explanation

This chunk introduces fundamental physical characteristics of aluminum, starting with its atomic number (13) and atomic weight (26.98), which indicates its identity as a chemical element. The 'Face-Centered Cubic (FCC)' structure is a specific arrangement of atoms in the solid state that allows aluminum to be very malleable and ductile. Additionally, the density is about 2.7 g/cm³, much lighter than many other metals, and the melting and boiling points show that aluminum can withstand high temperatures before transitioning to liquid form. Understanding the crystalline structure is crucial because it directly influences how aluminum behaves when manufactured or formed into products, making it versatile in applications where shaping and manipulation are necessary.

Examples & Analogies

Think of aluminum as a box of LEGO bricks. Just as certain configurations of LEGO bricks can be very strong and flexible, the FCC arrangement of aluminum atoms gives it strength and the ability to be shaped and bent without breaking. This property is what allows builders to create intricate and lightweight structures, similar to how you might build a detailed model with flexible LEGO designs.

Appearance

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Silvery-white in appearance.

- Can be polished to a high sheen or anodized to a matte finish.

- Forms a natural oxide film that protects it from further oxidation.

Detailed Explanation

Aluminum has a distinct silvery-white color, which is characteristic of many metals. This visual aspect can be enhanced through processes such as polishing, which makes it shiny and reflective, or anodizing, which gives it a matte finish. Anodizing is particularly important in protecting aluminum, as it encourages the formation of a layer of aluminum oxide on its surface. This oxide layer acts like a shield, preventing further corrosion, much like how paint protects wood from rotting. Thus, the appearance and surface treatment of aluminum not only fulfill aesthetic purposes but also enhance its durability in various environments.

Examples & Analogies

Consider a shiny apple versus one that's been left out too long and starts to brown. The shiny apple represents polished aluminum, looking good and protected, while the brown apple represents untreated aluminum that could get damaged. Just as we use coatings to keep food fresh and appealing, we use anodizing to keep aluminum robust and visually pleasing.

Thermal and Electrical Conductivity

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Thermal conductivity: ~235 W/m·K

- Electrical conductivity: ~63% of copper (but due to its lower density, it's often preferred for overhead power lines).

Detailed Explanation

This section highlights aluminum's impressive thermal and electrical conductivity. With a thermal conductivity rating of approximately 235 W/m·K, it conducts heat effectively, making it suitable for applications where heat dissipation is essential. In terms of electrical conductivity, aluminum conducts about 63% as well as copper; however, its lighter weight makes it a more favorable choice for overhead power lines where reducing weight is important. Consequently, aluminum can be found in many electrical applications, such as wiring and heat exchangers, because it provides efficient conduction without adding excess weight.

Examples & Analogies

Imagine you have two different cooking pans: one made of aluminum and another made of copper. While copper is the star when it comes to heat conduction, aluminum, being lighter and still good at conducting heat, helps when you need pans that won't weigh you down while cooking. This analogy highlights why aluminum is frequently used in overhead power lines – it’s efficient and minimally burdensome!

Key Concepts

-

Atomic Structure: Aluminum has an atomic number of 13 and exhibits a face-centered cubic (FCC) structure enhancing its ductility.

-

Appearance: Aluminum is silvery-white, can be polished or anodized, with a natural oxide layer for corrosion resistance.

-

Conductivity: It has high thermal conductivity (~235 W/m·K) and good electrical conductivity (~63% of copper), making it suitable for various applications.

Examples & Applications

Aluminum's ability to form a lightweight aircraft fuselage due to its strength-to-weight ratio.

The use of aluminum in electrical wiring, particularly in overhead power lines, to reduce weight while maintaining conductivity.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Aluminum's number is thirteen, sparkling bright and clean.

Stories

Imagine a shiny silver knight, with a coat that cannot rust; it's strong and light, just like aluminum.

Memory Tools

A for Atomic, F for Face-centered, D for Ductility - remember 'AFD' for aluminum's properties.

Acronyms

A.C.E. - Aluminum's Conductivity, Appearance, Endurance.

Flash Cards

Glossary

- Atomic Number

The number of protons in the nucleus of an atom, determining its chemical properties.

- FaceCentered Cubic (FCC)

A type of crystal structure where atoms are located at each corner and in the center of each face of the cube.

- Ductility

The ability of a material to deform under tensile stress; often characterized by the material's ability to be stretched into a wire.

- Oxide Layer

A thin layer of oxide that forms on metals, providing protection against further oxidation.

- Thermal Conductivity

The ability of a material to conduct heat.

- Electrical Conductivity

The ability of a material to conduct electricity.

Reference links

Supplementary resources to enhance your learning experience.