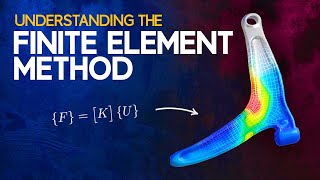

Introduction to the Finite Element Method (FEM/FES)

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to FEM

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today we'll dive into the Finite Element Method, commonly referred to as FEM. It's a numerical technique designed to solve complex physical problems by breaking them down into finite smaller parts. Can anyone tell me why breaking something down into smaller parts might be useful?

It makes it easier to analyze and compute solutions.

Yeah! Different parts might behave differently under load!

Exactly! By analyzing each small element, we can create a more accurate representation of the whole system. Remember that concept with the acronym 'SIMPLE': S, Solve; I, Identify parts; M, Mesh; P, Process; L, Load; E, Evaluate!

Got it! That’s a good way to remember it!

Great! To summarize, FEM disintegrates complex problems into manageable parts which we can then solve iteratively.

Applications of FEM

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's talk about where FEM is used. It’s applicable in structural analysis, thermal analysis, and even fluid dynamics. Can someone provide an example of each of these?

For structural analysis, maybe in designing bridges?

And for thermal analysis, checking heat distribution in engine parts?

Fluid dynamics would be like simulating airflow over an airplane wing!

Exactly! These examples give us an idea of the versatility of FEM across various sectors. To remember these applications, think of the mnemonic 'STF': S for Structural, T for Thermal, and F for Fluid Dynamics!

I’ll write that down!

Wonderful! In summary, FEM is fundamental in various domains due to its adaptability and comprehensive approach.

Principle of Potential Energy

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s now focus on the principle of potential energy. What does this principle state?

It says that a system in equilibrium will have a minimum total potential energy.

And it helps derive the stiffness equations, right?

Correct! The total potential energy can be expressed as the strain energy minus the work done by the applied loads. We can derive our finite element equations from variations of this energy. An easy way to remember this is with 'PE = SE - WD', where PE is Potential Energy, SE is Strain Energy, and WD is Work Done.

That's easy to recall!

Excellent! In summary, understanding the principle of potential energy is crucial for developing accurate models in FEM.

Finite Element Analysis of 1D Elements

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

We now move to the finite element analysis of 1D elements. What are the common 1D elements we analyze using FEM?

Spring, bar, and truss elements!

Exactly! Can anyone explain how the element stiffness matrix for a spring element is derived?

It’s based on the displacement-based approach and uses Hooke’s Law for axial loading!

Correct! The same principles apply to bars and trusses, factoring their different loading conditions. Remember: 'SPB' for Spring, Bar, Truss as the order of analysis to keep them distinct!

That's helpful!

In summary, understanding these elements' specific characteristics is vital for accurate modeling and analysis in FEM.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section discusses the Finite Element Method (FEM), highlighting its applications in engineering analysis, including structural, thermal, and fluid dynamics problems. Key concepts such as the principle of potential energy, 1D element problem formulations, and the importance of domain discretization and validation in FEM are covered.

Detailed

Introduction to the Finite Element Method (FEM/FES)

The Finite Element Method (FEM) is a powerful numerical technique utilized in engineering analysis to solve differential equations governing complex physical systems. This section encompasses various aspects of FEM, focusing on its application in 1D element problems such as springs, bars, and trusses and introduces the principle of potential energy in formulating element stiffness equations.

Key Concepts:

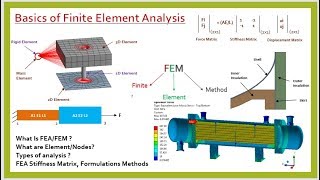

- Finite Element Method (FEM): A numerical technique that divides a physical structure into simple geometrical shapes (finite elements) to approximate solutions of complex differential equations.

- Applications: FEM is widely applied in structural analysis, thermal analysis, dynamic analysis, and fluid flow problems.

- Principle of Potential Energy: A fundamental concept stating that a system in equilibrium has a minimum potential energy. This principle is essential in developing stiffness equations in FEM.

- Finite Element Analysis (FEA) of 1D Elements: Covers formulations and uses of different elements, including spring, bar, and truss elements, under various loads and conditions.

- Global Stiffness Matrix Assembly: Discusses how individual element stiffness matrices are combined into a global matrix while accommodating boundary conditions to solve structural problems.

- Plane Stress and Plane Strain Problems: Differentiating between two-dimensional stress states for thin plates versus long structures, which informs the selection of appropriate elements in FEM.

- Domain Discretization: This involves dividing the model into smaller elements (meshing) for analysis accuracy.

- Verification and Validation (V&V): Ensures the reliability and accuracy of models through computational checking and experimental comparisons.

- Popular CAE Software: Introduces various software tools widely used in industry for applying FEM, emphasizing ANSYS, Abaqus, and SolidWorks Simulation.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

What is FEM?

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

A numerical technique used to solve differential equations and approximate solutions for complex physical systems.

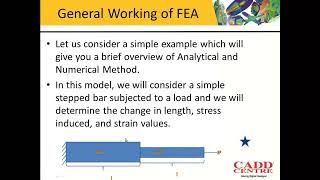

Divides the domain into finite smaller elements, solves for each element, and assembles the global solution.

Detailed Explanation

The Finite Element Method (FEM) is a powerful numerical technique that engineers use to find approximate solutions for complex physical problems. In essence, FEM breaks down a large, complicated model into smaller, more manageable pieces called 'elements'. Each of these elements is solved individually for its behavior under specific conditions. Once all the elements are solved, the results are combined to form an overall solution for the entire model. This method allows for solving differential equations that describe physical phenomena, such as how structures deform under load or how heat flows through materials.

Examples & Analogies

Imagine trying to understand how a large jigsaw puzzle fits together. If you look at the entire puzzle at once, it's challenging to see how each piece fits. However, if you focus on individual pieces and how they connect, you'll get a clearer picture. Similarly, FEM helps engineers tackle complex problems by analyzing small parts (elements) before piecing together the whole solution.

Applications of FEM

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Applications:

- Structural analysis

- Thermal analysis

- Dynamic and vibration analysis

- Fluid flow – CFD using FVM/FE

- Electromagnetic field simulation

Detailed Explanation

FEM has a wide range of applications across various engineering fields. It is extensively used in structural analysis to understand how different materials and structures behave under loads and stress. Engineers use FEM for thermal analysis to predict temperature distributions in materials. In dynamic and vibration analysis, FEM helps assess how structures respond to forces that can cause movement. Furthermore, in fluid dynamics, FEM can simulate fluid flow through different geometries. Lastly, it is valuable in electromagnetic field simulation, allowing engineers to understand how electric and magnetic fields interact with materials.

Examples & Analogies

Think of a bridge. Before it is constructed, engineers need to make sure it can handle vehicles passing over it. They simulate various scenarios: what happens when a heavy truck crosses? Is the bridge stable? FEM allows engineers to test these scenarios virtually, similar to how video game designers simulate different character behaviors in a game.

Key Concepts

-

Finite Element Method (FEM): A numerical technique that divides a physical structure into simple geometrical shapes (finite elements) to approximate solutions of complex differential equations.

-

Applications: FEM is widely applied in structural analysis, thermal analysis, dynamic analysis, and fluid flow problems.

-

Principle of Potential Energy: A fundamental concept stating that a system in equilibrium has a minimum potential energy. This principle is essential in developing stiffness equations in FEM.

-

Finite Element Analysis (FEA) of 1D Elements: Covers formulations and uses of different elements, including spring, bar, and truss elements, under various loads and conditions.

-

Global Stiffness Matrix Assembly: Discusses how individual element stiffness matrices are combined into a global matrix while accommodating boundary conditions to solve structural problems.

-

Plane Stress and Plane Strain Problems: Differentiating between two-dimensional stress states for thin plates versus long structures, which informs the selection of appropriate elements in FEM.

-

Domain Discretization: This involves dividing the model into smaller elements (meshing) for analysis accuracy.

-

Verification and Validation (V&V): Ensures the reliability and accuracy of models through computational checking and experimental comparisons.

-

Popular CAE Software: Introduces various software tools widely used in industry for applying FEM, emphasizing ANSYS, Abaqus, and SolidWorks Simulation.

Examples & Applications

FEM is used in designing aircraft wings to predict stress distributions under aerodynamic loads.

Thermal FEM can simulate temperature changes in electronic components during operation.

Fluid dynamics simulations in automotive design can illustrate airflow patterns across vehicle profiles using FEM techniques.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

FEM goes from big to small, solves problems when we call!

Stories

Imagine you’re building a bridge. Before actually constructing, you divide the bridge into smaller parts to understand how each segment will bear the load – that’s FEM in action.

Memory Tools

'STF' for Structural, Thermal, and Fluid applications of FEM.

Acronyms

'SIMPLE' for the steps in FEM

Solve

Identify

Mesh

Process

Load

Evaluate.

Flash Cards

Glossary

- Finite Element Method (FEM)

A numerical technique for finding approximate solutions to complex physical problems by dividing them into smaller, simpler parts called finite elements.

- Principle of Potential Energy (PPE)

States that a system in equilibrium has minimum potential energy, essential for formulating element stiffness equations in FEM.

- Element Stiffness Matrix

A representation of how an individual element resists deformation under applied force or displacement.

- Domain Discretization

The process of dividing a physical model into smaller parts or elements for analysis.

- Validation and Verification (V&V)

Verification ensures the computational model is correctly solved, while validation ensures it accurately represents the real-world problem.

Reference links

Supplementary resources to enhance your learning experience.