Criteria for Chemical Selection

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Chemical Modification

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we will talk about chemical soil modification and stabilization, which involves adding substances like lime, cement, or fly ash to improve soil properties. Can anyone tell me why we modify soil?

To make it stronger and more stable for construction, right?

Exactly! By modifying soil, we increase its strength and reduce issues like shrink/swell potential. Does anyone remember the two main mechanisms by which these chemicals work?

One is cementation, and the other is moisture absorption?

Correct! Cementation increases particle size and internal friction, resulting in greater shear strength. Can you visualize how this might help in a pavement project?

It makes the base stronger, which means the pavement won’t crack as easily.

Great connection! Let's move into specifics about the chemicals and the design procedures.

Design Procedures for Chemical Selection

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

When selecting chemicals for soil modification, we need to understand their reactivity. For lime stabilization, we often use a specific test method. Who can tell me what that is?

Is it the unconfined compression strength test?

Yes! We prepare soil specimens, adding at least 5% quick lime, and test for unconfined compressive strength. What do we expect as the minimum strength gain?

50 psi over the natural soil?

Correct! And for cement stabilization, what strength gain are we looking for?

100 psi with 4% cement.

Spot on! These tests ensure that our soil modification is effective. Let’s summarize what we’ve learned.

Understanding Strength Requirements

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s dive into strength requirements. Why do you think it’s important for a treated soil to meet certain strength gains?

It’s to ensure that the soil has the right load-bearing capacity.

Exactly! For construction projects, insufficient strength can lead to failures like cracking or compaction issues. What’s the acceptable strength increase for soil modified with a mix of chemicals?

It should achieve at least 30 psi over the natural soil.

Right! Achieving these requirements ensures better stability and support. How does this apply to road construction?

The roads would last longer and require less maintenance!

Great analysis! Remember, selecting the right chemical mix can dramatically impact the performance of the soil.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The criteria for chemical selection in soil stabilization involves evaluating soil index properties and determining the appropriate chemical quantities needed to achieve desired strength gains. This includes understanding the reactivity of soil with lime and cement and other chemicals to ensure effective stabilization.

Detailed

Criteria for Chemical Selection

This section outlines the fundamental criteria that should guide the selection of chemicals used for modifying or stabilizing subgrade soils. Understanding these criteria is crucial for achieving the required strength and stability in construction projects involving soil treatments.

- Mechanisms of Stabilization: Chemicals such as lime, cement, and fly ash alter soil properties primarily through two mechanisms:

- Cementation: Increases particle size and shear strength while reducing plasticity index and shrink/swell potential.

- Moisture Control: Enhances moisture absorption and binding, facilitating better compaction.

- Design Procedures and Strength Requirements: For effective chemical stabilization, the change in soil strength post-treatment must be significant. The methodology includes:

- Testing: Evaluate soil reactivity through unconfined compression strength tests after treatment with specific chemical amounts (e.g., 5% quick lime).

- Strength Gain: A minimum strength gain of 50 psi for lime-treated soils and 100 psi for cement-treated soils compared to natural soil is required for adequate stabilization.

- Chemical Combinations: The selection may also involve combinations of approved chemicals like LKD, cement, and Class C fly ash to achieve the necessary strength increases of around 30 psi for stabilization after testing.

Understanding these criteria helps ensure that the selected chemicals provide effective soil modification or stabilization for construction applications.

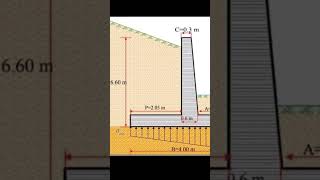

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Overview of Chemical Stabilization

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

When the chemical stabilization or modification of subgrade soils is considered as the most economical or feasible alternate, the following criteria should be considered for chemical selection based on index properties of the soils.

Detailed Explanation

This introductory statement highlights the importance of chemical stabilization or modification for improving subgrade soils. When engineers decide to use chemicals, they evaluate their options based on how well those chemicals will work with the specific properties of the soil. This evaluation ensures that the selected chemical is effective and economical for the project.

Examples & Analogies

Think of it like choosing the right fertilizer for different plants in a garden. Just as certain fertilizers work better for specific plants based on their needs, chemicals for soil stabilization must be selected based on the soil's characteristics to achieve the best results.

Strength Requirements for Stabilization

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The reaction of a soil with quick lime, or cement is important for stabilization or modification and design methodology. The methodology shall be based on an increase in the unconfined compression strength test data.

Detailed Explanation

This chunk emphasizes that the interaction between soil and chemicals like quick lime or cement is crucial for effective stabilization. Engineers perform tests to measure the strength of the soil after treatment, indicating how well the soil has been stabilized. The increase in the unconfined compression strength helps determine if the chosen chemical is effective for that particular soil.

Examples & Analogies

Imagine baking a cake: if you add the right amount of baking powder (analogous to the right chemical), the cake rises and becomes fluffy (the soil gains strength). Just like baking, where you check whether the cake has risen enough, engineers test the soil to ensure it has achieved sufficient strength.

Specimen Preparation for Testing

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

To determine the reactivity of the soils for lime stabilization, a pair of specimens measuring 2 in. (50 mm) diameter by 4 in. (100 mm) height (prepared by mixing at least 5% quick lime by dry weight of the natural soil) are prepared at the optimum moisture content and maximum dry density (AASHTO T 99). Cure the specimens for 48 hours at 120o F (50o C) in the laboratory and test as per AASHTO T 208.

Detailed Explanation

In this section, a detailed process for preparing test specimens is outlined. The dimensions of the specimens are specified, along with the amount of quick lime to be mixed with the soil. This preparation is crucial because it simulates real-world conditions under which the soil would be stabilized. The curing process and testing standards also ensure that results are consistent and reliable.

Examples & Analogies

Consider this preparation like setting up a science experiment in a classroom. You need to measure the materials precisely and follow specific steps (like curing at the right temperature) to ensure your experiment (soil stabilization) works correctly. If you do not follow the steps, you may not get the results you want.

Strength Gain Requirements

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The strength gain of lime soil mixture must be at least 50 psi (350 kPa) greater than the natural soils. A strength gain of 100 psi (700 kPa) for a soil-cement mixture over the natural soil shall be considered adequate for cement stabilization with 4% cement by dry weight of the soils and tested as described above.

Detailed Explanation

This section specifies the minimum strength requirements for the soil after stabilization. For lime-treated soil, there should be a gain of 50 psi in strength compared to the untreated soil. When using cement, a 100 psi gain is needed to confirm that cement stabilization is effective. This ensures that the stabilized soil is significantly stronger than before treatment.

Examples & Analogies

Think of this as needing a certain score to pass a class. Just like a student needs a high enough score to pass (gain strength), the soil needs to show a specified increase in strength to be considered successfully stabilized. If it doesn't meet these requirements, it’s like failing the class.

Chemical Combination Approvals

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

In the case of soil Stabilization, enhanced subgrade support is not accounted for in pavement design. However, an approved chemical (LKD, cement, and fly ash class C) or a combination of the chemicals shall attain an increase in strength of 30 psi over the natural soils when specimens are prepared and tested in the same manner as stabilization.

Detailed Explanation

This chunk addresses the limitations in pavement design when considering soil stabilization. It highlights that while some chemical combinations are approved, they must still show a minimum increase in strength (30 psi) over the untreated soil. This ensures the stability of pavement designs based on the treated subgrade's performance.

Examples & Analogies

Imagine building a bridge: engineers must ensure the materials used can support the weight of traffic. If certain chemicals (like LKD, cement, and fly ash) are used, they must still be tested to ensure they provide enough support, just like the bridge materials must be tested to ensure they can safely hold the weight.

Key Concepts

-

Chemical Modification: Adding chemicals like lime, cement, or fly ash to enhance soil properties.

-

Cementation: The process of binding soil particles to increase strength.

-

Moisture Binding: The ability of chemicals to help soil absorb and retain moisture.

-

Strength Gain: The improvement in compressive strength after chemical treatment, essential for stability.

Examples & Applications

Adding 5% lime to a clay soil to increase its compressive strength from 100 psi to 150 psi.

Using 4% cement for a sandy subgrade, improving its stability significantly for road construction.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

For soil that's tough and strong, add cement or lime, it won't be wrong.

Stories

Imagine a builder who faced soft soil. He added cement and lime, transforming the base into a solid foundation, ready for a robust road.

Memory Tools

C.M.S. - Cement, Moisture, Strength (to remember key aspects of soil modification).

Acronyms

L.M.C. - Lime for Moisture Control (to emphasize lime’s role in binding moisture).

Flash Cards

Glossary

- Chemical Stabilization

The process of adding chemicals to soil to improve its physical and mechanical properties.

- Cementation

The binding of soil particles through chemical reactions, resulting in increased strength.

- Moisture Absorption

The capacity of soil to bind water, affecting compaction and stability.

- Unconfined Compression Strength Test

A test to measure the compressive strength of soil specimens under no lateral support.

- Quick Lime

A chemical used for soil stabilization that helps in cementation.

Reference links

Supplementary resources to enhance your learning experience.