Extrusion-Based Processes

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Extrusion-Based Processes

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Welcome everyone! Today, we’re diving into extrusion-based processes, which are fundamental in additive manufacturing. Can anyone tell me what these processes involve?

Is it about building things layer by layer?

That’s correct! Specifically, we commonly use technologies like Fused Deposition Modeling, or FDM. Why do you think this method is popular?

Maybe because it’s cheaper and easier to set up?

Exactly! And it has a wide range of materials available. FDM typically uses thermoplastics like PLA or ABS. These materials define its applications. Who can name one application where FDM is used?

Prototyping, right?

Yes! FDM is often used for prototypes and educational models. Let's summarize: we discussed the process, materials, applications, and advantages like cost-effectiveness. Any questions?

Advantages and Limitations of FDM

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now that we have a basic understanding of FDM, let’s explore its advantages and limitations. Can someone outline a key advantage?

I think the cost is a big advantage!

Absolutely! It's one of the least expensive methods. What about a limitation?

I remember learning about visible layer lines as a drawback.

Correct! Those layer lines can affect aesthetics and accuracy. Let's summarize those points again. We can use the acronym 'CAVE' for Cost-Advantages, Visible lines, and Ease of use.

Materials Used in FDM

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s talk about materials used in FDM. Can anyone list the common filaments?

PLA and ABS are the most popular ones!

Yes! PLA is known for being biodegradable and easy to print with, while ABS is stronger and impact-resistant. Both have their places in prototyping. What about a more specialized filament?

Composite filaments, like those mixed with carbon fiber?

Yes! These composites enhance strength and durability, making them great for functional parts. Remember, choosing the right material is crucial for your project's success.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Extrusion-based processes, particularly Fused Deposition Modeling (FDM) and Fused Filament Fabrication (FFF), involve melting thermoplastic filaments to build objects layer by layer. This section covers the materials used, applications, advantages, and limitations of these techniques.

Detailed

Extrusion-Based Processes in Additive Manufacturing

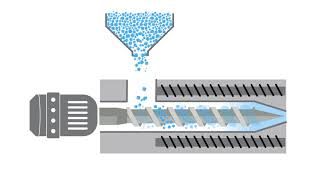

Extrusion-based processes, such as Fused Deposition Modeling (FDM) and Fused Filament Fabrication (FFF), are pivotal techniques within additive manufacturing (AM). These methods utilize thermoplastic filaments, melted and extruded through a heated nozzle to construct objects layer by layer, directly from a digital model.

Key Aspects of Extrusion-Based Processes

- Materials: The most common materials include PLA, ABS, PETG, nylon, and various composite filaments, offering a versatile range for different applications.

- Applications: Ideal for creating prototypes, educational models, and jigs and fixtures, these processes cater to diverse needs.

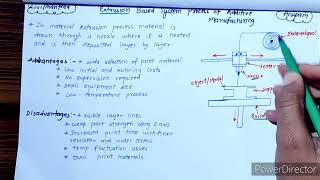

- Advantages: Extrusion-based techniques are known for their low cost, ease of use, and broad material availability, making them accessible for beginners and professionals alike.

- Limitations: However, they are sometimes criticized for visible layer lines, limited accuracy, and moderate strength, which may not be suitable for all applications.

As additive manufacturing evolves, understanding the strengths and weaknesses of extrusion-based processes remains critical for selecting appropriate methods for design and production.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Overview of Fused Deposition Modeling (FDM)

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Process: Thermoplastic filament is melted and extruded through a heated nozzle to build parts layer by layer.

Detailed Explanation

Fused Deposition Modeling (FDM) is a popular 3D printing method where a long filament of thermoplastic material is heated until it melts. This melted material is then forced out through a nozzle, which moves in coordinated paths to create an object layer by layer. Each layer solidifies as it cools, forming a solid part over time.

Examples & Analogies

Think of FDM like a hot glue gun. When you pull the trigger, the glue comes out in a continuous string. If you move the nozzle around, you can create shapes layer by layer. Just like how the glue cools and hardens into place, FDM uses melted plastic that solidifies into a final form.

Materials Used in FDM

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Materials: PLA, ABS, PETG, Nylon, composite filaments.

Detailed Explanation

FDM can use various materials, primarily thermoplastics. Each material has unique properties: PLA is biodegradable and easy to work with, ABS is strong and heat-resistant, PETG has excellent durability, Nylon is flexible, and composite filaments can include materials like carbon fiber for added strength. The choice of material affects the properties of the final printed object.

Examples & Analogies

Choosing the right filament for 3D printing is like picking paint for a wall. Just as there are different types of paint (matte, glossy, waterproof), there are different types of filaments, each suited for specific jobs, depending on whether you need something durable or easy to mold.

Applications of FDM

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Applications: Prototypes, educational models, jigs and fixtures.

Detailed Explanation

FDM is widely used in various fields. It is ideal for creating prototypes, which are preliminary models of products that help designers test ideas quickly. Educational institutions use FDM to create models for teaching purposes. Jigs and fixtures, which help in manufacturing or assembly processes, are also commonly made with FDM due to the simplicity and efficiency.

Examples & Analogies

Imagine if you're developing a new product, like a toy. Using FDM to make a prototype is like sketching your ideas on paper before you create the final version. It allows you to visualize and make changes before you invest time and resources into making the actual product.

Advantages of FDM

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Advantages: Inexpensive and easy to use; Broad material availability.

Detailed Explanation

One of the main advantages of FDM is that it is relatively inexpensive compared to other 3D printing methods. The printers themselves are often affordable, and the materials are widely available and vary in price. Additionally, FDM printers are user-friendly, making them suitable for beginners and experienced users alike.

- Chunk Title: Limitations of FDM

- Chunk Text: Limitations: Visible layer lines; Limited to moderate accuracy and strength.

- Detailed Explanation: Despite its advantages, FDM has limitations. One common issue is the visible layer lines on the surface of printed objects, which can affect the aesthetic quality. Moreover, FDM prints are generally not as strong or precise as those made with some other methods, which can be a concern in applications requiring high durability or specificity.

Examples & Analogies

Think of FDM prints as a rough draft of a book. Just like a rough draft has mistakes and doesn't look polished, FDM prints can show imperfections that you might want to improve upon in a final version. In situations where strength and precision are critical, more advanced methods might be necessary.

Key Concepts

-

Fused Deposition Modeling (FDM): A process in which thermoplastic material is melted and deposited in layers to create an object.

-

Thermoplastics: Plastics that become moldable upon heating and solidify upon cooling, vital for FDM.

-

Applications: Various uses of FDM, including prototyping and educational models.

-

Materials used: Common materials such as PLA, ABS, and composite filaments.

Examples & Applications

An example of FDM application: Creating a prototype for a new product, such as a smartphone case using PLA.

An educational model made from ABS demonstrating structural integrity in construction applications.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

FDM, layer by layer, building your design; thermoplastics melt and join in a line.

Stories

Imagine a sculptor who gently melts wax and drips it in layers, creating a beautiful statue; that's how FDM works with thermoplastics!

Memory Tools

Remember FDM with 'Filaments Deposed Masterfully' for understanding layering.

Acronyms

Use 'P.A.C.T.' to remember

Prototyping

Affordable

Composite materials

Thermoplastics.

Flash Cards

Glossary

- Fused Deposition Modeling (FDM)

A 3D printing process that involves melting thermoplastic filament and extruding it through a hot nozzle to build parts layer by layer.

- Thermoplastic

A type of plastic that becomes pliable or moldable above a specific temperature and solidifies upon cooling.

- Prototyping

The process of creating an early model of a product to test concepts and functionality.

- PLA

Polylactic Acid, a biodegradable thermoplastic commonly used in 3D printing.

- ABS

Acrylonitrile Butadiene Styrene, a strong thermoplastic used for its durability in 3D printing.

- Composite Filament

A filament that is blended with other materials, such as carbon fiber or metal, to enhance its properties.

Reference links

Supplementary resources to enhance your learning experience.