Common Material Removal (Machining) Processes

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Turning Process

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we will start with the turning process. Turning involves rotating a workpiece while a single-point cutting tool removes material. Can any of you tell me what machines are typically used for turning?

Is it a lathe?

Exactly! A lathe is essential for turning operations. Now, what kinds of parts do you think we can create using turning?

Like shafts or rods?

Correct! Shafts, rods, and even disc-type components can be manufactured this way. Remember the acronym ‘TSP’ for Turning, Shafts, and Parts. Any questions?

Drilling and Its Applications

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's move to drilling. Drilling uses a multi-point cutting tool. Can you name any specific actions performed during drilling?

Reaming and tapping?

Great job! Both reaming and tapping are specific drilling operations. They help refine holes for fitting bolts. Can anyone think of the applications for drilling?

Engine blocks and tool bodies!

Exactly! Remember, ‘DRA’ for Drilling, Reaming, and Applications helps keep this process into perspective.

Milling Techniques

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's discuss milling. In milling, a rotary multipoint cutter works on a stationary workpiece. What do you think makes milling versatile?

Is it the ability to create different shapes and slots?

Absolutely! Milling can produce flat surfaces, slots, and more complex contours. Can anyone name the types of milling?

Peripheral and face milling?

Well done! Remember ‘FC’ for Face and Peripheral Milling. Any questions on milling?

Grinding and Finishing Processes

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next is grinding, which uses abrasive wheels to refine surface finishes. Why do you think grinding is essential?

To achieve precise dimensions?

Exactly! It produces smooth finishes on hard materials. Now, what about finishing processes like lapping and honing?

They're used to improve surface quality?

Correct! To remember, think ‘GFL’ for Grinding, Finishing, and Lapping. Any final questions?

Cutting Tools and Materials

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let’s talk about cutting tools. We have single-point and multi-point tools. What are some materials used for these tools?

High-Speed Steel and Carbide?

Right again! HSS is good for general use, while carbide is for tougher materials. What factors decide the selection of tools?

Workpiece material and cutting speed?

Exactly! Remember ‘CW’ for Cutting speed and Workpiece material that dictate tool choice. Any closing thoughts?

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Material removal processes are essential in manufacturing components that demand precision and fine finishes. This section discusses specific processes such as turning, drilling, milling, and grinding, alongside their respective tools, applications, and performance measures like material removal rate and surface finish.

Detailed

Detailed Summary

Material removal processes, commonly referred to as machining processes, are pivotal in the manufacturing sector for producing components that require precise dimensions and surface quality. This section outlines various common machining processes:

- Turning: Involves a rotating workpiece being shaped by a single-point cutting tool using a lathe. Key operations include facing, straight turning, taper turning, and threading, with applications in creating shafts and cylindrical parts.

- Drilling: Utilizes multi-point tools, typically drill bits, to create round holes. This process extends to various types such as reaming and tapping and is crucial in applications like engine blocks.

- Milling: Involves a stationary workpiece being shaped by a rotating multi-point cutter using a milling machine. Types include peripheral and face milling, with applications for slotting and creating complex contours.

- Grinding: Removes fine material through abrasive wheels, achieving very precise dimensions and surface finishes, particularly on hard materials.

- Finishing Process: Includes methods such as lapping and honing, which aim to enhance the surface quality of machined parts, achieving ultra-smooth finishes necessary in high-performance applications.

The selection of appropriate tools and techniques relies on various factors like workpiece material, desired finish, and operational efficiency, ensuring high-quality outputs across industries from automotive to aerospace.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Turning

Chapter 1 of 1

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

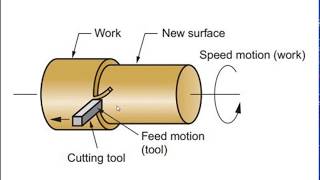

Turning

Description: A workpiece rotates while a single-point cutting tool removes material.

Machine: Lathe

Operations: Facing, straight turning, taper turning, threading.

Applications: Shafts, rods, disc-type components.

Detailed Explanation

Examples & Analogies

Key Concepts

-

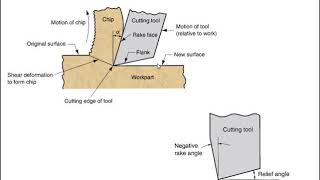

Machining Processes: Techniques to remove material from a workpiece to achieve desired shapes and finishes.

-

Cutting Tools: Tools that remove material; can be single-point or multi-point depending on the process.

-

Surface Finish: The quality of the surface achieved after machining, affecting performance and wear.

-

Dimensional Accuracy: The precision of the dimensions of the machined component.

-

Machinability: The measure of how easily a material can be worked with during machining.

Examples & Applications

Turning is commonly used for producing cylindrical shafts, where uniform shape and finish are critical.

Drilling is employed to create precise bolt holes in engine blocks, which are vital for assembly.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

When cutting and turning, keep the lathe in mind, for perfect shapes and surfaces, it's the best you'll find.

Stories

Imagine a lathe as a spinning dance floor where metal twirls and cuts to shape, perfectly fitting for shafts and tools crafted with escape.

Memory Tools

‘DMPL’ helps remember Drilling, Milling, turning, and grinding in machining.

Acronyms

For surface finish remember ‘RAP’ for Roughness, Accuracy, and Precision.

Flash Cards

Glossary

- Turning

A machining process where a workpiece rotates while a single-point cutting tool removes material.

- Drilling

A process of creating holes in a workpiece using a rotating multi-point cutting tool.

- Milling

A machining process where a rotary cutter removes material from a stationary workpiece.

- Grinding

A finishing process that uses rotating abrasive wheels to remove fine material and achieve smooth surfaces.

- Machinability

The ease with which a material can be machined to the desired quality and tool life.

Reference links

Supplementary resources to enhance your learning experience.