Actuation Mechanisms in MEMS

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Electrostatic Actuation

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're diving into electrostatic actuation, which is widely used in MEMS due to its compatibility with CMOS processes. Can anyone tell me how force is generated in this mechanism?

Is it because of charged electrodes?

Exactly! Electrostatic force results from the interaction between charged electrodes. This allows for fast movements. Can anyone list an application of this mechanism?

Micromirrors can be one application.

Great example! Micromirrors are crucial in optical switching applications. Remember the acronym 'FAST' for Electrostatic Actuation: Fast response, Affordable, Small size, and low Power consumption.

What are the challenges with this mechanism?

Good question! The main challenges include a limited force output and the risk of pull-in instability. In which scenarios do you think those challenges would affect performance?

When high precision is required, it could be a problem.

Exactly! Precision applications need to consider these limitations. In summary, electrostatic actuation is swift and efficient but comes with challenges like limited force and stability issues.

Thermal Actuation

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s move on to thermal actuation. Who can explain how it creates movement?

I think it uses heating to cause expansion or contraction.

Correct! Differential thermal expansion in bimaterial structures is the key principle. What are some applications where you think thermal actuation is used?

It can be used in microgrippers.

That’s right! Microgrippers utilize thermal actuation to grasp small objects. Let's use the mnemonic 'HEAT' — Heating Equals Actuation Temperature — to remember how this mechanism works.

What’s the downside of this mechanism?

Good question! The primary challenges include high power consumption and a slower response time compared to electrostatic actuation. Can anyone think of situations where that might be an issue?

If you need quick actions, that would be a problem.

Exactly! Quick responses are essential in many applications. In summary, thermal actuation is effective but can be slower and use more power.

Piezoelectric Actuation

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, who can tell me about piezoelectric actuation?

It creates motion by applying voltage to specific materials.

Exactly! The shape change in piezoelectric materials upon applying an electric field is fundamental. Who can list a common application for piezoelectric actuators?

Micro-pumps are a good example.

Great! Piezoelectric actuation is widely used in micro-pumping applications. Let’s remember the acronym 'PRECISION': Piezoelectric Requires Electric Current, Increasing Shape, Instigates Oscillation in Nature. What challenges do you think are associated with this mechanism?

High voltage requirements can be an issue.

Correct! It requires higher voltages and thus can be subject to material fatigue over time. So, piezoelectric actuation is precise and fast but requires careful power considerations.

Magnetic Actuation

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let's explore magnetic actuation. How do you think this mechanism generates motion?

It uses current and magnetic fields?

Exactly! By utilizing the Lorentz force resulting from current flow in a magnetic field, it can create significant motion. What kinds of MEMS applications could benefit from this?

Micro-relays could use this mechanism.

Right! Micro-relays and some forms of micro-robots use magnetic actuation effectively. Let’s remember the mnemonic 'MAGNETIC' — Motion Achieved through Generating Net Electromagnetic Tension In Coils. What challenges do you think come with this mechanism?

Complex fabrication sounds like a challenge.

Exactly! It requires complex materials and coils. In summary, magnetic actuation can generate strong forces but has challenges in fabrication and design.

Shape Memory Alloy (SMA) Actuation

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let’s discuss shape memory alloy actuation. Who can explain how it works?

It goes back to its original shape when heated?

That's correct! These materials can return to their original shape upon thermal activation after deformation. What are some applications?

Deployable microstructures and biomedical implants could use this.

Fantastic! To remember this, use the acronym 'SHAPE': SMAs Heat And Produce Elasticity. What do you think the limitations of this mechanism are?

Speed and fatigue could be issues.

Exactly! While they can provide large displacements, the speed can be limited, and material fatigue is a concern. In summary, SMA actuation has unique properties beneficial for specific applications.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section details various MEMS actuation mechanisms including electrostatic, thermal, piezoelectric, magnetic, and shape memory alloy actuation, their principles, applications, advantages, and challenges. Each mechanism showcases a unique approach to converting electrical energy into mechanical motion, enabling MEMS devices to interact dynamically with their environment.

Detailed

Actuation Mechanisms in MEMS

Actuators are crucial components in MEMS (Micro-Electro-Mechanical Systems) that convert electrical signals into mechanical motion, allowing these devices to perform a variety of functions such as movement, force generation, and interaction with the environment. MEMS actuators are designed to be miniaturized while providing rapid and precise movements. This section covers several prominent actuation mechanisms used in MEMS:

1. Electrostatic Actuation

- Principle: Generates electrostatic force between charged electrodes.

- Applications: Commonly seen in micromirrors, RF MEMS switches, and resonators.

- Advantages: Fast response and low power consumption.

- Challenges: Limited force output and the phenomena of pull-in instability.

2. Thermal Actuation

- Principle: Works based on differential thermal expansion in bimaterial structures that create displacement when heated.

- Applications: Used for microgrippers and optical shutters.

- Advantages: Simple structure.

- Challenges: High power consumption and slower response time.

3. Piezoelectric Actuation

- Principle: Involves mechanical deformation of certain materials (like piezoelectric ceramics) when an electric field is applied, causing shape changes.

- Applications: Used in micro-pumps and precision actuators.

- Advantages: Offers high precision and fast response.

- Challenges: Requires high voltages and experiences material fatigue over time.

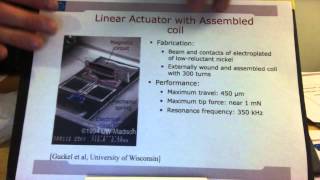

4. Magnetic Actuation

- Principle: Utilizes Lorentz forces, created when current flows through a conductor which is exposed to a magnetic field.

- Applications: Found in micro-relays and micro-robots.

- Advantages: Capable of generating larger forces.

- Challenges: Involves the use of magnetic materials and coils, leading to complex fabrication processes.

5. Shape Memory Alloy (SMA) Actuation

- Principle: Utilizes materials that can 'remember' their original shape; upon heating, they revert to that shape after being deformed.

- Applications: Applicable in deployable microstructures and biomedical implants.

- Advantages: Allows for large displacements.

- Challenges: Limited speed and issues with material fatigue.

Conclusion

The integration of these actuation mechanisms allows MEMS devices to perform sophisticated tasks with efficiency and precision, crucial for modern applications such as robotics, healthcare devices, and consumer electronics.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Overview of Actuation in MEMS

Chapter 1 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Actuators convert electrical signals into mechanical motion or other physical effects. MEMS actuators are miniaturized but capable of precise and rapid movement, enabling dynamic interaction with their environment.

Detailed Explanation

In the context of MEMS (Micro-Electro-Mechanical Systems), actuators are special components that take electrical signals and transform them into physical actions, like moving or applying force. These actuators are incredibly small, which allows them to operate in very tiny spaces while still being highly precise. This precision is essential because it enables MEMS devices to interact effectively with their surroundings.

Examples & Analogies

Think of MEMS actuators like tiny robot arms. Just as a robot arm performs tasks like picking up objects by converting electrical commands into movements, MEMS actuators do the same but on a much smaller scale, allowing them to perform precise operations in devices such as smartphones or medical instruments.

Electrostatic Actuation

Chapter 2 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The most common mechanism due to compatibility with CMOS processes.

● Principle: Electrostatic force is generated between charged electrodes.

● Applications:

● Micromirrors in optical switches

● RF MEMS switches

● Resonators

Advantages: Fast response, low power

Challenges: Limited force output, pull-in instability

Detailed Explanation

Electrostatic actuation is a widely used mechanism in MEMS because it easily integrates with CMOS technology, which is used in most electronic devices. This mechanism functions by generating an electrostatic force when two charged electrodes come close together. The main benefits of electrostatic actuators are that they respond very quickly and consume low amounts of power. However, they do have some limitations, such as not being able to generate a lot of force and facing issues like pull-in instability where the actuator can become stuck.

Examples & Analogies

Imagine pressing a button on your smartphone. The button only pushes down with a light tap, but it registers your action instantly without needing much energy. Electrostatic actuators work in a similar way, responding quickly to electrical signals but with limitations on how hard they can push or pull.

Thermal Actuation

Chapter 3 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Uses heat to create expansion and generate movement.

● Principle: Differential thermal expansion in bimaterial structures produces displacement.

● Applications:

● Microgrippers

● Optical shutters

Advantages: Simple structure

Challenges: High power consumption, slower response time

Detailed Explanation

Thermal actuation involves heating materials to create movement. This technique works because different materials expand at different rates when heated (known as differential thermal expansion). By combining two different materials, a bimaterial structure can bend or twist when heated, leading to displacement, or movement. While the simplicity of the structure is an advantage, thermal actuators generally consume more power and respond more slowly compared to other types.

Examples & Analogies

Think of how a metal spoon bends if you heat one end while keeping the other cool—when one side expands more than the other, it causes a bending motion. Similarly, thermal actuators use heat to create controlled bending movements.

Piezoelectric Actuation

Chapter 4 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Involves mechanical deformation from applied voltage.

● Principle: Electric field causes shape change in piezoelectric material.

● Applications:

● Micro-pumps

● Precision actuators

Advantages: High precision, fast response

Challenges: Requires high voltages, material fatigue

Detailed Explanation

Piezoelectric actuation relies on materials that change shape when an electrical voltage is applied. This principle can convert electrical energy directly into mechanical movement, allowing for very precise control over movement. While these actuators can respond quickly and maintain high accuracy, they typically require high voltage levels to operate, and the materials may degrade over time due to repeated use.

Examples & Analogies

Consider how some speakers work. They convert electrical signals into sound through diaphragm vibrations. A similar effect occurs in piezoelectric actuators, where the application of voltage leads to precise movements, like making tiny pumps or actuators work.

Magnetic Actuation

Chapter 5 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Utilizes Lorentz forces or magnetic attraction/repulsion.

● Principle: Current through a conductor in a magnetic field creates force.

● Applications:

● Micro-relays

● Micro-robots

Advantages: Generates larger forces

Challenges: Requires magnetic materials and coils, complex fabrication

Detailed Explanation

Magnetic actuation works by using the relationship between electricity and magnetism. When an electrical current flows through a conductor placed in a magnetic field, it generates a force (known as the Lorentz force). This type of actuation can produce larger forces compared to other methods, making it suitable for applications like micro-relays and robotic movements. However, using magnetic materials and creating coils can complicate the manufacturing process.

Examples & Analogies

Think of a train being propelled by magnetic forces in a magnetic levitation (maglev) system. The magnets create a powerful push that moves the train forward. Similarly, magnetic actuators use electric currents and magnetic fields to create movements in devices.

Shape Memory Alloy (SMA) Actuation

Chapter 6 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Uses materials that "remember" their original shape after deformation.

● Principle: Thermal activation returns the alloy to its original shape.

● Applications:

● Deployable microstructures

● Biomedical implants

Advantages: Large displacements

Challenges: Limited speed, fatigue issues

Detailed Explanation

Shape Memory Alloy (SMA) actuation relies on special materials that can change shape when heated. When you cool these materials after deforming them, they stay in that new shape until they are heated again, at which point they 'remember' their original shape and return to it. This unique property allows for large movements; however, SMAs can be slow to respond and may wear out after repeated use.

Examples & Analogies

Imagine a rubber band that's been stretched and then frozen; it stays stretched even when cold. Now, picture that rubber band warmed up and instantly snapping back into its original form. This is similar to how shape memory alloys work—returning to their original shape when heated.

Key Concepts

-

Electrostatic Actuation: A key mechanism for rapid and low-power motion in MEMS.

-

Thermal Actuation: Effective yet power-intensive, suitable for slower applications.

-

Piezoelectric Actuation: Offers high precision and quick responses but requires high voltage.

-

Magnetic Actuation: Delivers larger forces, with complex fabrication requirements.

-

Shape Memory Alloy Actuation: Unique thermal responsiveness with large displacements.

Examples & Applications

Micromirrors in optical switches demonstrate electrostatic actuation by adjusting their angle rapidly.

Microgrippers using thermal actuation can grasp and manipulate small items efficiently.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Electrostatic's fast and light, moving quickly, just feels right.

Stories

Imagine a piezoelectric material that stretches and shrinks like a rubber band whenever an electric charge is applied, quickly moving things without a second thought.

Memory Tools

For thermal actuation, remember: HEAT - Heating Enhances Actuated Tension.

Acronyms

'SHAPE' stands for

Shape Heat Activates Production Elasticity for shape memory alloys.

Flash Cards

Glossary

- Electrostatic Actuation

A mechanism that creates motion through the electrostatic force generated between charged electrodes.

- Thermal Actuation

An actuation method relying on thermal expansion and contraction of materials to produce movement.

- Piezoelectric Actuation

A process where piezoelectric materials deform when an electric field is applied, resulting in mechanical movement.

- Magnetic Actuation

Utilizes Lorentz forces produced by current in the presence of magnetic fields to effectuate motion.

- Shape Memory Alloy (SMA)

Materials that return to a predefined shape upon heating after being deformed.

Reference links

Supplementary resources to enhance your learning experience.