Applications in Predictive Maintenance

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Predictive Maintenance

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Welcome everyone! Today we're diving into predictive maintenance, or PdM, in civil engineering. Can anyone tell me what they think predictive maintenance means?

Isn't it about predicting when equipment will fail so we can fix it before something bad happens?

Exactly! Predictive maintenance leverages real-time data and past patterns to foresee equipment failures. This is different from preventive maintenance, which is based on schedules.

What kind of data do we use for this?

Great question! We gather condition monitoring data through various sensors like vibration and temperature sensors. Remember the acronym 'CDAT' for Condition Monitoring, Data Analytics, and Timing in maintenance.

How does data analytics actually work?

Data analytics applies machine learning to spot trends or anomalies in the data collected, which helps us estimate the Remaining Useful Life, or RUL, of the equipment. Can anyone summarize what we've discussed so far?

Predictive maintenance involves real-time data, sensors, and data analytics to prevent failures, and we can remember it as 'CDAT'!

Excellent summary! Let’s keep this in mind as we explore robotics in predictive maintenance.

Robotics in Predictive Maintenance

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's discuss the role of robotics in predictive maintenance. Why do you think robotics are important for maintenance tasks?

They can access hard-to-reach places, right?

Precisely! For instance, aerial drones can inspect tall structures like bridges, and crawling robots can detect issues in pipelines. We call these inspection robots.

What about underwater inspections?

Great example! Underwater robots, also known as ROVs, inspect submerged structures. Remember, these robots significantly reduce the risk for human workers in dangerous environments.

How do they actually detect problems?

They are equipped with advanced sensors. For example, LiDAR and thermal cameras help map structural integrity. Can anyone explain why this continuous monitoring is advantageous?

It helps in catching issues early, which prevents bigger problems later.

Correct! Proactive monitoring leads to safer and more cost-efficient maintenance. Remember this as we move into sensors and IoT in predictive maintenance.

Sensors and IoT in Predictive Maintenance

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s discuss sensors. Why do you think they are essential in predictive maintenance?

They collect the real-time data we need to know what's going on with the machines.

Exactly! We use various sensors such as vibration sensors to detect misalignments, temperature sensors to monitor overheating, and even strain gauges for structural deformation. Can anyone name a few types of sensors?

Vibration, temperature, and strain gauges!

Perfect! Additionally, IoT allows these sensors to communicate with each other, forming a wireless sensor network for comprehensive monitoring. Why might you think this is important?

It provides a real-time overview and reduces the need for humans to go into risky environments.

Absolutely! Real-time data transmission is key to implementing effective predictive maintenance strategies. Let's wrap up with exploring data processing next.

Data Acquisition and Processing Techniques

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Moving on to data acquisition and processing, why is it crucial for predictive maintenance?

Without processing the data, we wouldn't have any useful insights.

Exactly! Techniques like signal processing using Fast Fourier Transform (FFT) help identify anomalies. Have any of you heard of this before?

I've seen it mentioned in signal processing classes!

Great! It translates data from the time domain to frequency domain – very useful for detecting issues. Can anyone share an example of machine learning applications in PdM?

I think supervised learning could help us predict when a machine might fail based on past data.

Spot on! Supervised learning uses labeled data to train models for prediction. This is an essential aspect of predictive maintenance. Let’s summarize today's points before closing.

We’ve covered the importance of data acquisition, types of processing, and machine learning applications in predictive maintenance. Who has a key takeaway?

Data is essential for insightful analysis in maintenance decisions!

Exactly! Keep this in mind as we move towards discussing predictive maintenance for civil infrastructure.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section explores how predictive maintenance utilizes real-time data and smart technology to monitor infrastructure health, predicting failures before they occur. Key concepts include condition monitoring, robotics in maintenance, sensor applications, and the integration with Building Information Modeling (BIM). The advantages, challenges, and future trends of predictive maintenance in civil engineering are also highlighted.

Detailed

In today's Industry 4.0 landscape, predictive maintenance (PdM) represents a significant advancement in ensuring the reliability and safety of civil engineering infrastructure. By employing real-time data collection through various sensors, along with robotics and advanced analytics, predictive maintenance allows engineers to foretell potential failures in infrastructure like bridges and buildings. This section delves into the core components of predictive maintenance, defining terms such as condition monitoring, data analytics, and failure prediction. Robotics plays a vital role in inspecting and maintaining hard-to-reach or hazardous areas of infrastructure. Various sensor types help in data acquisition, while machine learning techniques further analyze this information to enhance maintenance strategies. The section also emphasizes the integration of predictive maintenance with BIM, streamlining operations and facilitating proactive measures. Although predictive maintenance poses significant advantages, it also faces challenges such as high initial costs and the need for skilled professionals. The future of predictive maintenance is poised for growth with trends such as autonomous decision-making robots and self-healing systems.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to Predictive Maintenance

Chapter 1 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

In the era of Industry 4.0, predictive maintenance (PdM) has emerged as a transformative strategy that leverages robotics, automation, and data analytics to predict equipment failures before they occur. In Civil Engineering, where infrastructure health and machinery reliability are paramount, predictive maintenance ensures operational efficiency, safety, and cost-effectiveness. Through robotics and advanced sensor networks, engineers can now continuously monitor civil infrastructure like bridges, buildings, tunnels, and equipment such as pumps, cranes, and mixers—leading to proactive decisions that prevent failures and optimize performance.

Detailed Explanation

Predictive maintenance, often labeled as PdM, is an innovative approach that utilizes advanced technology to preemptively identify potential equipment failures. In the context of Civil Engineering, it becomes crucial as the safety and functionality of structures depend heavily on their maintenance. By employing robotics and sensors, engineers can monitor various infrastructure elements in real-time, allowing them to act on signs of wear and tear before failures occur. This preemptive strategy not only enhances safety by mitigating risks but also leads to financial savings by avoiding emergency repairs and optimizing maintenance schedules.

Examples & Analogies

Think of predictive maintenance like a doctor performing routine check-ups on patients. Just as a doctor uses various tests to gauge health and ensure no underlying issues are present, predictive maintenance uses sensors and data to assess the health of machinery and infrastructure before any symptoms of failure appear.

Fundamentals of Predictive Maintenance

Chapter 2 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

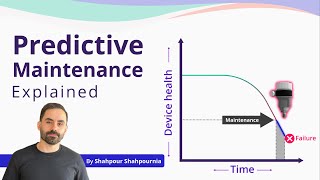

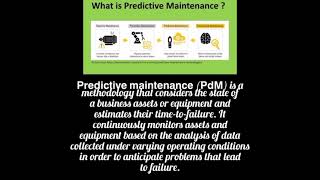

Predictive Maintenance refers to the use of real-time data and historical patterns to anticipate failures or degradation in mechanical systems before they occur. Unlike reactive maintenance (after failure) or preventive maintenance (based on time schedules), PdM focuses on the actual condition of the system using smart technology.

Key Concepts:

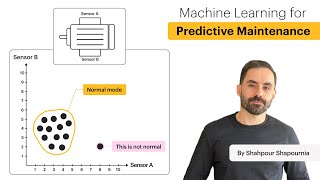

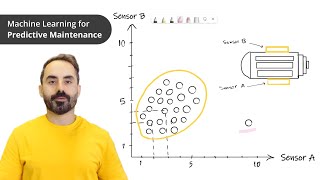

- Condition Monitoring: Gathering real-time data from sensors (vibration, temperature, acoustic, etc.).

- Data Analytics: Applying machine learning algorithms to detect trends or anomalies.

- Failure Prediction: Estimating Remaining Useful Life (RUL) of components.

- Automated Scheduling: Generating work orders for maintenance before the breakdown occurs.

Detailed Explanation

The core of predictive maintenance involves using current and past data to foresee potential failures in equipment or structures before they actually happen. This approach diverges from traditional methods that wait until a problem manifests (reactive maintenance) or follows a set schedule regardless of actual need (preventive maintenance). Key components include condition monitoring, which involves using sensors to track the real-time status of equipment; data analytics, where machine learning assists in identifying patterns or anomalies; failure prediction, which estimates how much longer a component can function effectively; and automated scheduling, which prompts maintenance activities based on predicted statuses rather than arbitrary timelines.

Examples & Analogies

Imagine a car with a smart maintenance system that tracks its performance metrics like oil levels, tire pressure, and engine temperature. Instead of waiting until the car breaks down or changing the oil every 3,000 miles regardless of condition, it uses real data to determine when maintenance is truly needed, thus extending the car's life and enhancing its reliability.

Role of Robotics in Predictive Maintenance

Chapter 3 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Robotics is central to implementing predictive maintenance, especially in environments that are hazardous, difficult to access, or require high precision.

Inspection Robots:

- Aerial Drones: Used to inspect tall structures like towers, chimneys, and bridges.

- Crawling Robots: Climb on steel frameworks or pipelines to detect corrosion or cracks.

- Underwater Robots (ROVs): Inspect submerged structures like piers, docks, or dams.

Detailed Explanation

Robots play a crucial role in predicting maintenance needs in challenging environments. For instance, aerial drones can easily inspect high-rise structures from above, while crawling robots are designed to navigate along complex surfaces to detect any signs of damage, such as corrosion or cracks. Underwater robotics are essential for the inspection of submerged structures, a task that would be perilous or impossible for human divers. This utilization of robotics greatly enhances the ability to monitor infrastructure health accurately without putting human lives at risk.

Examples & Analogies

Think of inspection robots as the 'sherpas' of infrastructure monitoring. Just like sherpas expertly navigate treacherous mountains to ensure climbers' safety with minimal risk, these robots traverse challenging environments, allowing engineers to gather vital health information about infrastructure without risking their own safety.

Sensors and IoT in Predictive Maintenance

Chapter 4 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Sensors and IoT (Internet of Things) form the backbone of condition monitoring. These devices collect data that is processed either on-edge or through cloud platforms.

Types of Sensors Used:

- Vibration Sensors: Detect misalignments and imbalances in rotating machines.

- Temperature Sensors: Identify overheating in electrical or mechanical systems.

- Strain Gauges: Measure deformation in structural components.

- Acoustic Emission Sensors: Detect early signs of material fatigue or crack propagation.

- Humidity and Moisture Sensors: Monitor environmental degradation factors for concrete or steel.

Detailed Explanation

The efficacy of predictive maintenance largely relies on advanced sensors and the Internet of Things (IoT) technologies. These sensors are capable of monitoring various physical phenomena, such as vibrations, temperatures, and strains. By analyzing the data collected by these sensors, engineers can identify irregularities that may indicate problems, allowing for timely interventions. This monitoring is often done through cloud platforms, which provides the advantage of real-time data access and analysis capabilities from virtually anywhere.

Examples & Analogies

Consider the various sensors in a smart home. Just as motion sensors trigger security alerts and temperature sensors regulate heating systems, various sensors in predictive maintenance monitor the health of infrastructure. They allow for the immediate detection of changes, much like how a smart device ensures your home environment is always optimal.

Data Acquisition and Processing Techniques

Chapter 5 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Raw data collected from sensors must be processed for meaningful insights.

Signal Processing:

- FFT (Fast Fourier Transform): Converts time-domain data to frequency domain to identify anomalies.

- Wavelet Analysis: Useful for non-stationary signals like impact forces.

- Filtering Techniques: Eliminate noise and improve accuracy.

Detailed Explanation

After raw data is gathered from various sensors, it needs to be refined and processed to extract meaningful insights. This involves techniques such as signal processing, which includes converting data from one format to another to identify specific trends or anomalies. For example, Fast Fourier Transform (FFT) helps shift data into a frequency form, making it easier to spot irregularities. Other methods like wavelet analysis and filtering help improve the accuracy of readings by removing noise and focusing on relevant data.

Examples & Analogies

Think of data processing like sorting through a messy drawer. Just as you would filter through clutter to find useful items, data processing involves organizing raw data to highlight valuable insights, which are then used for effective decision-making.

Advantages and Challenges of Predictive Maintenance

Chapter 6 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Advantages:

- Reduces unplanned downtime.

- Increases safety of civil structures.

- Extends equipment and structure life.

- Optimizes maintenance budgets.

Challenges:

- High initial investment in robotics and sensors.

- Need for skilled professionals in AI, ML, and automation.

- Data overload and management issues.

- Integration complexities with legacy systems.

Detailed Explanation

Implementing predictive maintenance offers numerous advantages, including reduced unexpected breakdowns, improved safety, extended lifespan of machinery, and more efficient budgeting for maintenance activities. However, it’s not without challenges. The initial costs for robotics and sensor technology can be daunting, and the need for skilled professionals in areas like AI and machine learning can further complicate its adoption. Additionally, managing large volumes of data and integrating new systems with existing infrastructure presents notable hurdles.

Examples & Analogies

Consider predictive maintenance like adopting new technology in personal life, such as a new smart home system. The initial setup costs and learning curve can be challenging, but the long-term benefits of enhanced security, energy savings, and ease of use often outweigh those challenges.

Key Concepts

-

Predictive Maintenance: A proactive approach to maintenance based on real-time data analysis.

-

Condition Monitoring: Continuous monitoring of equipment condition using sensors.

-

Robotics Role: The implementation of robots for safe and efficient inspection work.

-

Data Analytics: The use of machine learning for analyzing real-time and historical data.

-

Wireless Sensor Networks: Communication networks allowing real-time data sharing across extensive areas.

Examples & Applications

Using drones to inspect bridges, reducing the time needed for inspections and improving safety outcomes.

Implementing vibration sensors in heavy machinery to detect misalignments and prevent serious malfunctions.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

In maintenance we must predict, to avoid equipment's sudden conflict.

Stories

Once there was an engineer who used sensors to feel the pulse of bridges; he could predict their needs just like a doctor, ensuring they were safe and healthy.

Memory Tools

Use 'PRISM'—Predict, Real-time, Inspect, Schedule, Maintain—to remember the steps in predictive maintenance.

Acronyms

CDAT

Condition Monitoring

Data Analytics

Timing.

Flash Cards

Glossary

- Predictive Maintenance (PdM)

A strategy utilizing real-time data and analytics to anticipate equipment failures before they occur.

- Condition Monitoring

The process of collecting real-time data from sensors to monitor the condition of equipment.

- Remaining Useful Life (RUL)

An estimate of how long a piece of equipment will continue to function properly before it fails.

- Robotic Inspection

The use of robotic technology for inspecting hard-to-reach areas of infrastructure.

- Wireless Sensor Networks (WSNs)

Sensor networks that allow for real-time data transmission over large areas.

Reference links

Supplementary resources to enhance your learning experience.