Definition

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Shear Center

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Welcome, everyone! Today, we will be discussing the shear center, which is defined as the point where the net torque from shear stress distributions due to transverse loads equals zero. Can anyone tell me why this concept is important?

Does it help in understanding how beams twist under load?

Exactly! If we can identify the shear center, we can ensure loads are applied correctly to avoid unwanted twisting.

Are there specific shapes for which we can find the shear center easily?

Good question! We can derive the shear center for thin and open cross-sections. This is an essential point that will help us in structural design.

Will we look at examples of those cross-sections?

Yes, we'll explore those as we go along! Remember, if a transverse load acts outside the shear center, it can lead to twisting. We'll cover that next!

Deriving Location of Shear Center

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now that we understand what the shear center is, let’s discuss how we can find its location. For thin and open cross-sections, we need to derive specific formulas.

What is the starting point for this derivation?

We start with the shear stress distribution and consider the total torque about a point. Can someone recall the expression for torque in this context?

It's the integral of shear stress times the distance from the shear center, right?

Exactly! And once we equate this to zero, we can derive the coordinates of the shear center.

So if the torque about the shear center is zero, it minimizes twisting?

Yes! That’s precisely the point. Knowing this will help guide us in practical applications.

Bending and Twisting Relationships

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let’s talk about what happens when loads do not apply through the shear center. Can anyone explain this scenario?

The beam can twist because the torque about the shear center will not be zero.

Right again! This can lead to bending twisting in distorted forms. Applying the load through the shear center is crucial. Otherwise, inefficiencies can occur.

What types of cross-sections are more prone to this problem?

Asymmetrical cross-sections are more susceptible. We’ll investigate specific examples of these cross-sections in detail next.

Symmetrical vs. Unsymmetrical Cross-sections

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s analyze symmetrical versus unsymmetrical cross-sections. Do students remember what we defined about their shear centers?

For symmetrical cross-sections, the shear center lies along the line of symmetry.

Exactly! And as for unsymmetrical cross-sections, we have to find the shear center position through calculations. Who can cite examples?

L-shaped cross-sections are one type of unsymmetrical cross-section!

Correct! Understanding these differences helps engineers prevent twisting in real applications.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

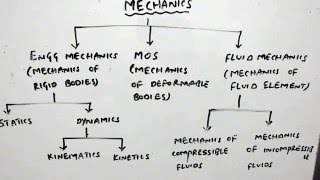

Standard

In this section, we explore the definition of the shear center, highlighting its significance in determining where to apply transverse loads without inducing unwarranted twisting in beams. We also discuss the derivation of the shear center for specific cross-sectional shapes and its importance in structural analysis.

Detailed

Detailed Summary

The shear center is crucial in structural mechanics, defined as the point in the cross-sectional plane where the net torque generated by shear stress distributions, originated from transverse loads, is zero. This point is significant when designing structural elements, as its location determines the behavior of the element under load. The challenge arises in finding analytical formulas for the shear center for general cross-sections; however, derivations can be achieved for thin and open cross-sections. This section provides insights into the calculations surrounding the shear center, discusses various structural implications, and reinforces the concept's relevance in preventing twisting and ensuring structural integrity under transverse loads.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Definition of Shear Center

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

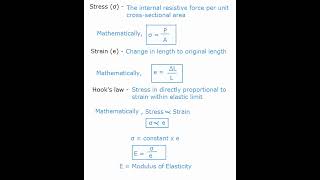

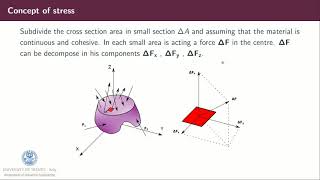

The shear center is defined as the point in the cross-sectional plane relative to which the net torque due to shear stress distribution (originating because of transverse load only) vanishes.

Detailed Explanation

The shear center is a critical concept in structural mechanics, particularly when analyzing beams under transverse loads. It is the point where the application of shear force does not cause any twisting in the beam. Essentially, if you were to place the load at the shear center, the beam would solely bend without having any additional rotational motion. This concept is essential for engineers to consider when designing and analyzing structural components to ensure they maintain their intended shape and functionality under load.

Examples & Analogies

Think of the shear center like the balancing point of a seesaw. If you sit exactly at the center, it will go up and down without tipping sideways. If you sit too far to one side, not only will it tilt, but it will also create a rotational motion. Just like in a seesaw, the shear center is where forces can be applied without causing twisting effects, allowing the structure to behave predictively.

Finding the Shear Center

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

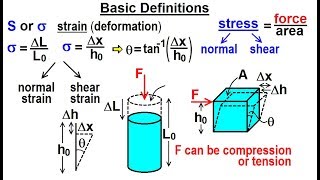

Finding analytical formula for the location of the shear center for a general cross-section isn’t possible. However, the same can be derived for thin and open cross-sections such as the one in Figure 1.

Detailed Explanation

For complex cross-sections, deriving a formula for the shear center is often impractical. However, for simpler geometries, like thin and open cross-sections, there are methods to ascertain its position. In practice, engineers often utilize graphical methods or computational tools to find the shear center for more complex shapes. This highlights the importance of understanding the principles behind shear centers, even if computational tools are used to find their exact locations.

Examples & Analogies

Imagine trying to find the balance point of a weirdly shaped piece of wood. It’s much easier to find the balance point on a flat piece of cardboard than on a jagged rock. In engineering, many designs can be approximated as simple shapes like that cardboard, allowing for easier calculations, while more complex shapes might need extra tools, like a balance scale or computer software.

Torque and Shear Stress Distribution

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

As the net torque about the shear center must be zero, we can first find the total moment about the shear center and then equate its x-component to zero.

Detailed Explanation

In the context of shear centers, it's key to remember that for stability, the sum of forces and torques acting on the structure must equal zero. The net torque calculated about the shear center must be balanced; otherwise, the structure will twist. This leads to equations that help in determining the positions of the shear center by setting up the conditions where the torques cancel each other out. Understanding these dynamics is crucial for ensuring the structural integrity of beams.

Examples & Analogies

Think of balancing a spinning top. For it to not fall over, the forces and rotational effects need to be in equilibrium. If a child pushes down on one side at an unequal angle, the top will begin to wobble and potentially fall. Similarly, if the forces on a beam are not balanced around the shear center, it leads to twisting and potential failure.

Importance of Principal Axes

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The formulas for shear center coordinates hold only if y and z axes are also the principal axes of the cross-section.

Detailed Explanation

The principal axes are the axes about which the structure's moments of inertia are maximum or minimum, making them essential for analyzing shear centers. If the shear center formulas only apply when the principal axes coincide with the coordinate axes, it underscores the significant relationships between a shape's geometry and its mechanical properties. Knowing whether you're aligned with the principal axes can drastically simplify calculations and lead to correct applications in structural design.

Examples & Analogies

You can visualize this with a tightrope walker. If they stand straight on the rope (aligned with their center of gravity) versus leaning or swaying (off-axis), their balance will be maintained only when centered. Similarly, for beams and structures, maintaining alignment with principal axes ensures stability under loads, preventing failure.

Key Concepts

-

Shear Center: The location where the net torque due to shear stress distribution is zero.

-

Bending and Twisting Relationship: If load does not apply at the shear center, it may cause the beam to twist.

-

Symmetry in Cross Sections: For symmetrical cross-sections, the shear center is along the line of symmetry.

Examples & Applications

In a T-beam, the shear center is found at the centroid due to symmetry.

For a channel beam, the shear center is not at the centroid because of its unsymmetrical shape, and calculations are needed.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

In a beam that can bend, the shear center is your friend, keep the load in line, and turning's not a sign.

Stories

Imagine a tower where workers load bricks. If placed right at the center, it stands firm; otherwise, it twists, and bricks may fall!

Memory Tools

C-T-L - Center-Twist-Load. Remember to keep your loads at the center to avoid twisting.

Acronyms

S-L-O-T

Shear

Load

Offset

Torque. An acronym to recall the important concepts related to shear center.

Flash Cards

Glossary

- Shear Center

The point in the cross-sectional plane of a structural element where the net torque due to shear stress distribution disappears when transverse loads are applied.

- Torque

A measure of the force that can cause an object to rotate about an axis.

- Transverse Load

A load that is applied perpendicular to the longitudinal axis of a structural element.

- Crosssection

The intersection of a solid and a plane which may yield a two-dimensional shape.

Reference links

Supplementary resources to enhance your learning experience.