Isotropic Materials

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Definition of Isotropic Materials

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we'll begin by discussing isotropic materials. Can anyone tell me what the term 'isotropic' means?

I think it means something has the same properties in every direction.

Exactly! Isotropic materials have uniform properties regardless of the direction. In contrast, anisotropic materials show different properties when stressed in various directions. For instance, wood is anisotropic.

So, isotropic materials don't have directional dependencies?

Correct! That's a critical point. It's significant because we can simplify the stress-strain relationship for isotropic materials.

Stress-Strain Relation

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's dive into the stress-strain relation for isotropic materials. The stiffness tensor is greatly simplified. Can anyone remind me how many independent constants are there for isotropic materials?

Two, right? Lame’s constants?

Yes! Lame’s constants, λ and µ, are all we need. That’s why isotropic materials are easier to characterize compared to anisotropic ones that need more constants.

How do we derive those constants from experiments?

Great question! We can perform a couple of simple experiments to measure stress and strain in different directions.

Experimental Analysis

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's discuss how we can experimentally determine the properties of isotropic materials. Suppose we stretch a beam along one axis. What do you think happens?

The beam will elongate, but the dimensions in the other directions will change too.

Exactly! This behavior illustrates Poisson's ratio. As a result of stretching, we can determine how stress and strain relate, which leads to a clear mathematical framework.

Can we apply the same concept to shear strain and bulk modulus?

Yes, the same principles apply! For shear and volumetric stress, we look into how the volume reacts under pressure, which ties back into the behavior of isotropic materials through bulk modulus.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section explores the unique stress-strain relationship of isotropic materials, deriving Lame’s constants and their implications. Through various experimental setups that demonstrate the consistent properties across different directions, it emphasizes that only two independent constants are needed to describe isotropic materials fully.

Detailed

Isotropic Materials

Isotropic materials are defined by their consistent mechanical properties in all directions, in contrast to anisotropic materials, which exhibit different behaviors when stress is applied in different directions. In this section, we discuss the fundamental stress-strain relation for isotropic materials, which can be described using a simpler relationship than the general case that requires extensive parameters.

Key Concepts:

- Stress-Strain Relation for Isotropic Materials: This relation is defined by two independent constants, Lame’s constants, denoted as λ and µ, which characterize the elasticity of the material.

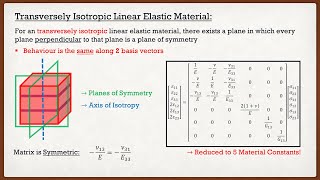

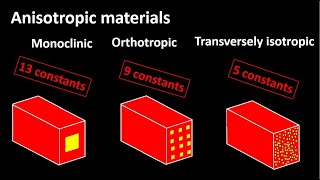

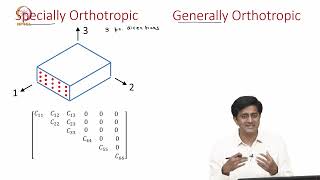

- Mathematical Representations: Through rigorous analysis, we show that if strain is applied in different directions, the generated stress will be the same, resulting in conditions like C1111 = C2222 = C3333, simplifying the stiffness tensor to only require two material constants instead of 21.

- Equations: The equations provided help establish the relation between stress and strain:

- The general form incorporates Lame’s constants, yielding relationships for Young’s modulus (E), Poisson's ratio (ν), and shear modulus (G).

- Important derivations provide key properties whether considering longitudinal strain or volumetric strain.

- Physical Significance: The behavior of isotropic materials under stress leads to observable phenomena such as longitudinal strain affecting lateral strain, encapsulated by Poisson's ratio.

- Material Behavior in Real-World Applications: The understanding of isotropic materials is crucial for applications in engineering where uniform characteristics are desired across structures.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to Isotropic Materials

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Isotropic materials have the same property in every direction. To understand this, consider a body made up of an isotropic material. We stretch the material at an arbitrary point along e direction.

Detailed Explanation

Isotropic materials are defined by their uniformity in properties, meaning that their mechanical response is consistent regardless of the direction of the applied force. For example, when we stretch a piece of rubber equally in any direction, it will behave the same way in terms of deformation, regardless of which direction we stretch it. This uniform property is contrary to anisotropic materials, which display different properties depending on their direction due to their internal structure.

Examples & Analogies

Imagine a perfectly round balloon. No matter how you pull on it (up, down, left, or right), it expands uniformly. This behavior represents isotropic materials. If you had a shaped piece of clay, stretching it in one direction might change its dimensions more significantly in that direction than in others, showing the behavior of an anisotropic material.

Strain and Stress Relations

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The strain matrix at the point of stretching only has ϵ₁₁ as a non-zero component. Using the general form of linear stress-strain relation, we can derive specific equations for isotropic materials.

Detailed Explanation

When an isotropic material is stretched in one direction, the only non-zero strain component will be in that direction, represented as ϵ₁₁. The stress can then be calculated using specific relationships defined for isotropic materials. This relationship allows us to predict the behavior of the material under various stress and strain conditions. Notably, when we perform two experiments stretching the material in different directions but obtaining the same strain, the resulting stresses should also be the same, confirming the isotropic nature of the material.

Examples & Analogies

Think of a sponge. If you squeeze it from the side, it compresses in that direction, but it also expands outwards in a way that maintains its overall shape. If you could measure how much it squeezes and expands, you'd find it behaves consistently no matter how you apply the pressure—this showcases the isotropic behavior.

Lame's Constants and Material Properties

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

When we work out the stress-strain relation using rigorous mathematical derivation, we find that for isotropic materials, we can express mechanical properties using Lame's constants (λ, µ). These define the relationship between stress and strain.

Detailed Explanation

Through mathematical derivation of the stress-strain relationship for isotropic materials, we introduce Lame's constants, λ (Lamé's first parameter) and µ (shear modulus), which significantly simplify how we express the material's mechanical behavior. The constants relate directly to how materials deform under stress, allowing engineers to predict how structures will respond under various forces. This derivation reduces the number of constants we need to know from 21 (for anisotropic materials) to just 2 for isotropic materials.

Examples & Analogies

Consider a rubber band. When you stretch it, you can easily see how far it extends before it snaps. We could measure its 'stretchiness' with just two measurements: how much force you apply and how much it stretches. This is akin to using Lame's constants for an isotropic material.

Physical Significance of E, G, and ν

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The strain in one direction depends not only on the stress component in that direction but also on the stress in other directions. This is related to Young's Modulus (E), Shear Modulus (G), and Poisson's Ratio (ν).

Detailed Explanation

In an isotropic material, when stress is applied in one direction, it induces not only strain in that direction but also affects the dimensions in the perpendicular directions. Young's Modulus (E) measures the stiffness of a material in tension or compression, while Shear Modulus (G) deals with how materials deform under shear stress. Poisson's Ratio (ν) quantifies how much a material compresses laterally when stretched longitudinally. Together, these constants help us understand and predict how materials behave under various load conditions.

Examples & Analogies

Imagine pulling on a long piece of soft dough. As you pull and it stretches (longitudinal strain), you notice that it also gets thinner in the middle (lateral strain). Young's Modulus would define how resistant to stretching the dough is, Shear Modulus how it reacts to any twisting force, and Poisson's Ratio would relate the thinning to the stretching.

Key Concepts

-

Stress-Strain Relation for Isotropic Materials: This relation is defined by two independent constants, Lame’s constants, denoted as λ and µ, which characterize the elasticity of the material.

-

Mathematical Representations: Through rigorous analysis, we show that if strain is applied in different directions, the generated stress will be the same, resulting in conditions like C1111 = C2222 = C3333, simplifying the stiffness tensor to only require two material constants instead of 21.

-

Equations: The equations provided help establish the relation between stress and strain:

-

The general form incorporates Lame’s constants, yielding relationships for Young’s modulus (E), Poisson's ratio (ν), and shear modulus (G).

-

Important derivations provide key properties whether considering longitudinal strain or volumetric strain.

-

Physical Significance: The behavior of isotropic materials under stress leads to observable phenomena such as longitudinal strain affecting lateral strain, encapsulated by Poisson's ratio.

-

Material Behavior in Real-World Applications: The understanding of isotropic materials is crucial for applications in engineering where uniform characteristics are desired across structures.

Examples & Applications

Steel and aluminum are common isotropic materials that demonstrate uniform mechanical properties across various loading directions.

Concrete, although often treated as isotropic for simplicity, behaves differently under tension vs compression in real-world applications.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Isotropic's sound, properties abound, equal in each way, no matter the play.

Stories

Imagine a perfect ball, rolling with ease, it moves the same, no matter the breeze. This represents isotropic material behavior; consistent and stable at every measure.

Memory Tools

I for Isotropic — Imagine Isotropic materials, like Ice cream that doesn’t melt differently regardless of how you look at it.

Acronyms

ISOTROPIC — 'In Simple Order, The Resilience Of Properties Is Consistent.'

Flash Cards

Glossary

- Isotropic Materials

Materials with the same mechanical properties in all directions.

- Anisotropic Materials

Materials with directional dependence in mechanical properties.

- Stress

Force per unit area within materials, often described in terms of tension, compression, and shear.

- Strain

Deformation per unit length of a material under stress.

- Lame's Constants

Two material constants, λ and μ, that describe the elastic properties of isotropic materials.

- Poisson's Ratio

A measure of the transverse strain in a material when it is stretched longitudinally.

- Shear Modulus

Describes how a material deforms under shear stress.

- Bulk Modulus

Describes a material's response to uniform pressure applied in all directions.

Reference links

Supplementary resources to enhance your learning experience.