Introduction

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Understanding Failure in Materials

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's start by discussing what happens when a material is subjected to stress. When we apply traction to a body, it deform—can anyone tell me what kind of deformation we might expect?

It could either yield or buckle, right?

Exactly! Yielding refers to a plastic deformation where the material can't return to its original shape, while buckling is a sudden lateral deflection of the structure. Now, why do you think failure initiates at specific points rather than all at once?

Maybe because different parts experience different levels of stress?

Correct! Each point on the body can have a different state of stress and strain, which leads us to consider how we define failure. This leads to the six theories that guide our understanding.

What are those six theories?

Great question! We'll go over them in detail shortly, but they primarily address variations in principal stress, shear stress, and energy considerations.

And how are these theories practically applied?

They guide engineers in designing to prevent failure in materials under complex loading. We'll explore their applications in our next session.

Theoretical Framework for Failure

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's look into our first theory, the Maximum Principal Stress Theory. Can anyone explain what it involves?

It's about the critical value of the principal stress reaching a point that leads to failure, right?

Exactly! It's derived from tests like simple tension tests. What about the Maximum Shear Stress Theory?

That one focuses on the shear stress reaching critical levels for failure!

Right on! Both these theories help assess materials under different loading conditions. Who can summarize what we've learned about these theories?

Both theories help determine how much stress different materials can handle before failing.

Great! Understanding these principles is vital for ensuring safety in material design.

Energy Considerations in Failure

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now that we've covered stress-based theories, let's discuss the Distortional Energy Theory. What distinguishes it from the others?

It relates to the energy stored at a point, not just strain or stress!

Exactly! This theory considers the changes in shape under load and helps us understand failure due to energy exceeding critical levels. Why do you think this approach is beneficial?

It gives us a comprehensive view of how energy affects material behavior.

Precisely! Being aware of how energy is involved aids in predicting failures more accurately. I look forward to seeing how you apply these theories in your projects!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section explains how an arbitrary body subjected to different types of stress can fail when certain thresholds of stress or strain are exceeded. It introduces six primary theories of failure that depend on the stress state of materials and outlines the basis for each theory.

Detailed

Introduction to Theories of Failure

In solid mechanics, the understanding of how materials fail under applied stresses is crucial for design and safety. This section begins with a conceptual overview of an arbitrary body clamped at certain points, which experiences deformation due to applied traction forces. As these forces increase, the body may ultimately fail, characterized either by yielding or buckling, or by the initiation of cracks. Notably, failure doesn't occur uniformly across the body but initiates at specific points where stress or strain components reach critical values.

The section further elaborates on six primary theories of failure:

1. Maximum Principal Stress Theory

2. Maximum Shear Stress Theory

3. Maximum Normal Strain Theory

4. Maximum Shear Strain Theory

5. Distortional Energy Theory

6. Octahedral Shear Stress Theory

Each theory is derived based on the unique failure mechanisms concerning the stress or strain components within materials, highlighting the need for understanding complex multi-point stress states, as critical values might differ depending on the nature of loading applied to the material.

Youtube Videos

![Mechanics of Solids [Intro Video]](https://img.youtube.com/vi/TdmQGMUbUVw/mqdefault.jpg)

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Overview of Failure in Solid Mechanics

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Think of an arbitrary body clamped at some points on its surface as shown in Figure 1. The body deforms due to the applied traction. As we increase the magnitude of applied traction, the body deforms more and at one point, the body will eventually fail.

Detailed Explanation

In solid mechanics, when a body (like a metal bar) is subjected to forces (traction), it undergoes deformation. As we apply more force, the deformations increase. Eventually, the material can reach a point where it cannot withstand the stress and fails. Failure can mean the material yields (permanently deforms) or buckles (loses stability). It's critical to understand that failure does not occur uniformly across the entire body; rather, it usually starts at specific weak points.

Examples & Analogies

Think of a rubber band: when you stretch it gently, it will return to its original shape. Keep pulling, and eventually, it snaps. The point at which it snaps is similar to the failure point of materials when they are subjected to increasing forces.

Initiation of Failure

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

This failure can be in terms of the body suddenly getting deformed a lot (yielding or buckling) or due to cracks developing in the body. The failure usually initiates at a point in the body and not at all points together (e.g., due to crack).

Detailed Explanation

Failure occurs when specific conditions at some points in a material exceed its limits. For example, if there's an internal flaw or a high-stress concentration at one location, cracks may form there first. This is important because certain points within a structure, like welds or corners, may be more susceptible to failure than others, which is why engineers must carefully analyze these areas.

Examples & Analogies

Consider a glass cup. If you tap it gently on the edge, it may withstand. However, if you keep tapping it on the same spot repeatedly, a crack may develop over time, leading to failure. This demonstrates how localized stress can lead to failure at specific points rather than a uniform failure of the entire object.

State of Stress and Strain

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

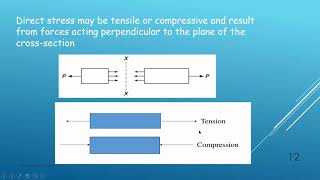

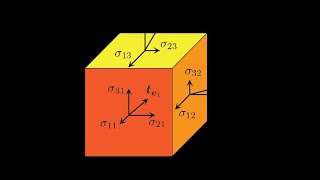

At each point in the body, a different state of stress and strain exists. If, at a point, some function of stress or strain components reaches a critical value, failure occurs.

Detailed Explanation

Each point in a structure experiences unique forces that create specific internal conditions called 'stress' (force per area) and 'strain' (deformation caused by stress). Understanding these states is crucial for predicting where and how failure will occur. If the stress or strain at any point exceeds the material’s critical limits, that point will fail.

Examples & Analogies

Think of bending a metal ruler. If you bend it slightly, it may not show any damage. But if you keep bending it too much, at a certain point (the critical limit), it will permanently deform or break. This illustrates how each point experiences different amounts of stress and how exceeding a critical limit leads to failure.

Theories of Failure

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The different theories of failure have been developed on the basis of the specific form of the failure function in terms of stress/strain components. For example, failure could occur at a point due to principal stress component reaching a critical value or maximum shear stress reaching a critical value.

Detailed Explanation

Engineers use various theories of failure to predict when materials will fail under different forces. These theories consider factors such as maximum stress, shear stress, normal strain, and energy stored in the material. Each theory offers a perspective on when and how a material might fail, based on the type of stresses it experiences.

Examples & Analogies

Imagine cutting a rope with different tools. A knife cuts through the rope (maximum shear stress theory), while a piece of sandpaper wears it down slowly (distortional energy theory). Each cutting method represents different prediction theories for material failure.

Listing the Theories of Failure

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The various theories of failure can be listed as follows:

1. Maximum principal stress theory

2. Maximum shear stress theory

3. Maximum normal strain theory

4. Maximum shear strain theory

5. Distortional energy theory

6. Octahedral shear stress theory

Detailed Explanation

These theories provide frameworks to predict failure based on stress and strain in materials. For instance, the Maximum Principal Stress Theory focuses on the highest normal stress in the material, while the Maximum Shear Stress Theory looks at the most significant shear stress. Understanding these helps engineers select appropriate materials for structures.

Examples & Analogies

Think of these theories as different diagnostic tools for a doctor assessing a patient. Each tool (theory) provides insight into a specific aspect of the patient's (material's) condition, helping determine the best treatment (solution) for health (structural integrity).

Key Concepts

-

Maximum Principal Stress Theory: Involves failure when the maximum principal stress exceeds a critical level.

-

Maximum Shear Stress Theory: Centers on failure occurring when maximum shear stress reaches a critical point.

-

Distortional Energy Theory: Relates to energy stored within a material that can lead to failure when above certain thresholds.

Examples & Applications

An engineer tests a steel beam using a maximum shear stress theory and finds it fails at 300 MPa.

A material under compression is found to yield under a maximum principal stress of 500 MPa during testing.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Yielding leads to bending or a crack, buckling makes the structure lack.

Stories

Imagine a bridge; it stands strong under stress. But if it bends too much or twists, it may fail, just like a muscle can be strained too far!

Memory Tools

Remember: 'MPS - Maximum Principal Stress', 'MSS - Maximum Shear Stress', for easy recall of main theories.

Acronyms

TORD - Theories of failure

Tension

Overall

Rupture

and Distortion.

Flash Cards

Glossary

- Yielding

Permanent deformation of a material that occurs when the stress exceeds the yield strength.

- Buckling

A mode of failure characterized by a sudden lateral deflection of a structural member.

- Principal Stress

The normal stresses acting on a material in principal axes that can lead to failure.

- Shear Stress

The stress component that acts parallel to the cross-section of a material.

- Distortional Energy

The part of total strain energy in a material that causes distortion without a change in overall volume.

Reference links

Supplementary resources to enhance your learning experience.