Module I: Bolted and Welded Connections

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Connections

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we’ll start by discussing the evolution of structural connections, particularly the shift from riveted connections to bolted and welded alternatives. Who can explain what a rivet is?

A rivet is a cylindrical pin used to join two pieces of metal, typically driven through pre-drilled holes.

Great! Rivets were popular but are now seldom used due to their labor intensity. What alternative methods are often employed now?

Bolted and welded connections are now preferred for their ease and speed of installation.

Exactly! Bolted connections use high-strength bolts, while welded connections fuse materials. Let’s remember this with the acronym 'BOW' for Bolted, Omit Rivets, and Welded connections.

That's helpful! So, what's the main advantage of welded connections?

Welded connections are strong and rigid, making them suitable for prefabrication. Remember that rigid equals strong!

To summarize, we discussed riveted connections, the benefits of bolted and welded connections, and used 'BOW' to help remember these concepts. Does anyone have further questions?

Bolted Connection Design

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's delve deeper into bolted connection design. What are some key factors we need to consider?

We need to look at design strength, bolt arrangement, and edge distances.

Excellent! When determining bolt requirements, what steps do we follow?

We calculate the type and number of bolts needed based on the design load.

Correct! Then we check for shear and bearing. What’s important about edge distances?

They need to be sufficient to prevent any kind of tear-out failure.

Exactly! Remember the phrase ‘Think Safety First’ when designing these connections. Let’s summarize our points: We addressed design strength, bolt requirements, and edge distances. Any questions?

Welded Connection Design

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now we’ll explore welded connection design. Can anyone name the types of welds we commonly use?

Fillet welds and butt welds!

That's right! And what’s the difference in how we calculate strength for those types?

Fillet weld strength is based on the throat thickness, while butt welds assume full-section strength when executed correctly.

Exactly! A good mnemonic for this could be 'Full Throat Strength for Fillet.' Discussing throat thickness, what’s the minimum we need?

It’s 0.7 times the weld size for fillet welds.

Good job! To summarize, we highlighted weld types, calculated strengths, and the importance of throat thickness. Any questions?

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section elaborates on traditional riveted connections and highlights the advantages of bolted and welded connections in modern construction. It discusses the design principles of bolted and welded connections, application scenarios, and considerations for strength and load requirements.

Detailed

Module I: Bolted and Welded Connections

Introduction to Connections

This section provides an essential overview of riveted, bolted, and welded connections commonly used in structural engineering. Riveted connections, once the standard, are now rarely utilized in favor of bolting and welding due to their labor-intensive nature.

Bolted Connections

- High-Strength Friction Grip (HSFG) bolts and conventional black bolts are classified based on the strength needed for structural connections.

- Types of Bolted Connections:

- Bearing-type: Shear is transferred via the bolt bearing on the holes.

- Friction-type: Relies on friction created by pre-tensioned bolts to resist shear.

- Common Applications: Include beam-to-beam, beam-to-column, and bracket plates.

Welded Connections

- Weld Types: Welds can either be fillet or butt, depending on how they join the steel elements.

- Significance: Welds provide a strong, rigid connection suitable for prefabrication, enhancing overall structural integrity.

Design Principles

Bolted Connection Design

- Factors include design strength, bolt arrangement, and edge distances to prevent failures.

- Steps in Design: Determine bolt requirements, check loads, ensure proper distances based on standards.

Welded Connection Design

- Effective throat thickness and weld length are crucial to meet design forces effectively.

- Types to Consider: Continuous versus intermittent welds as per load requirements.

Special Considerations

- Understanding axial versus eccentric loading and its impact on design.

- Safety checks including prying action and local strengths are vital for bracket connections.

Conclusion

An in-depth understanding of bolted and welded connections is crucial for ensuring safe, reliable, and efficient structural designs to support both axial and complex loads.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to Riveted Connections

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Riveted Connections

Traditionally used before the widespread adoption of bolting and welding.

Rivets are cylindrical steel pins driven while hot through pre-drilled holes in the connected members, expanding to fill the hole as they cool.

Not common in modern structural steelwork due to labor intensity and better alternatives.

Detailed Explanation

Riveted connections represent an older method of joining steel parts, where rivets—hot-forged steel pins—are driven into precut holes. As they cool, they expand, locking the parts together. This method has largely fallen out of favor in favor of bolting and welding, which are quicker and require less manual labor.

Examples & Analogies

Think of riveted connections like connecting wooden parts using wooden dowels. Just like dowels must be precisely cut and glued, rivets need specific holes, and the process can be quite slow and labor-intensive. Traditionally, buildings were assembled this way, but today we prefer quicker methods, similar to how flat-pack furniture is assembled using screws nowadays.

Overview of Bolted Connections

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Bolted Connections

Bolted joints use high-strength bolts (HSFG) to connect structural steel members.

Preferred for ease, speed, and clean installation.

Types:

- Bearing-type: Shear transferred by bolt bearing on holes.

- Friction-type: Shear resisted by friction between connected plates, achieved by pre-tensioned bolts.

Common Applications: Beam-to-beam, beam-to-column, bracket plates.

Detailed Explanation

Bolted connections are a modern way to join metal parts, using high-strength bolts that provide a secure and reliable hold without the need for extensive labor. There are two main types: bearing-type bolts transfer shear through the hole's bearing, while friction-type bolts create a strong connection through tension. These joints are used in many applications, such as connecting beams to columns.

Examples & Analogies

Imagine assembling a large piece of furniture with bolts instead of nails. Bolted connections allow for easy assembly and disassembly, just as we can take apart flat-pack furniture for moving. Similar to how some items use pressure from bolts to hold together tightly (like joining two board pieces), structural applications rely on these connections to carry heavy loads.

Introduction to Welded Connections

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

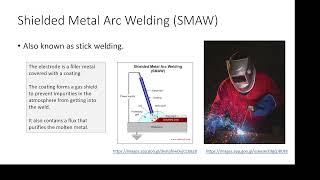

Welded Connections

Welds create joints by fusing steel parts using heat with/without filler.

Strong, rigid, and suited for prefabrication.

Types:

- Fillet welds: Triangular cross-section, common for lap, tee, and corner joints.

- Butt welds: Joining ends of plates typically in the same plane.

Detailed Explanation

Welded connections use heat to fuse pieces of steel together, creating a strong and rigid bond. Welds can be done with or without additional filler material. The two common types include fillet welds, which are used at various joint angles, and butt welds, used to connect the ends of plates. Welds are beneficial for prefabricated elements as they create a seamless connection.

Examples & Analogies

Think of welding like melting chocolate to fuse together two pieces of cake. Just as the melted chocolate creates a strong bond when it cools and sets, welding applies heat to steel parts, allowing them to fuse permanently. This method would make a cake structure incredibly solid, similar to how welded joints provide strength to steel structures.

Key Concepts

-

Riveted Connections: Transitioned to less usage, was once a common method.

-

Bolted Connections: Easier and faster installation, focused on HSFG bolts.

-

Welded Connections: Strong and rigid, made through heat fusing.

Examples & Applications

An example of a bolted connection would be the joint between steel beams in a building's framework.

A common application of welded connections is the joining of steel plates in bridge construction.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Welds so strong, they won't go wrong, bolted connections keep it along.

Stories

Imagine a bridge built with strong connections, where every bolt whispers its story of strength working together to carry heavy loads.

Memory Tools

Remember SET: Strength, Ease, and Timing for bolted connections.

Acronyms

BOW stands for Bolted, Omit Rivets, and Welded connections.

Flash Cards

Glossary

- Rivet

A cylindrical steel pin used to join metal parts.

- High Strength Friction Grip (HSFG)

A type of bolt that transfers loads through friction.

- Fillet Weld

A type of weld with a triangular cross-section used for connecting two surfaces at an angle.

- Butt Weld

A weld that joins two ends of plates in the same plane.

Reference links

Supplementary resources to enhance your learning experience.