DESIGN PHILOSOPHIES of ACI and AISC CODES

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Safety Provisions Overview

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today we will discuss the safety provisions that are vital in designing structures under ACI and AISC codes. Can anyone tell me why safety is so crucial?

I think it’s to ensure that structures can support unexpected loads.

Exactly! Structures need to carry reserve loads beyond normal expectations. What sort of variability do you think could affect resistance?

The materials used can vary in strength.

Good point! Variability in material strength, such as concrete versus steel, is significant. Remember, concrete often has greater variability than steel. Now, let’s summarize this key concept: variability in material strength is a critical consideration in design.

Load Variability and its Implications

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s discuss load variability. How do live loads differ from dead loads?

Live loads can change, while dead loads are constant.

Exactly! Live loads can fluctuate significantly, such as in pedestrian bridges. Can anyone think of why this might affect our safety factor?

If the live load can change, it could lead to unexpected stress on a structure.

Right! That’s why we need to account for the variability in live loads when determining our safety provisions. Remember: unpredictability in loads necessitates a higher safety factor.

Consequences of Failure

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s analyze the consequences of failure. What are some potential impacts of different structural component failures?

A beam might just fail locally, but a column failure could take down the whole building.

Exactly right! The implications of a failure can differ widely. Some failures provide warning signs, while others are abrupt. This is crucial in designing for safety.

So, we should design columns with a higher safety factor?

Correct! Components with catastrophic failure potential require more stringent safety measures. Let’s remember: assess consequences of failure when calculating safety factors.

Understanding the Ultimate Strength Method

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's discuss the ultimate strength method. Can anyone summarize what this method implies?

It helps estimate the maximum load a structure can handle, right?

Exactly! This method includes safety factors to ensure reliability, but there are limitations we should be aware of. What can you think of as a limitation?

It's tough to account for things like creep and shrinkage in concrete.

Correct! Creep and shrinkage indeed complicate the elastic analysis. Always remember the limitations as we apply the ultimate strength method!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section outlines the critical safety provisions necessary for designing structures according to ACI and AISC codes, addressing variability in resistance, loadings, and the consequences of failure. It highlights the importance of a reserve load and the ultimate strength method in ensuring structural integrity.

Detailed

Design Philosophies of ACI and AISC Codes

This section focuses on the design philosophies encapsulated within the ACI (American Concrete Institute) and AISC (American Institute of Steel Construction) codes. Central to these codes are safety provisions that are essential for all structural designs, ensuring that each structure can safely withstand loads that exceed typical usage.

Key Points:

- Safety Provisions must consider variability in both resistance and loadings.

- Variability in Resistance arises from:

- Differences in material strength (e.g., concrete exhibits greater variability than steel).

- Dimensional discrepancies in steel reinforcements in reinforced concrete.

- Simplifying assumptions during formula derivation.

- Variability in Loadings indicates that live loads fluctuate more significantly than dead loads, with some loads (like those from wind or seismic activity) being particularly unpredictable.

- Consequences of Failure must be evaluated:

- A beam's failure can lead to local collapse, while a column's failure can jeopardize the entire structure.

- Certain failures may provide warning signs, whereas others can occur abruptly.

- Structures that do not allow for load redistribution need higher safety factors.

- Ultimate Strength Method:

- This method employs safety factors to ensure reliability, but has its limitations like not properly accounting for concrete creep and shrinkage.

- It draws from experience rather than probabilistic approaches to establish safety factors.

- Allowable Strengths, as tabulated, help engineers quantify permissible stress levels in both steel and concrete. Notably, tension and compression strengths differ under AISC and ACI guidelines.

By integrating these concepts, the section emphasizes the importance of creating safe, economical structures through the principles outlined in the ACI and AISC guidelines.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Safety Provisions Overview

Chapter 1 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Structures and structural members must always be designed to carry some reserve load above what is expected under normal use. This is to account for:

Detailed Explanation

This chunk introduces the concept of safety provisions in structural design. Safety provisions ensure that structures can handle unexpected loads or variances due to material properties or environmental factors.

Examples & Analogies

Imagine a bridge designed to carry 10 tons of weight. Safety provisions mean the actual design can carry significantly more, say 12 tons, to ensure safety in case of unexpected heavy vehicles crossing.

Variability in Resistance

Chapter 2 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The actual strengths (resistance) of structural elements will differ from those assumed by the designer due to:

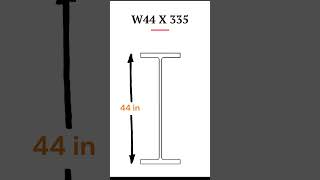

1. Variability in the strength of the material (greater variability in concrete strength than in steel strength).

2. Differences between the actual dimensions and those specified (mostly in placement of steel rebars in R/C).

3. Effect of simplifying assumptions made in the derivation of certain formulas.

Detailed Explanation

This chunk discusses the variability in resistance that structural designs face. It highlights three main factors: the natural differences in material strength (like concrete vs. steel), potential discrepancies in construction dimensions, and the simplifications that engineers must make when creating formulas for design.

Examples & Analogies

Think of baking a cake: you might assume you have all the ingredients, but if the eggs are smaller than usual (variability in ingredients) or the oven temperature is off (miscalculation in dimensions), the final product (your cake) may not turn out as expected.

Variability in Loadings

Chapter 3 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

All loadings are variable. There is a greater variation in the live loads than in the dead loads. Some types of loadings are very difficult to quantify (wind, earthquakes).

Detailed Explanation

This section explains that loads on a structure can change over time and are not always predictable. Live loads (like people or cars) can vary significantly compared to dead loads (like the weight of the building itself). Additionally, forces from nature, like winds or earthquakes, contribute to this unpredictability.

Examples & Analogies

Consider a parked car on a bridge, representing a live load. If a strong wind suddenly blows (another load), the bridge structure must handle that unanticipated force without any issues, much like a waiter adjusting their stance when carrying multiple plates to avoid dropping them.

Consequences of Failure

Chapter 4 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

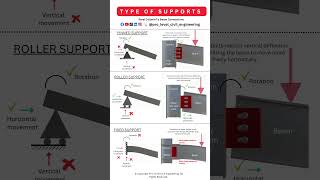

The consequence of a structural component failure must be carefully assessed. The collapse of a beam is likely to cause a localized failure... if no redistribution of load is possible (as would be the case in a statically determinate structure), a higher safety factor must be adopted.

Detailed Explanation

This chunk focuses on the importance of understanding the consequences of structural failure. Different components have varying impacts on overall stability. Some failures might be manageable while others can lead to total collapse. In simpler structures, a stronger safety margin is essential due to limited options for load redistribution.

Examples & Analogies

Imagine a chain made up of several links; if one link fails, it can weaken or break the entire chain. In contrast, if that link had a safety net, it prevents the whole chain from falling apart, much like how structures use safety factors.

Purpose of Safety Provisions

Chapter 5 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The purpose of safety provisions is to limit the probability of failure and yet permit economical structures.

Detailed Explanation

This section summarizes the ultimate goal of safety provisions—they protect against failure while allowing for cost-effective designs. It's a balance between ensuring safety and managing expenses in construction.

Examples & Analogies

Think of it like buying a car. You want one that is safe (with strong safety provisions) but also affordable. Manufacturers aim to provide a balanced approach to safety features (like airbags) without inflating the price excessively.

Factors in Determining Safety Provisions

Chapter 6 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The following items must be considered in determining safety provisions:

1. Seriousness of a failure, either to humans or goods.

Detailed Explanation

The final chunk highlights key considerations for safety provisions, specifically focusing on the severity of potential failures. Each type of structural failure can have different consequences, and these must be carefully evaluated during the design process.

Examples & Analogies

Picture a playground. If a swing is designed poorly, a child falling off may just get a scrape, but if a slide collapses, it could lead to more severe injuries or accidents. Designers must evaluate the risks to decide how sturdy their designs need to be.

Key Concepts

-

Reserve Load: Structures should be designed for loads greater than those expected during normal use.

-

Variability: Material strength and loadings can fluctuate, influencing design safety.

-

Failure Consequences: Different structural failures carry varying risks; understanding this guides safety factors.

Examples & Applications

In reinforced concrete, the placement of steel rebars can vary from the specifications, affecting structural integrity.

An office building may be designed with a higher safety factor than a bridge due to the potential consequences of structural failure.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

When designing to support the strain, ensure safety provisions, don't be vain.

Stories

Imagine you’re building a bridge. You wouldn’t only think of average traffic; you’d factor in an unexpected flood! That’s how reserves work.

Memory Tools

S.A.F.E. - Safety, Assessment, Factors, Evaluation.

Acronyms

L.R.F. - Load Reserve Factor.

Flash Cards

Glossary

- Safety Provisions

The measures taken in design to ensure a structure can safely support unexpected loads.

- Variability in Resistance

The variations that occur in material strength and dimensions which affect the load-carrying capacity of structural elements.

- Live Loads

Variable loads on a structure, such as people, furniture, and vehicles.

- Dead Loads

Constant loads acting on a structure, typically the weight of the structure itself.

- Ultimate Strength Method

A design approach that uses safety factors to account for loads and material properties.

Reference links

Supplementary resources to enhance your learning experience.