PRESTRESSED CONCRETE

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Prestressed Concrete

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're discussing prestressed concrete. Can anyone tell me why longer spans in beams are architecturally desirable?

I think it's because they look better and maybe allow more space beneath them.

Exactly! However, conventional reinforced concrete beams have limitations, especially due to cracking under tension. This is where prestressing comes into play.

What does prestressing actually do?

Great question! Prestressing introduces an initial compressive stress that can counteract tension stresses caused by loads. This results in reduced cracking and improved structural performance.

How does that work in practice?

In practice, we apply this initial stress either by pretensioning before the concrete is poured or post-tensioning after the concrete cures.

Can you recap that? What's the main benefit again?

Absolutely! The primary benefit of prestressed concrete is the enhanced control over tension and cracking, which leads to longer-lasting and more economical structures.

Methods of Prestressing

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s delve deeper into the two methods of prestressing we mentioned. Who can name the two types?

I remember pretensioning and post-tensioning!

That's correct! In pretensioning, we stress the steel tendons before pouring concrete, which bonds well once set. Can anyone think of a situation in which this method would be beneficial?

Maybe when we need to ensure the concrete has the highest strength immediately?

Exactly! Now, what about post-tensioning?

That's when we pour first and then stress the cables, right?

Correct! This method can be more flexible for longer spans and allows for adjustments after the concrete cures.

Could you summarize the pros of each method?

Sure! Pretensioning is great for high early strength, while post-tensioning provides flexibility and the ability to mitigate imperfections after hardening.

Importance of High Strength Materials

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's discuss materials used in prestressed concrete. Why do you think we choose high strength steel for prestressing?

Wouldn’t it be because it can handle higher loads and stresses?

Correct! High yield strength prevents high losses due to shrinkage and creep, which can reduce effectiveness. Who can recall an example of these stresses?

Do we talk about creep and shrinkage? They affect the length and performance of the concrete over time, right?

Exactly! If we don't consider these, we might end up with unacceptable stress losses.

What happens if stress loss is too high?

Good question! High stress loss leads to insufficient prestressing, which can result in structural failure. We must carefully design the prestressing to avoid this.

Can you finish with key takeaways on material selection?

Certainly! Use high yield strength materials to minimize cracking risks and losses due to shrinkage and creep, ensuring structural integrity.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section explores the advantages of prestressed concrete, including improved economy, deflection and crack control, and the use of high-strength materials. It describes two primary types of prestressed concrete: pretensioning and post-tensioning, along with the significance of these methods in construction.

Detailed

Detailed Summary

Introduction to Prestressed Concrete

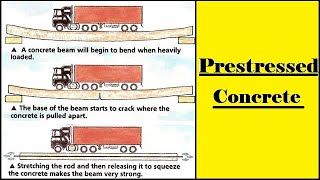

Prestressed concrete combines the benefits of reinforced concrete while addressing its limitations for longer spans. In traditional concrete, tensile stress can lead to cracking, and applying initial compressive stress through prestressing helps mitigate these risks.

Advantages of Prestressed Concrete

- Economy: Reduces material costs and allows for longer spans without thickening the beam.

- Deflection and Crack Control: By introducing stress opposite to the load, it minimizes deflection and cracking, ultimately enhancing durability.

- Durability and Fatigue Strength: Prestressed structures exhibit longer life spans, as they are less susceptible to corrosion and fatigue.

- Longer Spans: Enables wider spaces in designs, maintaining aesthetic appeal.

Methods of Prestressing

There are two primary methods to achieve prestressing:

1. Pretensioning: Steel tendons are tensioned before concrete is poured.

2. Post-tensioning: Concrete is poured, hardened, and then steel tendons are tensioned within the concrete.

Materials Used and Their Importance

Prestressed concrete beams often utilize higher strength materials, with compressive strengths significantly above standard reinforced concrete. Effective design must account for shrinkage and creep to ensure the structure performs as needed over its lifespan.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to Prestressed Concrete

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Beams with longer spans are architecturally more appealing than those with short ones. However, for a reinforced concrete beam to span long distances, it would have to have to be relatively deep (and at some point the self weight may become too large relative to the live load), or higher grade steel and concrete must be used. However, if we were to use a steel with f much higher than 60 ksi in reinforced concrete (R/C), then to take full advantage of this higher yield stress while maintaining full bond between concrete and steel, will result in unacceptably wide crack widths. Large crack widths will in turn result in corrosion of the rebars and poor protection against fire. One way to control the concrete cracking and reduce the tensile stresses in a beam is to prestress the beam by applying an initial state of stress which is opposite to the one which will be induced by the load.

Detailed Explanation

In this chunk, we learn that long-span beams are more visually appealing, but they face challenges due to increased self-weight. To counteract these challenges, engineers consider using higher grades of steel and concrete. Prestressing helps mitigate the cracking and tensile stress issues by creating an initial compression in the concrete, which opposes the stresses caused by the load.

Examples & Analogies

Imagine a bow and arrow: when you pull the string back (prestress), the bow is under tension. This tension helps the bow hold its shape and prepares it to shoot stronger arrows. Similarly, prestressing a concrete beam helps it resist the pulls of weight and use its materials more effectively.

Methods of Prestressing Concrete

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

For a simply supported beam, we would then seek to apply an initial tensile stress at the top and compressive stress at the bottom. In prestressed concrete (P/C) this can be achieved through prestressing of a tendon placed below the elastic neutral axis. Main advantages of P/C: Economy, deflection & crack control, durability, fatigue strength, longer spans. There are two types of Prestressed Concrete beams: Pretensioning: Steel is first stressed, concrete is then poured around the stressed bars. When enough concrete strength has been reached the steel restraints are released. Postensioning: Concrete is first poured, then when enough strength has been reached a steel cable is passed thru a hollow core inside and stressed.

Detailed Explanation

This chunk explains the application of stresses in a prestressed concrete beam. By applying initial tensile stress at the top and compressive stress at the bottom, we can achieve improved performance of the beam. It introduces two methods of prestressing: pretensioning, where stresses are applied before the concrete hardens, and postensioning, where stresses are added after the concrete has set. The benefits of prestressed concrete include economic advantages, crack control, durability, resistance to fatigue, and the ability to span longer distances.

Examples & Analogies

Think of a trampoline: before using it (like pouring concrete), the springs (prestressing tendons) are already stretched (pretensioned). When you jump on it, it supports your weight without sagging too much. In construction, this means we can safely build longer bridges or tall buildings.

Materials in Prestressed Concrete

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

P/C beams usually have higher compressive strength than R/C. Prestressed beams can have f c' as high as 8,000 psi. The importance of high yield stress for the steel is illustrated by the following simple example. If we consider the following: 1. An unstressed steel cable of length l s 2. A concrete beam of length l c 3. Prestress the beam with the cable, resulting in a stressed length of concrete and steel equal to l = l = l s0 c0 4. Due to shrinkage and creep, there will be a change in length Δl = (εsh + εcr)l c. We want to make sure that this amount of deformation is substantially smaller than the stretch of the steel (for prestressing to be effective).

Detailed Explanation

In this section, we explore the materials used in prestressed concrete. These beams are stronger due to a higher allowable compressive strength compared to regular reinforced concrete. The section emphasizes the significance of using high-yield-strength steel, explaining that as the steel is prestressed, any changes in length due to shrinkage or creep must be kept smaller than the elongation of the steel. This allows for effective prestressing.

Examples & Analogies

Consider a high-quality rubber band that can stretch but also returns to its original form: if we stretch it too much, it won't be effective at holding anything. Similarly, the materials used in prestressed concrete must be carefully managed to ensure they can handle the stresses without failing.

Loss of Prestress

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Having shown that losses would be too high for low strength steel, we will use strands usually composed of 7 wires. Grade 250 or 270 ksi. Note that yield stress is not well defined for steel used in prestressed concrete; usually we take 1% strain as effective yield. Steel relaxation is the reduction in stress at constant strain (as opposed to creep which is reduction of strain at constant stress). Relaxation occurs indefinitely and produces.

Detailed Explanation

This chunk discusses the potential loss of prestress in concrete beams due to various factors, particularly focusing on the importance of using strong steel strands. It explains the concepts of yield stress and steel relaxation, emphasizing that flexibility in steel performance can cause stress loss over time, making it critical to choose the appropriate materials and methods.

Examples & Analogies

Think of a stretchable toy that eventually loses its bounce as you play with it. Over time, the material may not return to its original state as effectively. In construction, understanding and mitigating prestress loss is just as crucial for ensuring long-term performance.

Key Concepts

-

Prestressing: The technique to introduce initial compressive stress to mitigate tensile forces in concrete.

-

Pretensioning: Before pouring concrete, tendons are tensioned.

-

Post-tensioning: Concrete is poured, then tendons are tensioned post-curing.

Examples & Applications

An example of pretensioning is when highway bridge beams are fabricated in a plant, where the tendons are placed in tension before concrete is poured.

Post-tensioning is exemplified in high-rise buildings where concrete slabs are stressed after reaching sufficient strength, allowing for longer spans between columns.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

When tensile cracks do show, prestress the beams so they don't grow.

Stories

Imagine a bridge where engineers decided to pre-tension the wires before pouring concrete. They watched as their creation stood tall, without the cracks of stress.

Memory Tools

Remember 'Penny for Your Thoughts.' P = Pretension and P = Post-tension.

Acronyms

PACT

Prestress

Apply

Control Tension.

Flash Cards

Glossary

- Prestressing

The technique of applying an initial compressive stress to a concrete element to counteract tensile stresses during service.

- Pretensioning

A method where steel tendons are tensioned before casting the concrete.

- Posttensioning

A method involving pouring concrete first, allowing it to cure, and then tensioning the steel tendons afterward.

- Creep

The gradual increase in deformation under a sustained load over time.

- Shrinkage

The reduction in volume of concrete as it sets and cures, causing potential tensile stresses.

Reference links

Supplementary resources to enhance your learning experience.