Factors affecting pavement design

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Traffic and Loading

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today we're diving deep into the first major factor affecting pavement design: Traffic and Loading. Can anyone tell me what they think are some critical aspects involved?

Is it related to how heavy the vehicles are?

Absolutely, Student_1! The wheel load is crucial because it determines how deep our pavement needs to be to prevent subgrade failure. What else do we consider with traffic?

Maybe how frequently the loads are applied?

Exactly! Repeated loads cause cumulative deformations. That's why we often base our designs on the total number of standard axle loads, which in many cases is about 80 kN. And can anyone explain the significance of contact pressure?

Isn't it about the area where the tire meets the pavement?

Correct! Contact pressure affects stress distribution. Good job! Always remember: C for Contact, L for Load - our memory aid! Let's move on to explore structural models.

Structural Models

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

We talked about traffic and loading factors, now let's discuss structural models. Can anyone define what a structural model does?

Does it help us understand how the pavement reacts to loads?

Exactly! The layered elastic model, for instance, gives us insights into stress, strain, and deformations within pavement layers. It assumes uniform material behavior. Can someone tell me why that’s beneficial?

It makes calculations simpler, right?

Spot on, Student_1! These models help us compute responses without overly complex mathematics. Remember, E for Elasticity, S for Simplicity. Now let's look at material characterization.

Material Characterization

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, we have material characterization. Why do you think it's important?

It tells us how the materials will behave, right?

Exactly! Each pavement's elastic modulus and Poisson's ratio are vital for understanding their response. Can anyone explain the concept of resilient modulus?

Isn't it the modulus used under repeated loading?

Exactly! Resilient modulus is crucial for predicting performance under real-world conditions. Remember: M for Modulus, R for Resilience! Now, let’s summarize this discussion before we end.

Environmental Factors

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let’s talk about environmental factors. Why do you think temperature affects pavement design differently for asphalt and concrete?

Because they react differently to heat, right? Asphalt gets softer, while concrete can curl.

Exactly! Temperature affects the resilient modulus in asphalt and creates differential stresses in concrete. Can someone remind me of another environmental consideration?

Precipitation! It can cause issues with drainage.

Great job! Poor drainage can lead to shear strength loss and pavement instability. So, T for Temperature, P for Precipitation. And that's our session for today!

Summary of Key Concepts

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s wrap up what we’ve learned today. Who can list the four main factors affecting pavement design?

Traffic and loading, structural models, material characterization, and environmental factors!

Excellent! Remember your memory aids and keep these factors in mind as they are crucial for good pavement design. E for Environmental Factors, M for Material Properties. That's all for today's session!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Pavement design is significantly influenced by multiple factors which can be grouped into four primary categories: traffic and loading, structural models, material characterization, and environmental conditions. Key traffic factors include wheel loads and their repetitions, while structural models analyze pavement responses. Material characteristics such as elastic modulus are crucial, and environmental factors like temperature and precipitation impact pavement performance.

Detailed

Detailed Overview of Factors Affecting Pavement Design

Pavement design is a complex process that hinges on several critical factors, which can be classified into four main categories:

- Traffic and Loading:

- This is the most crucial aspect of pavement design. Factors here include contact pressure from wheels, the wheel load itself, axle configurations, moving loads, and the frequency of load applications. Understanding these elements helps in determining the necessary pavement depth to prevent failure of the underlying subgrade.

- Contact Pressure: Derived from the tyre pressure, affecting the area where wheels interact with pavement. It’s typically treated as a circular area for simplicity.

- Wheel Load: Determinates the pavement depth requirements to protect the subgrade soil from damage.

- Axle Configuration: The arrangement of axles supports heavier loads and influences stress distribution.

- Moving Loads: Vehicles at slow speeds can cause more damage than those moving faster, which reduces conveyed stresses and deformations.

- Repetition of Loads: The frequency of load application significantly contributes to total pavement deformation, influencing design metrics based on average single axle loads.

- Structural Models:

- This involves analytical approaches like layered elastic models which compute responses (stress, strain, deformations) in pavements when subjected to loads, assuming properties that are consistent across each layer.

- Material Characterization:

- This includes specifying elastic moduli and Poisson's ratios for both flexible and rigid pavements. It involves understanding how materials behave under different loads and conditions in terms of their elastic properties.

- Environmental Factors:

- Environmental conditions such as temperature fluctuations and precipitation affect material performance. Temperature may lead to asphalt resilient modulus changes or concrete slab curling. Ground water levels impacted by precipitation can breach shear strength and lead to pavement instability.

In conclusion, the interplay between these factors shapes the design criteria necessary for effective pavement construction to withstand anticipated traffic and environmental stresses.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Overview of Pavement Design Factors

Chapter 1 of 14

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

In the previous chapter we had discussed about the types of pavements and their failure criteria. There are many factors that affect pavement design which can be classified into four categories as traffic and loading, structural models, material characterization, and environment. They will be discussed in detail in this chapter.

Detailed Explanation

This chunk introduces the topic of pavement design by summarizing the focus of the previous chapter on pavement types and failure criteria. It highlights that pavement design is influenced by four main factors: traffic and loading conditions, structural analysis models, characteristics of the materials used, and environmental factors. Each of these will be explained in detail in the following sections.

Examples & Analogies

Think of designing a road like baking a cake. The types of ingredients (traffic and loading, structural models, materials, and environment) you use will determine how the cake turns out. If some ingredients are off, like too much sugar or flour, your cake (or pavement) could collapse or not function as intended.

Traffic and Loading

Chapter 2 of 14

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Traffic is the most important factor in the pavement design. The key factors include contact pressure, wheel load, axle configuration, moving loads, load, and load repetitions.

Detailed Explanation

This chunk emphasizes the significance of traffic as the foremost factor affecting pavement design. It outlines the various aspects of traffic that need to be considered: contact pressure (the pressure exerted by vehicle tires), the weight of vehicles (wheel load), how vehicles are arranged (axle configuration), the effects of vehicle speed (moving loads), and how often vehicles drive over the pavement (load repetitions). Together, these factors influence the selection of materials and structural integrity needed for durable pavement.

Examples & Analogies

Imagine a sponge under a heavy book. If the book stays there for a little while, the sponge will bounce back, but if the book is heavy and sits there for a long time, the sponge will remain compressed. Similarly, how often and how heavy vehicles drive on a pavement can 'compress' it, leading to wear and tear over time.

Contact Pressure

Chapter 3 of 14

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

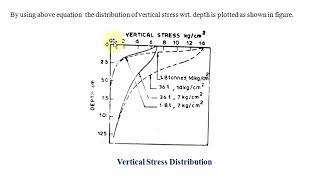

The tyre pressure is an important factor, as it determines the contact area and the contact pressure between the wheel and the pavement surface. Even though the shape of the contact area is elliptical, for the sake of simplicity in analysis, a circular area is often considered.

Detailed Explanation

Contact pressure refers to how much weight is spread over the pavement by the tires of vehicles. It is influenced by the pressure of the tires themselves and affects how the pavement responds to that pressure. Although the area where the tire meets the pavement is actually an ellipse, for easier calculations, engineers often assume it to be circular. Understanding contact pressure helps engineers design pavement that can withstand the stresses imposed by traffic.

Examples & Analogies

Consider standing on a soft surface like sand. If you stand on it with both feet together, your weight is distributed over a smaller area compared to if you stand on one leg. The more weight concentrated over a smaller area can cause deeper impressions in the sand. This illustrates how contact pressure works in pavement design.

Wheel Load

Chapter 4 of 14

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The next important factor is the wheel load which determines the depth of the pavement required to ensure that the subgrade soil does not fail. Wheel configuration affects the stress distribution and deflection within a pavement. Many commercial vehicles have dual rear wheels which ensure that the contact pressure is within the limits. The normal practice is to convert dual wheel into an equivalent single wheel load so that the analysis is made simpler.

Detailed Explanation

Wheel load refers to the weight carried by each wheel of a vehicle, which plays a crucial role in determining how deep the pavement must be to support the load without damaging the soil underneath. The configuration of how wheels are arranged on a vehicle can alter how the load is spread across the pavement. For instance, dual rear wheels distribute the load better and lower the stress on the pavement. To simplify calculations, engineers often convert this dual load into a single equivalent load for analysis.

Examples & Analogies

Imagine walking on a soft muddy path. If you walk with both feet wide apart, the weight is spread out; if you jump on one foot, you press down harder on that point and may sink in. Similarly, vehicles with multiple wheels can spread their weight to prevent damaging the surface.

Axle Configuration

Chapter 5 of 14

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The load carrying capacity of the commercial vehicle is further enhanced by the introduction of multiple axles.

Detailed Explanation

This chunk discusses how having multiple axles on commercial vehicles improves their ability to carry heavy loads without causing damage to the pavement. Each axle spreads the weight of the vehicle over a larger area, reducing the pressure any single point on the pavement must endure, which is important for maintaining the pavement's integrity and lifespan.

Examples & Analogies

Think about how a flatbed truck can carry a heavy load more effectively than a smaller car. The multiple axles on the truck distribute the weight better, just like how having more friends carry a heavy box can make it easier and prevent any one person from having to bear the whole weight.

Moving Loads

Chapter 6 of 14

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The damage to the pavement is much higher if the vehicle is moving at creep speed. Many studies show that when the speed is increased from 2 km/hr to 24 km/hr, the stresses and deflection reduced by 40 per cent.

Detailed Explanation

Pavements endure more damage when vehicles move very slowly (which is referred to as 'creep speed'). Research has indicated that increasing the speed of vehicles significantly reduces the stresses and deformation on the pavement. This means that quicker-moving vehicles exert less damaging pressure over time, which is why traffic speed is an important factor in pavement design.

Examples & Analogies

Imagine pushing a heavy chair across the floor. If you push it gently and slowly, it may drag and create more friction; if you push it quickly, it glides more easily with less force applied over time. This reflects how the speed of vehicles on a pavement affects the stress on the surface.

Repetition of Loads

Chapter 7 of 14

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The influence of traffic on pavement does not only depend on the magnitude of the wheel load, but also on the frequency of the load applications. Each load application causes some deformation and the total deformation is the summation of all these. Although the pavement deformation due to single axle load is very small, the cumulative effect of a number of load repetitions is significant. Therefore, modern design is based on total number of standard axle loads (usually 80 kN single axle).

Detailed Explanation

This section highlights that repeated traffic loads lead to significant cumulative damage to pavements. Each time a vehicle passes over the pavement, even though the immediate damage may be small, over time these small damages add up, causing serious wear. Engineers use standards (like the 80 kN single axle load) to predict how many times the pavement will experience such loads to design for durability.

Examples & Analogies

Think of it like a small, sharp rock on a sidewalk. If someone steps on it just once, the impact is minor. But if hundreds of people step on it repeatedly, the rock creates a noticeable indentation over time. Similarly, the more loads a pavement endures, the more wear and deformation it experiences.

Structural Models

Chapter 8 of 14

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The structural models are various analysis approaches to determine the pavement responses (stresses, strains, and deflections) at various locations in a pavement due to the application of wheel load. The most common structural models are layered elastic model and visco-elastic models.

Detailed Explanation

This chunk introduces two main types of structural models used to analyze how pavements respond under load: layered elastic models, which view pavement layers as uniform materials that can 'bounce back' after being loaded, and visco-elastic models, which take into account the time-dependent behavior of materials. Understanding these models helps engineers predict how a pavement will behave in real life under different loads.

Examples & Analogies

Imagine a sponge (layered elastic) and a rubber band (visco-elastic). The sponge bounces back after being compressed, while the rubber band takes time to fully extend back to its original shape. Similarly, pavements can act differently based on their structure and the timing of how loads are applied.

Layered Elastic Model

Chapter 9 of 14

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

A layered elastic model can compute stresses, strains, and deflections at any point in a pavement structure resulting from the application of a surface load. Layered elastic models assume that each pavement structural layer is homogeneous, isotropic, and linearly elastic. In other words, the material properties are same at every point in a given layer and the layer will rebound to its original form once the load is removed.

Detailed Explanation

The layered elastic model helps engineers calculate how different layers of a pavement react to loads. It treats each layer of the pavement as if it were made up of materials that have the same properties throughout. When weight is applied, the model assumes that the layers will return to their original shape after the load is no longer present, which simplifies calculations and predictions of pavement performance.

Examples & Analogies

Imagine a stack of pancakes. When you press down on them (like applying a load), they flatten a bit but will bounce back if you remove your hand. This visual shows how a layered elastic model processes loads on pavement layers.

Material Characterization

Chapter 10 of 14

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The following material properties should be specified for both flexible and rigid pavements. When pavements are considered as linear elastic, the elastic moduli and Poisson ratio of subgrade and each component layer must be specified. If the elastic modulus of a material varies with the time of loading, then the resilient modulus, which is the elastic modulus under repeated loads, must be selected in accordance with a load duration corresponding to the vehicle speed. When a material is considered non-linear elastic, the constitutive equation relating the resilient modulus to the state of the stress must be provided.

Detailed Explanation

Material characterization focuses on understanding how different materials respond to stresses. For effective pavement design, specific properties like elastic moduli (stiffness) and Poisson's ratio (how materials expand when compressed) must be defined. When materials exhibit changes in response over time (due to repeated loads), these factors must be considered to ensure accurate modeling and planning of pavement longevity.

Examples & Analogies

Think of a balloon. When you first stretch it, it might expand easily, but if you keep stretching it too much, it eventually doesn't bounce back like it did before. Understanding how materials behave under different conditions is crucial to knowing how they can be used effectively in pavement design.

Environmental Factors

Chapter 11 of 14

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Environmental factors affect the performance of the pavement materials and cause various damages. Environmental factors that affect pavement are of two types, temperature and precipitation.

Detailed Explanation

This section introduces how environmental influences, such as temperature changes and rainfall, play a vital role in the performance of pavements. Extreme temperatures can weaken materials or cause them to crack, while water can infiltrate the pavement and affect its structural strength. Recognizing these factors is crucial for pavement design, as they can lead to premature failure if not adequately accounted for.

Examples & Analogies

Think about wearing different clothes in summer versus winter. Hot temperatures can cause lightweight materials to sag or melt, while snow and rain can soak and weaken them. Pavements, much like clothing, need to be designed for the environmental conditions they'll experience to ensure they last.

Impact of Temperature on Pavements

Chapter 12 of 14

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The effect of temperature on asphalt pavements is different from that of concrete pavements. Temperature affects the resilient modulus of asphalt layers, while it induces curling of concrete slabs. In rigid pavements, due to difference in temperatures of top and bottom of slab, temperature stress or frictional stresses are developed. While in flexible pavements, dynamic modulus of asphaltic concrete varies with temperature. Frost heave causes differential settlements and pavement roughness. The most detrimental effect of frost penetration occurs during the spring breakup period when the ice melts and the subgrade is in a saturated condition.

Detailed Explanation

This chunk illustrates how temperature affects pavement materials differently. For example, asphalt softens in heat and becomes more pliable, while concrete can curl due to temperature differences between its top and bottom. These changes can lead to issues like cracking or uneven surfaces. Frost heave, when frozen ground thaws and expands, also creates challenges for pavements, particularly in spring. Understanding these effects helps engineers design pavements that can withstand these environmental changes.

Examples & Analogies

Imagine how a chocolate bar behaves in the sun compared to a cookie. The chocolate melts and becomes soft, while the cookie may crack if it gets too warm. Pavements react similarly to temperature changes; each material responds differently based on the conditions.

Impact of Precipitation

Chapter 13 of 14

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The precipitation from rain and snow affects the quantity of surface water infiltrating into the subgrade and the depth of the groundwater table. Poor drainage may bring lack of shear strength, pumping, loss of support, etc.

Detailed Explanation

This chunk discusses how rain and snow impact pavements. When weather brings heavy rains or snow, water can seep into the ground below the pavement, which can weaken the soil structure that supports the pavement. If the drainage systems are inadequate, this added moisture can lead to problems like erosion and loss of structural support, making the pavement more susceptible to damage.

Examples & Analogies

Think of a sponge. If you soak it in water, it becomes heavy and retains moisture, losing its shape. Similarly, when too much water gets into the ground beneath a pavement, it loses its strength, which can lead to cracking and weakening of the surface.

Summary of Pavement Design Factors

Chapter 14 of 14

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Several factors affecting pavement design were discussed, the most important being wheel load. Since pavements are designed to take moving loads, slow moving loads and static loads can be detrimental to the pavement. Temperature also influences pavement design, especially the frost action which is very important in cold countries.

Detailed Explanation

This summary reinforces the critical factors determining pavement design, reiterating that wheel load is paramount among them. It also emphasizes that not only moving loads but also slow-moving or stationary loads can damage pavement. Temperature changes are another significant factor, particularly the impact of frost in colder regions which must be considered when designing pavements.

Examples & Analogies

Consider building a bridge. You must consider heavy trucks moving quickly across it, as well as the challenges of snow and icy conditions. Every factor plays a role in ensuring the bridge lasts over time, just as it does in pavement design.

Key Concepts

-

Traffic Impact: Involves wheel load, axle configurations, and load repetitions.

-

Structural Models: Frameworks like layered elastic models used to analyze pavement behavior.

-

Material Properties: Elastic modulus, Poisson's ratio, and their significance in pavement performance.

-

Environmental Factors: The effects of temperature and precipitation on pavement materials.

Examples & Applications

For traffic and loading: A truck with dual rear wheels has its load distributed better, reducing stress compared to single wheels.

For environmental factors: Asphalt pavements may soften in high temperatures, impacting load-bearing capacity.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

For paving, keep the load light, ensure that layers are just right.

Stories

Imagine a busy street where a truck rolls by. If no one manages the load right, the surface might cry. Various weather can play a part, so understanding is quite smart.

Memory Tools

To recall the factors: T for Traffic, S for Structure, M for Materials, and E for Environment.

Acronyms

Remember TS— That's Traffic and Structure for design success!

Flash Cards

Glossary

- Contact Pressure

The pressure between the wheel and pavement surface determined by tire pressure and contact area.

- Wheel Load

The weight exerted by the vehicle wheels on the pavement, driving the necessary design depth.

- Axle Configuration

The arrangement of axles in a vehicle that affects the stress distribution in pavement.

- Layered Elastic Model

An analytical model used to compute pavement response to surface loading, assuming homogeneous and isotropic layer properties.

- Resilient Modulus

The modulus of elasticity used for materials under repeated loading conditions.

- Environmental Factors

Conditions such as temperature and precipitation that affect pavement performance.

Reference links

Supplementary resources to enhance your learning experience.