Dry Mix Design

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Selection of Aggregates

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today we'll start by discussing the selection of aggregates used in bituminous paving mixtures. Can anyone tell me why the type of aggregate matters?

Is it because different types of aggregates affect the stability of the mix?

Exactly! Coarse aggregates provide stability through interlocking and friction. What about fine aggregates?

They help fill the voids between coarse aggregates!

Right! And mineral fillers play a role too, mainly as void fillers. An easy way to remember this is "CFS" for Coarse, Fine, and Filler. Let's summarize: selecting the right aggregates is crucial as they directly affect the stability and performance of the mix.

Aggregate Gradation

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's talk about aggregate gradation. Why do you think the size distribution of aggregates is important?

I think it affects the density and how well the mix can hold up over time.

Good thought! The right gradation minimizes void space which increases the density of the mix. Remember this key point: 'good contact equals higher stability.' What happens if there are too many small particles?

There might not be enough space for the binder, right?

Correct! There needs to be some void space for the binder, drainage, and even resistance to frost. Let's finalize this point: the ideal gradation balances density with sufficient void space.

Proportioning of Aggregates

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Lastly, we have proportioning. What methods can we use for determining the right proportions of aggregates?

We could use a trial and error method!

That's one method, yes! Trial and error can help us find the right mix, but what about graphical methods?

I remember something about triangular charts!

Exactly! Triangular charts are useful when working with three aggregates. Finally, there’s the analytical method which uses equations. This method is becoming more popular with the help of computers. Remember: 'Trial and Graphical lead to Analytical solutions!'

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section discusses the three key steps in dry mix design: selection of aggregates, aggregate gradation, and proportioning. It highlights how varying aggregate types influences the stability and performance of bituminous mixtures, with practical examples and methods provided for combining aggregates efficiently.

Detailed

Detailed Summary of Dry Mix Design

Overview

The primary goal of dry mix design is to find the optimal mix of mineral aggregates in order to achieve maximum density, which is crucial for the performance of bituminous paving mixtures.

Key Steps in Dry Mix Design

- Selection of Aggregates: This involves choosing aggregates classified as coarse, fine, or filler, where each type plays a critical role in stability. Coarse aggregates contribute through interlocking and friction, fine aggregates fill voids, and mineral fillers assist in minimizing void gaps.

- Aggregate Gradation: The arrangement of aggregates greatly affects the mix properties, such as density and stability. The ideal gradation minimizes void space while maintaining some necessary voids for binder space and drainage. Fuller’s Law describes an optimal particle size distribution.

- Proportioning of Aggregates: Methods for this step include trial and error, graphical methods (like the triangular chart), and analytical methods which use equations to determine the right proportions of each aggregate type.

The chapter concludes with an example showing how to achieve a specific gradation using different aggregates, emphasizing the practical application of theoretical concepts in real-world scenarios.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Overview of Dry Mix Design

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The objective of dry mix design is to determine the amount of various sizes of mineral aggregates to use to get a mix of maximum density. The dry mix design involves three important steps, viz. selection of aggregates, aggregates gradation, and proportion of aggregates, which are discussed below.

Detailed Explanation

Dry mix design is a critical process in constructing bituminous paving mixtures. Its primary goal is to identify the right amounts of different mineral aggregates needed to achieve the highest possible density in the mix. There are three crucial stages in this process: first, selecting the appropriate types of aggregates; second, understanding how these aggregates should be graded; and third, determining the correct proportions of these aggregates. Each step plays a vital role in the effectiveness and durability of the final paving mixture.

Examples & Analogies

Think of dry mix design like baking a cake. Just as you need to select the right ingredients (flour, sugar, eggs) and determine how much of each to use for the cake to rise properly and have the right texture, mix design involves choosing the right aggregates and proportioning them to create a stable and durable surface.

Selection of Aggregates

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The desirable qualities of a bituminous paving mixture are dependent to a considerable degree on the nature of the aggregates used. Aggregates are classified as coarse, fine, and filler. The function of the coarse aggregates in contributing to the stability of a bituminous paving mixture is largely due to interlocking and frictional resistance of adjacent particles. Similarly, fines or sand contributes to stability failure function in filling the voids between coarse aggregates. Mineral filler is largely visualized as a void filling agent. Crushed aggregates and sharp sands produce higher stability of the mix when compared with gravel and rounded sands.

Detailed Explanation

Selecting the right aggregates is essential because their properties directly influence the performance of the paving mixture. Aggregates are divided into three categories: coarse aggregates, which provide structural support through their size and shape; fine aggregates, which fill gaps between coarse aggregates and help provide stability; and fillers, which further minimize voids. Coarse aggregates interlock and create friction, enhancing the mixture's stability, while finer materials improve compactness. Crushed aggregates and sharp sands are generally preferred over rounded materials as they enhance the overall stability of the mix due to better interlocking.

Examples & Analogies

Consider building a sandcastle at the beach. Using coarse sand (like small pebbles) at the base provides a sturdy foundation, while fine sand fills the gaps, making the structure stable. If you only had rounded beach sand, your castle might collapse easily because it wouldn't hold its shape well.

Aggregate Gradation

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

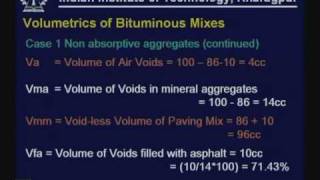

The properties of the bituminous mix including the density and stability are very much dependent on the aggregates and their grain size distribution. Gradation has a profound effect on mix performance. It might be reasonable to believe that the best gradation is one that produces maximum density. This would involve a particle arrangement where smaller particles are packed between larger particles, thus reducing the void space between particles. This creates more particle-to-particle contact, which in bituminous pavements would increase stability and reduce water infiltration.

Detailed Explanation

Aggregate gradation refers to how different sizes of aggregates are mixed together. Proper gradation optimizes the arrangement of aggregates, allowing smaller particles to fit in the spaces between larger ones. This close packing reduces voids and maximizes density, which enhances the paving mix's stability and helps prevent water infiltration. However, having some void space is important to allow the binder to fill gaps, facilitate drainage, and resist frost action in foundation layers.

Examples & Analogies

Imagine loading a box with balls of various sizes. If you have just big balls, there's a lot of empty space. If you add smaller balls, they fill the gaps and reduce the empty space, making the box denser and harder to crush. Similarly, well-graded aggregates enhance the density and overall strength of the paving mixture.

Proportioning of Aggregates

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

After selecting the aggregates and their gradation, proportioning of aggregates has to be done and following are the common methods of proportioning of aggregates: 1. Trial and error procedure: Vary the proportion of materials until the required aggregate gradation is achieved. 2. Graphical Methods: Two graphical methods in common use for proportioning of aggregates are, Triangular chart method and Rothfuch’s method. The former is used when only three materials are to be mixed. 3. Analytical Method: In this method, a system of equations are developed based on the gradation of each aggregate, required gradation, and solved by numerical methods.

Detailed Explanation

Once the appropriate aggregates and their sizes are selected, the next step is proportioning them accurately to achieve the desired gradation. There are several methods for this: the trial and error approach, which involves adjusting the proportions until the target gradation is hit; graphical methods, commonly the triangular chart and Rothfuch’s method, used for mixing three materials; and the analytical method, where mathematical equations are formulated based on the gradation needs and then solved, traditionally done with computer software now for efficiency.

Examples & Analogies

Imagine mixing ingredients for a custom smoothie. You might start with some fruits, test different amounts, and see how it tastes until you reach your perfect mix. This is similar to the trial and error method in proportioning aggregates to achieve the desired balance in the paving mix. Using a recipe (or equations) can help ensure you get that perfect flavor balance every time.

Key Concepts

-

Objective of Dry Mix Design: The main goal is to optimize the proportion of mineral aggregates to achieve maximum density.

-

Selection of Aggregates: It includes choosing the right type of aggregates based on their size and properties.

-

Importance of Gradation: Proper gradation ensures optimal packing and improves the mix stability.

-

Proportioning Methods: Common methods include trial and error, graphical methods, and analytical methods.

Examples & Applications

An example of selecting aggregates is choosing crushed stones for coarse aggregate for better interlocking.

An example of using Fuller’s Law in practical gradation calculation to maximize density in asphalt mixtures.

Flash Cards

Glossary

- Aggregates

Materials such as gravel, sand, and crushed stones used in concrete and asphalt mixtures.

- Gradation

The distribution of different particle sizes in a particular mixture.

- Bituminous Mixture

A mixture that involves bitumen, a sticky substance derived from petroleum, combined with aggregates.

- Proportioning

The process of determining the right amounts of various components in a mixture.

- Fuller’s Law

A principle that describes the optimal grading of aggregates for maximum density.

Reference links

Supplementary resources to enhance your learning experience.