Flexible pavement design

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Overview of Flexible Pavements

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're diving into flexible pavement design, which gets its name from the ability of the pavement structure to flex under the loads applied. Each layer of material spreads the load from above to the layers beneath. Can anyone tell me why it's essential to arrange these layers by load-bearing capacity?

I think it's so that the top layers can handle more stress since they're exposed to heavier loads!

Exactly! We want the most robust, expensive materials at the top, gradually decreasing in load capacity down to the subgrade. This helps in managing stress efficiently.

How does this layering actually reduce stress on the subgrade?

Great question! By distributing the loads through multiple layers, the maximum stress is concentrated on the top layer but significantly decreases at the subgrade, minimizing potential failure.

Design Procedures

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's move on to the design procedures. What do you think distinguishes empirical design from mechanistic-empirical design?

I believe empirical design relies on past data, while mechanistic-empirical considers both mechanics and historical data.

Exactly right! Empirical design uses historical experiences, while mechanistic-empirical integrates those experiences with a mechanical understanding of material behavior under load.

Can we talk about the materials involved?

Certainly! The properties of materials, such as their elasticity and resilient modulus, play a crucial role in determining layer thickness and performance.

Traffic and Loading Considerations

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Traffic loading is vital in our design. Can someone explain the difference between fixed traffic and variable traffic approaches?

In fixed traffic, we only consider the maximum load, right?

Correct! Fixed traffic doesn’t account for load repetitions. In contrast, variable traffic allows us to analyze impacts from various load groups separately.

How do we determine the Equivalent Single Wheel Load?

Excellent question! The ESWL is derived from specific formulas that equate the pressure exerted by dual wheels to a single wheel load, allowing for a more straightforward evaluation of stresses.

Material Characterization and Testing

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, we need to understand material behavior in detail. Who can explain the concept of resilient modulus?

Isn't it the measure of how much strain is recoverable under repeated loads?

Perfect! The resilient modulus provides insight into how pavement materials will respond over time. Let's also touch on dynamic complex modulus. How does that differ?

It relates to sinusoidal loading and characterizes visco-elastic behavior, right?

Exactly! Different loading conditions affect the modulus, and selecting appropriate test conditions is crucial.

Conclusion and Mechanistic-Empirical Analysis

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let’s summarize what we learned. What are the key advantages of using mechanistic-empirical design?

It provides more reliable performance predictions and accommodates different materials?

Exactly! It enhances our ability to adapt to varying conditions and materials used in pavement construction.

Can you give us a real-world example of using these principles?

Absolutely! Real addresses and highways benefit from the mechanistic-empirical approach by improving their longevity under heavy traffic loads.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section discusses the principles and methods of flexible pavement design, highlighting its structure, design procedures, traffic loading considerations, and the importance of mechanistic-empirical analysis in determining layer thickness and material properties.

Detailed

Detailed Summary

Flexible pavements are characterized by their ability to deflect under loads, forming a structure with multiple layers that effectively manage stress. The loads from traffic are distributed through these layers, reducing the maximum stress on the subgrade. The design of flexible pavements focuses on determining the appropriate thickness and material composition of these layers, taking into account stresses arising from traffic and temperature changes.

Two primary design methods are employed: Empirical Design, which relies on historical data and soil classification systems (e.g., HRB classification and CBR tests), and Mechanistic-Empirical Design, which integrates both mechanical principles and empirical relationships to predict pavement behavior under load.

This section also addresses the factors related to traffic and loading, including fixed traffic, fixed vehicle loads, and variable traffic conditions which dictate the pavement's design. Understanding the concept of the Equivalent Single Wheel Load (ESWL) is crucial in determining the loads affecting pavement structures.

The pavement's material characteristics and behavior, including the concepts of resilient modulus and dynamic complex modulus, are also detailed to highlight their significance in the design process. Mechanistic-Empirical analysis provides a comprehensive approach to pavement design, accommodating various material properties and environmental effects, ultimately yielding more reliable performance predictions.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Overview of Flexible Pavements

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

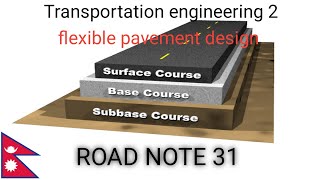

Flexible pavements are so named because the total pavement structure deects, or exes, under loading. A exible pavement structure is typically composed of several layers of materials. Each layer receives loads from the above layer, spreads them out, and passes on these loads to the next layer below. Thus the stresses will be reduced, which are maximum at the top layer and minimum on the top of the subgrade. In order to take maximum advantage of this property, layers are usually arranged in the order of descending load bearing capacity with the highest load bearing capacity material (and most expensive) on the top and the lowest load bearing capacity material (and least expensive) on the bottom.

Detailed Explanation

Flexible pavements are designed to flex under heavy loads, which helps distribute weight and reduce stress on the lower layers of the pavement and the underlying soil (subgrade). This concept is crucial for maximizing the lifespan and performance of a road. The top layer, made of more expensive, stronger materials, handles the most significant stresses because it carries the weight of vehicles directly. Beneath it, layers become progressively less capable of bearing loads, allowing for an economical design where not all layers require the same level of strength and durability.

Examples & Analogies

Think of flexible pavement like a cushion made of layers of soft and firm foam. The top layer is firm to handle the initial impact when someone sits on it, while the layers below can be softer to provide comfort. Just like the firm cushion distributes weight evenly, flexible pavements ensure that the load from vehicles is distributed through its layers to prevent any single layer from failing.

Design Procedures for Flexible Pavements

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

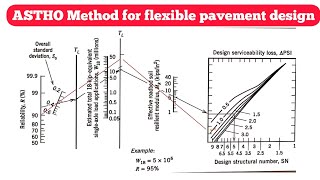

For flexible pavements, structural design is mainly concerned with determining appropriate layer thickness and composition. The main design factors are stresses due to traffic load and temperature variations. Two methods of flexible pavement structural design are common today: Empirical design and mechanistic empirical design.

Detailed Explanation

The design of flexible pavements focuses on how thick each layer should be and what materials should be used. Two main approaches exist: empirical design, based on past data and observed experiences, and mechanistic empirical design, which combines mechanical principles with empirical data to better predict performance under varying conditions. This ensures that the pavement can withstand the stresses from traffic and temperature changes over time.

Examples & Analogies

Designing a flexible pavement can be likened to baking a cake. Just as a baker must decide how thick each layer of cake should be and what ingredients to use based on past baking experiences, engineers must carefully select layer thickness and materials based on historical data and mechanical principles to create a durable and functional pavement.

Empirical Design Method

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

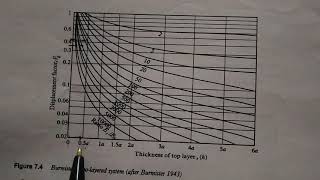

An empirical approach is one which is based on the results of experimentation or experience. Some of them are either based on physical properties or strength parameters of soil subgrade. An empirical analysis of flexible pavement design can be done with or without a soil strength test. An example of design without soil strength test is by using the HRB soil classification system, in which soils are grouped from A-1 to A-7 and a group index is added to differentiate soils within each group.

Detailed Explanation

The empirical design method relies on previously gathered data and experiences to inform design choices. It can involve direct measurements, like soil strength tests, or use classification systems that categorize soil types without detailed analysis. This approach allows engineers to quickly utilize past findings to inform current projects, potentially speeding up the design process and ensuring tried-and-true methods are employed.

Examples & Analogies

Using empirical design for pavement is like following a well-tested recipe when cooking. If a chef knows from experience that a particular combination of ingredients works well, they might not experiment every time but instead rely on that established recipe to ensure success.

Mechanistic-Empirical Design Method

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The Empirical-Mechanistic method of design is based on the mechanics of materials that relate input, such as wheel load, to an output or pavement response. In pavement design, the responses are the stresses, strains, and deflections within a pavement structure and the physical causes are the loads and material properties of the pavement structure.

Detailed Explanation

The mechanistic-empirical design method combines calculations from mechanical principles with empirical data. It assesses how pavement will respond to specific loads and conditions, such as how much stress and deformation will occur within the layers. This model helps in better predicting pavement performance over time, considering the real physical effects of traffic loads and environmental conditions.

Examples & Analogies

This design approach is analogous to a car's suspension system engineering. Engineers calculate how the suspension components will handle various weights and driving conditions to ensure the car rides smoothly. Likewise, the mechanistic-empirical method allows pavement engineers to predict how stresses will affect roads under real-world conditions.

Key Concepts

-

Flexible Pavement: A pavement that bends under load.

-

Layered Structure: Multiple layers to distribute loads efficiently.

-

Empirical Design: Relies on historical data and experiments.

-

Mechanistic-Empirical Design: Combines mechanics and empirical data.

-

Traffic Loading: Various loading conditions influence pavement design.

Examples & Applications

An urban highway uses mechanistic-empirical design principles to ensure durability under high traffic.

A local road is designed using empirical methods based on soil classifications to predict long-term performance.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Layers of pavement, strong as a gate, each with load-bearing, just right for weight.

Stories

Imagine a group of friends - each layer of pavement - working together to carry a load without collapsing, just like companions sharing a heavier backpack.

Memory Tools

Remember: L.E.M.E - Layers, Empirical methods, Mechanistic principles, Equivalent loads.

Acronyms

P.L.E.A.S.E - Pavement Layers Evenly At Stress Equilibrium.

Flash Cards

Glossary

- Flexible Pavement

A type of pavement that deforms under load due to its layered structure.

- Empirical Design

A design method based on historical data and experimental results.

- MechanisticEmpirical Design

A design methodology combining mechanics and empirical relationships to predict pavement behavior.

- Equivalent Single Wheel Load (ESWL)

A single wheel load that exerts the same contact pressure as a dual wheel assembly.

- Resilient Modulus

A measure of a material's elasticity as it relates to recoverable strain under repeated loads.

- Dynamic Complex Modulus

The elasticity measure of visco-elastic materials under sinusoidal loading conditions.

Reference links

Supplementary resources to enhance your learning experience.