Pavement materials: Aggregates

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Overview of Aggregates

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're discussing aggregates, which are essential for creating pavement materials. Can anyone tell me what aggregates consist of?

Are they just rocks and sand?

Exactly! Aggregates include materials like sand, gravel, and crushed stone. They can be natural or manufactured. Who remembers the percentage of aggregates in bituminous and Portland cement concrete?

Bituminous concrete has 92 to 96 percent, and Portland cement concrete has 70 to 80 percent!

Great job! Remember, aggregates play a huge role in the stability and longevity of our pavements.

Desirable Properties of Aggregates

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's dive into the desirable properties of aggregates. What qualities do you think are important for aggregates in pavements?

I think they should be strong enough to hold up under traffic.

Correct! Strength, hardness, and toughness are crucial properties. For example, aggregates need high resistance to crushing. Who can tell me why hardness matters?

Hardness is important so they can resist wear from traffic!

Exactly! Let's not forget about durability and adhesion with bitumen, which can affect how well the asphalt bonds. Think of a memory aid for these properties; how about 'STHDA' for Strength, Toughness, Hardness, Durability, and Adhesion?

Testing of Aggregates

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s talk about the various tests performed to evaluate aggregates. Can anyone name one?

The crushing test?

Correct! The crushing test measures the aggregate's strength. What are some other tests we need to be aware of?

There’s the abrasion test and the impact test!

Yes! The abrasion test assesses hardness, while the impact test gives us insight into an aggregate's toughness. Who can explain why these tests are important?

They help ensure that the aggregates we use are suitable for pavement construction and can withstand traffic conditions.

Exactly, well done!

Quality Standards for Aggregates

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let’s address quality standards for aggregates. What types of materials should aggregates be free from?

They should be free from dirt, clay, and other undesirable materials.

Exactly! Excessive flaky or elongated particles can compromise the strength and durability. Who remembers the role of adhesion with bitumen?

If they have too much water affinity, the bitumen can strip away, reducing the pavement quality.

Well said! Proper aggregate quality is key to sustainable and durable pavements. Remember this information for your future discussions!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Aggregates are crucial materials in pavement construction, comprising the bulk of composites like bituminous and Portland cement concretes. This section outlines their desirable properties, such as strength and hardiness, the need for specific tests to evaluate their suitability, and their impact on pavement performance.

Detailed

Detailed Summary

Aggregates are materials like sand, gravel, and crushed stone that serve as the primary constituents in pavement construction, forming a significant portion of both bituminous concrete (92-96%) and Portland cement concrete (70-80%). They may be natural or manufactured and are chosen for their various properties, including strength, hardness, toughness, shape, adhesion with bitumen, durability, and freedom from deleterious materials. Specific tests are mandated to ascertain these properties, including the crushing, abrasion, impact, soundness, shape, specific gravity, and bitumen adhesion tests. Understanding these qualities and their testing ensures that aggregates meet the necessary performance standards in pavement systems.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Overview of Aggregates

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Aggregate is a collective term for the mineral materials such as sand, gravel, and crushed stone that are used with a binding medium (such as water, bitumen, Portland cement, lime, etc.) to form compound materials (such as bituminous concrete and Portland cement concrete). By volume, aggregate generally accounts for 92 to 96 percent of Bituminous concrete and about 70 to 80 percent of Portland cement concrete. Aggregate is also used for base and sub-base courses for both flexible and rigid pavements. Aggregates can either be natural or manufactured. Natural aggregates are generally extracted from larger rock formations through an open excavation (quarry). Extracted rock is typically reduced to usable sizes by mechanical crushing. Manufactured aggregate is often a byproduct of other manufacturing industries. The requirements of the aggregates in pavement are also discussed in this chapter.

Detailed Explanation

This section defines what aggregates are and their significance in pavement materials. Aggregates are essentially raw materials like sand and gravel that are combined with binding agents to create concrete. They make up a large portion of concrete mixtures, providing strength and stability. There are two types of aggregates: natural aggregates, which come from quarries, and manufactured aggregates, which are byproducts from other processes. Finally, this section emphasizes the importance of aggregates in both flexible and rigid pavement construction.

Examples & Analogies

Think of aggregates like building blocks in a structure. Just like a house needs bricks or blocks to stand strong, pavements require aggregates to ensure they hold up under traffic. Without these key elements, the pavement would crumble and become unusable.

Desirable Properties of Aggregates

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The aggregates used in top layers are subjected to (i) Stress action due to traffic wheel load, (ii) Wear and tear, (iii) Crushing. For a high-quality pavement, the aggregates should possess high resistance to crushing, and to withstand the stresses due to traffic wheel load.

Detailed Explanation

Aggregates need to be strong to cope with the pressures exerted by vehicles driving over them. The section outlines how aggregates face stress from the weight of traffic, wear from movement, and crushing from pressure. Therefore, choosing aggregates with high strength helps ensure the durability and longevity of pavements.

Examples & Analogies

Imagine the wear and tear on the ground where you park your car. Over time, the constant weight can cause the surface to crack or degrade. If you use strong and durable materials, like concrete made with tough aggregates, the surface will last much longer, just like using high-quality tires on a vehicle ensures their longevity.

Importance of Aggregate Shape

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Aggregates which happen to fall in a particular size range may have rounded, cubical, angular, flaky or elongated particles. It is evident that the flaky and elongated particles will have less strength and durability when compared with cubical, angular, or rounded particles of the same aggregate. Hence too flaky and too much elongated aggregates should be avoided as far as possible.

Detailed Explanation

The shape of aggregates plays a crucial role in determining the strength and durability of the pavement. Aggregates that are flaky or elongated can create weaker pavements compared to those that are cubical or rounded, which interlock better to resist movement and deterioration. Therefore, it is essential to select appropriate shapes for optimal pavement performance.

Examples & Analogies

Picture trying to build a stable structure with playing blocks. If you use irregularly shaped ones, like long and thin pieces, they might not stack well or hold together. However, if you use blocks that fit together nicely, like cubes, the structure will be much more stable and stronger—just like quality aggregates help build durable pavements.

Adhesion with Bitumen

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The aggregates used in bituminous pavements should have less affinity with water when compared with bituminous materials, otherwise, the bituminous coating on the aggregate will be stripped off in presence of water.

Detailed Explanation

In pavements where bitumen is used as a binder, aggregates must be chosen carefully based on their interaction with water. If aggregates attract too much water, the bitumen won't adhere properly, leading to degradation and failure of the pavement. Thus, selecting aggregates with appropriate affinity for water ensures that the bituminous coating remains intact.

Examples & Analogies

Think of it like spreading butter on toast. If the toast is wet, the butter won’t stick well, right? Similarly, if aggregates are too water-friendly, they won't hold onto the bitumen well, creating weak points in the pavement.

Testing Aggregates for Quality

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

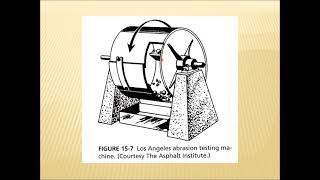

In order to decide the suitability of the aggregate for use in pavement construction, following tests are carried out: Crushing test, Abrasion test, Impact test, Soundness test, Shape test, Specific gravity and water absorption test, Bitumen adhesion test.

Detailed Explanation

Before using aggregates in pavement construction, several standardized tests are performed to ensure their quality. Each test evaluates different properties such as strength, hardness, and adhesion to bitumen. This testing process helps guarantee that only the best materials are used in pavements, ultimately affecting their durability and performance.

Examples & Analogies

Just as a chef tastes ingredients before cooking to ensure they are fresh and suitable for the dish, engineers test aggregates to confirm they meet the necessary standards for pavement construction.

Key Concepts

-

Aggregates: Primary constituent materials in pavement.

-

Strength: Resistance to crushing under traffic load.

-

Hardness: Ability to resist wear due to traffic movement.

-

Toughness: Resistance to impact from vehicle wheels.

-

Durability: Ability to withstand weathering and degradation.

-

Shape: Influence of particle shape on aggregate performance.

-

Adhesion: Importance of water affinity in bituminous pavements.

Examples & Applications

Natural aggregates like river stones are often used due to their rounded shape, which improves workability.

Manufactured aggregates, such as those produced from recycled concrete, can offer both sustainability and suitable performance characteristics.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Aggregates, they are tall and strong, for pavements where they belong.

Stories

Once, in a land of pavements, aggregates knew they held the strength to support the roads beneath heavy loads, enduring seasons and speeding cars.

Memory Tools

Remember STHDA for the properties: Strength, Toughness, Hardness, Durability, Adhesion.

Acronyms

HASTED - Hardness, Adherence, Strength, Toughness, Endurance, Durability.

Flash Cards

Glossary

- Aggregates

Mineral materials such as sand, gravel, and crushed stone used in construction.

- Bitumen

A binding medium used in asphalt pavements, typically derived from petroleum.

- Durability

The ability of materials to resist wear and deterioration over time.

- Toughness

The ability of a material to absorb energy and deform without breaking.

- Adhesion

The attraction between the surfaces of two different materials, such as aggregates and bitumen.

- Crushing Test

A test that determines the crushing strength of aggregates under load.

- Abrasion Test

A test that evaluates the hardness and wear-resistance of aggregates.

- Impact Test

A test that assesses the resistance of aggregates to sudden impact.

Reference links

Supplementary resources to enhance your learning experience.