Pavement materials: Bitumen

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Overview of Bitumen

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's start our discussion with the overview of bitumen. Can anyone tell me what role bitumen plays in pavement construction?

Bitumen is used to bind the materials used to make roads, right?

Exactly, Student_1! Bitumen is a viscous material that has excellent adhesive properties and is resistant to water, making it ideal for road construction. Can anyone tell me what bitumen is mainly derived from?

It's derived from the distillation of petroleum, I believe.

Correct! This is significant because its properties can vary based on how it's processed. Remember that bitumen is defined by its high molecular weight hydrocarbons. Let's remember that as 'Big High H' - 'Bitumen Is Great High Hydrocarbon'! Now, why do you think its waterproof nature is an advantage?

It helps prevent water damage to the road surface, right?

Very good! Proper waterproofing enhances the longevity of the roads. In summary, bitumen's binding and waterproofing properties make it a preferred choice for pavement materials.

Production of Bitumen

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, let's dive into the various methods used to produce bitumen. Who can share how bitumen is typically produced?

Is it mainly from refining crude oil?

That's right! It’s a by-product of refining crude petroleum. One particular process used is vacuum-steam distillation. What can you tell me about why steam is used in this process?

I think it's to minimize the breakdown of the petroleum components during heating.

Exactly! By using steam, we reduce the risk of decomposing valuable components. Now remember the acronym 'VIP' - Vagueness Is Prevented by steam. This will help you recall the significance of steam in this process. Can anyone explain what happens to the residue once distillation is complete?

It's fed into the vacuum distillation unit to separate heavier gas oils from the bitumen.

Perfectly said! This helps us control the consistency of the asphalt. Great work, everyone!

Different Forms of Bitumen

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's discuss the different forms of bitumen. Can anyone name a type of liquid binder used during colder weather?

Cutback bitumen!

Correct! Cutback bitumen is used when we need to lower its viscosity. Can someone tell me what kinds of solvents are used in it?

Naphtha, kerosene, and diesel oil are some of them.

Yes! Now, remember, we categorize these solvents based on how quick they evaporate. With this in mind, let's use the acronym 'RMC' - Rapid, Medium, and Slow curing to recall types of cutback bitumen. What are the applications for each type?

RC is for surface dressing, MC is for premixing with less fine aggregates, and SC is for more fine aggregates in the mix.

Exactly! Each has its specific application based on temperature and moisture conditions. Great summary, class!

Testing of Bitumen

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, we will examine the tests performed on bitumen. What is the main purpose of conducting these tests?

To evaluate its consistency and suitability for use in pavement?

Perfectly said! The penetration test, for instance, determines the hardness of bitumen. Can someone explain how it works?

It uses a weighted needle that penetrates the sample at a specific temperature.

Great job! Remember 'PNP' - Penetration Needs Precision; the specific temperature is crucial for accurate results. What about the ductility test? What does it measure?

It measures how much the bitumen can stretch before breaking.

Exactly! This property is vital for accommodating roadway movements and temperature fluctuations. Summarizing, knowing these tests helps ensure the safety and efficiency of paving materials.

Advantages of Modified Bitumen

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let's talk about modified bitumen. Can anyone explain what it is?

It's bitumen that has had additives mixed in to improve its properties!

Exactly! Additives can increase flexibility and resistance to temperature changes. Can someone share some advantages of using modified bitumen?

It has lower susceptibility to temperature changes and better adhesion!

Correct! These properties help prevent aging and cracking. Let's create a phrase to recall this: 'More Flexibility, More Strength' to make it catchy. What implications does this have for pavement longevity?

It means the roads would last longer and remain safe under extreme weather conditions.

Well said! Modified bitumen indeed contributes significantly to the durability of pavements. Great class today, everyone!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section provides an overview of asphalt and bituminous materials in pavement construction, detailing the production methods, forms of bitumen such as cutback and emulsion, requirements, testing methods, and their advantages in road surface applications.

Detailed

Detailed Summary

Bituminous materials are crucial in roadway construction due to their excellent binding and waterproofing properties, making them both effective and cost-efficient. The primary component of these materials, bitumen, is a viscous substance derived from petroleum distillation. The section goes on to explain the production of bitumen through various refinery processes, including vacuum-steam distillation, which aids in managing the viscosity and properties of the asphalt produced. Different forms of bitumen are discussed, along with their applications. For example, cutback bitumen, which uses solvents to adjust viscosity, is employed in colder climates, while bitumen emulsions are useful for specific structural applications. Additionally, modified bitumen incorporates additives to enhance performance, exhibiting benefits like improved temperature resistance and adhesion.

The section also lists essential properties that bitumen must possess, including temperature stability and sufficient viscosity during mixing. Various tests to evaluate bituminous materials are outlined, such as penetration, ductility, and viscosity tests, integral to assessing their physical characteristics. The importance of understanding these properties helps in selecting suitable materials for effective and long-lasting pavement construction.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Overview of Bitumen

Chapter 1 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Bituminous materials or asphalts are extensively used for roadway construction, primarily because of their excellent binding characteristics and water-proofing properties and relatively low cost. Bituminous materials consist of bitumen, which is a black or dark coloured solid or viscous cementitious substance, consisting chiefly of high molecular weight hydrocarbons derived from the distillation of petroleum or natural asphalt, has adhesive properties, and is soluble in carbon disulphide.

Detailed Explanation

Bitumen is a vital material used in making roads because it effectively holds aggregates together and prevents water from damaging the road structure. It's a viscous substance derived mostly from oil, which gives it strong adhesive qualities. This means when heated, bitumen becomes liquid and can bind materials like gravel and sand together. Once cooled, it forms a solid and durable structure. Its characteristics make it suitable for various climatic conditions, and because it is a by-product of petroleum refinement, it is relatively inexpensive.

Examples & Analogies

Think of bitumen like honey. When you heat honey, it flows easily and can stick to items you dip in it. Once cooled, it becomes thick and holds the items together tightly. Similarly, when bitumen is heated, it binds road materials together to create a stable surface.

Production of Bitumen

Chapter 2 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Bitumen is the residue or by-product when crude petroleum is refined. A wide variety of refinery processes, such as the straight distillation process and solvent extraction process, may be used to produce bitumen with different consistency and other desirable properties.

Detailed Explanation

The production of bitumen starts with crude oil, which undergoes various refining processes. During refining, different techniques are applied to separate components of crude oil. The remainder, which does not evaporate, is bitumen. This shows bitumen is not just a simple by-product; its properties can be adjusted based on how it's processed. Factors like the source of crude oil and the specific needs for construction determine the methods used in production.

Examples & Analogies

Imagine making syrup from maple sap. You boil the sap down to separate the liquid from the solid; what's left is thicker and can vary in flavor depending on how you boil it. Similarly, the method of refining crude oil defines the quantity and quality of bitumen produced.

Vacuum Steam Distillation Process

Chapter 3 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

In the vacuum-steam distillation process, crude oil is heated and introduced into a large cylindrical still. Steam is introduced to aid in vaporization of more volatile constituents of petroleum and to minimize the decomposition of the distillates and residues.

Detailed Explanation

This process is crucial for obtaining high-quality bitumen. By reducing pressure and adding steam, it allows for the separation of lighter fractions without breaking down the heavier ones. When the crude oil is heated, it eventually separates into different components, and the remaining residue contains the bitumen. The method's careful temperature control ensures the end product meets specific requirements for construction.

Examples & Analogies

Consider how food cooks in a low-pressure environment, like a pressure cooker. The low pressure speeds up the cooking process without losing the flavors and nutrients. In a similar way, vacuum steam distillation efficiently extracts useful compounds from crude oil.

Different Forms of Bitumen

Chapter 4 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

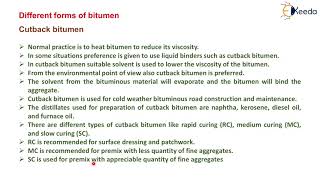

There are various forms of bitumen, including cutback bitumen, bitumen emulsion, bituminous primers, and modified bitumen. Each type is designed for different applications and pays attention to the specific needs of pavement construction.

Detailed Explanation

- Cutback Bitumen: Used to reduce viscosity for cold-weather applications. It is mixed with solvents like kerosene, which evaporate after application. Different curing types (RC, MC, SC) address varied conditions.

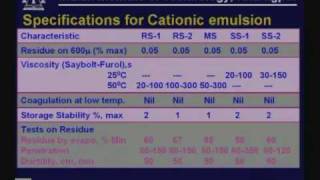

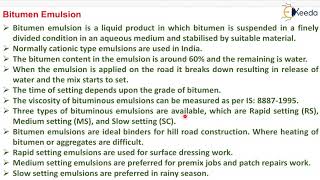

- Bitumen Emulsion: A mixture of bitumen and water, also stabilized by other materials; it breaks down when spread on roads.

- Bituminous Primers: Improve adhesion on the surface before applying asphalt layers.

- Modified Bitumen: Enhances performance with additives for high-stress conditions or extreme weather. Understanding these forms is key to using them effectively in road construction.

Examples & Analogies

Consider making a cake with different frosting options. For different kinds of cakes, you might prefer buttercream for rich flavors, whipped cream for a light texture, or fondant for a smoother finish. Similarly, the choice of bitumen form depends on the road conditions and required durability.

Requirements of Bitumen

Chapter 5 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

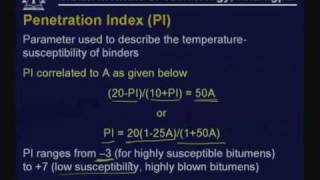

The desirable properties of bitumen depend on the mix type and construction. Generally, bitumen should not be highly temperature susceptible and should have adequate viscosity. There should also be adequate affinity and adhesion between bitumen and aggregates used in the mix.

Detailed Explanation

Bitumen should remain stable under varying temperatures—it shouldn't become too soft in the heat or too hard in the cold. The viscosity at mixing time is essential because it affects how well it binds with aggregates. This ensures a durable mixture that can withstand stresses over time. Proper adhesion between bitumen and aggregates is equally important for the longevity of the pavement.

Examples & Analogies

Think about how a good glue works: if it’s too thick, it won’t spread well; if it’s too watery, it won’t stick. Just like this, bitumen must have the right viscosity to ensure proper bonding with road materials to create a strong and durable surface.

Tests on Bitumen

Chapter 6 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Various tests, like the penetration test, ductility test, softening point test, specific gravity test, viscosity test, flash and fire point test, and others, assess the properties of bituminous materials.

Detailed Explanation

Multiple tests are conducted to evaluate different characteristics of bitumen: 1. Penetration test measures hardness or softness. 2. Ductility test assesses tensile properties and flexibility. 3. Softening point test measures temperature stability. 4. Viscosity test determines flow characteristics. 5. Flash and Fire point tests indicate safety levels. These tests are crucial in ensuring that bitumen meets required standards for pavement construction, and specific methods are linked to Indian Standards (IS).

Examples & Analogies

Think of these tests like a diagnostic checkup for your car. Each test checks a different part of the car's running condition, ensuring that everything is functioning correctly. Without these tests, you wouldn’t know if your car can handle a long drive safely, just as roads need verified materials to ensure their durability and safety.

Summary of Bitumen Properties and Testing

Chapter 7 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Requirements of bitumen as a binding material and its different forms were discussed. Various tests are conducted on bitumen to assess its consistency, gradation, viscosity, temperature susceptibility, and safety.

Detailed Explanation

This section concludes that understanding bitumen's properties, including its various forms and testing methods, is crucial for successful road construction. Each form serves specific applications depending on road conditions, and the tests ensure that the material meets necessary performance standards.

Examples & Analogies

Imagine preparing for a big exam. You need to know your subjects well (properties of bitumen) and should also practice different types of questions (testing methods). Just as preparation ensures your success in exams, comprehensive knowledge of bitumen guarantees reliable performance of roads.

Key Concepts

-

Bitumen: A key material in road construction with binding and waterproofing properties.

-

Cutback Bitumen: Used for reducing viscosity and facilitating application in colder conditions.

-

Bitumen Emulsion: A form of bitumen suspended in water, used in wet conditions.

-

Ductility: Indicates flexibility under stress, crucial for effective road materials.

-

Penetration Test: A method for assessing bitumen hardness and suitability.

Examples & Applications

Bitumen is used for sealing cracks in asphalt pavements to prevent water penetration.

Cutback bitumen is utilized in cold weather to enable paving without heating the asphalt.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

In roads we lay, bitumen's the way, binding the gravel, come what may!

Stories

Once a liquid gold, bitumen was found, it flows in the heat, and fills up each round. With additives mixed and tested in schools, it built up the roads, defying all rules.

Memory Tools

B.E.C.D - Bitumen Emulsion, Cutback, Ductility to remember key types of bitumen and their applications.

Acronyms

RMC

Rapid

Medium

and Slow curing helps remember types of cutback bitumen!

Flash Cards

Glossary

- Bitumen

A viscous substance consisting chiefly of high molecular weight hydrocarbons derived from petroleum distillation, used as a binder in pavement.

- Cutback Bitumen

Bitumen mixed with a solvent to lower its viscosity and facilitate application at lower temperatures.

- Bitumen Emulsion

A liquid product where bitumen is suspended in water, commonly used in pavement construction.

- Ductility

The ability of bitumen to deform under tensile stress without breaking.

- Penetration Test

A test measuring the hardness of bitumen by determining how deep a standard needle penetrates in 5 seconds.

Reference links

Supplementary resources to enhance your learning experience.