Stereolithography (SLA)

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Stereolithography (SLA)

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we will dive into Stereolithography, or SLA. It's a fascinating process that shapes 3D models using photopolymer resin. Can anyone tell me what additive manufacturing means?

Additive manufacturing is when you build objects layer by layer, instead of cutting them out from a solid material.

Exactly! In SLA, we slice a 3D CAD model into layers and use a UV laser to solidify these layers. It allows us to create complex designs. What's one advantage of using SLA?

I think it can create very detailed shapes quickly.

Correct! SLA is known for excellent surface quality and speed, especially in prototyping. However, what do we need to do after printing?

We need to wash off the resin and do some curing, right?

Correct! Post-processing is essential to enhance strength and usability of printed models.

In summary, SLA is a powerful tool in additive manufacturing that enables intricate designs through layer-by-layer construction.

The Process of Stereolithography

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s talk about how SLA actually works. Who can explain the basic steps in the SLA process?

First, you start with a 3D model, and then it’s sliced into layers. After that, a laser cures the resin layer by layer.

Great! Each layer is cured along precise paths, allowing us to create fine details. What can you say about the thickness of these layers?

They usually range from 25 to 100 microns, right?

Exactly! And in advanced systems, we can even get down to a few microns! Why is this thickness important?

Thinner layers help achieve smoother surfaces and more detailed features!

Spot on! That’s why SLA can create intricate designs. Let’s recall these key points: Layer slicing, UV laser curing, and layer thickness.

Materials Used in SLA

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s shift our focus to the photopolymers used in SLA. What do you know about them?

They are liquid resins that harden when exposed to UV light.

Absolutely! These photopolymers consist of monomers, oligomers, and photoinitiators. How do these components contribute to the final properties of the printed objects?

The mix of those chemicals affects the strength, flexibility, and curing speed of the resin.

Right! And this means we can tailor properties to fit specific applications. Can anyone give an example of where SLA's versatility shines?

In creating dental devices or jewelry prototypes!

Perfect examples! To sum it up, the choice of photopolymer influences both the quality and application of SLA-produced parts significantly.

Applications and Challenges of SLA

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let's consider the applications and challenges of SLA. What are some uses for this technology?

It's used for rapid prototyping and making custom medical devices!

Exactly! SLA is extensively used in the dental field, jewelry design, and even in microfluidics. But what are the challenges we should be aware of?

We need to deal with post-processing, and the parts can be brittle.

That's correct. Also, photopolymer resins are often expensive and may degrade under certain conditions. To summarize today, SLA has exciting applications but comes with notable challenges.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

SLA, a form of vat photopolymerization, constructs 3D models by selectively curing liquid resin with a UV laser in thin cross-sections. This layer-by-layer approach allows for intricate designs but necessitates post-processing and can lead to certain material limitations.

Detailed

Stereolithography (SLA)

Stereolithography (SLA) is a prominent additive manufacturing (AM) technique leveraging vat photopolymerization. This method begins with a 3D CAD model which is divided into thin horizontal cross-sections, allowing for precise construction of complex geometries.

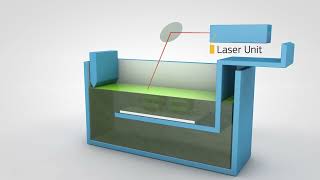

- Process Overview: Using a controlled UV laser, each layer of liquid photopolymer resin is selectively hardened along a predefined path, forming a solid shape incrementally as the build platform lowers or raises.

- After curing a layer, fresh resin covers previous layers, repeating the process until the complete model is finished.

- Post-Processing: Involves cleaning the resin and additional curing to enhance strength and usability.

- Layer Thickness: Typically ranging from 25 to 100 microns, SLA can achieve fine surface quality and complex shapes due to precise laser control.

- Photopolymers: The liquid resins used consist of monomers, oligomers, and photoinitiators that undergo photopolymerization upon exposure to UV/visible light, forming solid structures and varying in properties based on their chemical composition.

- Equipment Specifications: Common SLA machines comprise a UV laser, resin vat, and motorized platform, with build volumes varying greatly from desktop sizes to large industrial setups.

- Applications: SLA is widely used for rapid prototyping, creating precise dental devices, jewelry, and biomedical systems, offering versatility and excellent surface finish.

- Advantages and Disadvantages: With superior surface quality and rapid prototyping capabilities as advantages, challenges include the need for post-processing, material brittleness, and cost factors associated with photopolymer resins.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Overview of Stereolithography

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Stereolithography (SLA) is a vat photopolymerization-based AM technique. A 3D CAD model is sliced into thin cross-sections.

Detailed Explanation

Stereolithography, commonly referred to as SLA, is an additive manufacturing method that uses a liquid resin to build objects layer by layer. The process begins with a 3D computer-aided design (CAD) model, which is digitally sliced into very thin horizontal slices. This means that before any material is used, the digital model is prepared for the printing process by creating a outline of each layer.

Examples & Analogies

Think of SLA like making a stack of pancakes. Each pancake represents a layer of the finished product, and the batter is equivalent to the liquid resin being used. Just like you pour the batter into a pan for each pancake and stack them up, SLA adds each layer to build the final 3D object.

Layer Formation Process

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

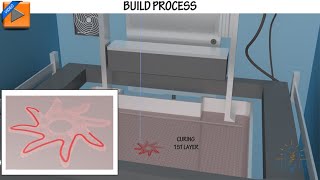

A UV laser selectively cures (solidifies) a thin layer of liquid photopolymer resin along the programmed path, forming the first layer. The build platform is incrementally lowered (or raised, depending on top-down or bottom-up configuration).

Detailed Explanation

In SLA, once the CAD model is sliced, a UV laser is used to cure the resin. This means the laser targets specific areas of the resin to solidify it into a solid part in the shape of the first layer. After one layer is completed, the build platform moves either down or up to allow a new layer of resin to cover the cured layer. This process is repeated for each layer until the entire object is fully formed.

Examples & Analogies

Imagine you're making a tower with LEGO bricks. You place one layer of bricks, and then you raise the platform to add another layer on top. Each layer of LEGOs is like the cured layer of resin that builds up to create the complete tower.

Post-Processing Steps

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Post-processing includes resin washing, support removal, and further UV curing for final solidification and handling strength.

Detailed Explanation

After the 3D object is completed, it typically requires some post-processing to achieve the desired surface finish and mechanical properties. This may involve washing away any uncured resin, removing any temporary support structures that were used during printing, and additional UV curing to enhance the strength and durability of the printed object.

Examples & Analogies

Think of baking cookies. Once they are baked, they may need cooling and some decoration (like icing or sprinkles) before they are ready to be served. Similarly, after SLA creates an object, it needs these steps to make it ready for use.

Layer Thickness and Precision

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Layers typically range from 25 to 100 microns in thickness. Fine surfaces and complex geometries are achievable due to precise laser control and small spot sizes.

Detailed Explanation

The thickness of each layer in an SLA print can vary, commonly being between 25 and 100 microns. Thinner layers can result in better detail and smoother surfaces. The precision comes from the ability to control the laser very accurately, allowing it to produce intricate designs that would be difficult to achieve with other methods.

Examples & Analogies

Imagine drawing with a fine-tipped pen versus a thick marker. The fine pen can create sharp details and thin lines that capture intricate designs, while a thick marker may not have the same level of finesse.

The Role of Photopolymers

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Photopolymers are liquid resins composed of monomers, oligomers, and photoinitiators that cure (polymerize) when exposed to UV/visible light. Photopolymerization is chemically initiated by light, turning the liquid into a solid polymer network.

Detailed Explanation

Photopolymers are specialized materials used in SLA that transform from liquid to solid upon exposure to light, specifically UV or visible light. This transformation is called photopolymerization, where light triggers a chemical reaction that bonds these liquid components, creating a solid structure. The specific properties of the final product can be manipulated by adjusting the composition of these photopolymers.

Examples & Analogies

Consider how some glues dry when exposed to light. Just like these glues turn solid under light, photopolymers harden into solid forms, making them essential for creating durable 3D models.

Key Concepts

-

Stereolithography: An additive manufacturing technique that uses UV light to cure liquid resin, creating 3D objects layer by layer.

-

Photopolymerization: The process that allows liquid photopolymers to turn into solid polymers upon exposure to light.

-

Post-Processing: The steps required after SLA printing to ensure quality, such as washing and additional curing.

Examples & Applications

Custom dental aligners that fit precisely to individual patients.

Intricate jewelry prototypes designed with fine detail using SLA.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

SLA prints with care, Layer by layer, in the air, UV cures and smoothens wide, Creating shapes that we can't hide.

Stories

Imagine a magician who turns liquid into solid with a touch of light. Each spell creates a detailed sculpture, layer by layer, until a perfect creation stands tall.

Memory Tools

Remember 'SLA' as 'Solid Layering Art' to recall the essence of Stereolithography.

Acronyms

Think of 'SLA' for 'Sculpt, Layer, Assemble' to help remember its process.

Flash Cards

Glossary

- Additive Manufacturing

A process of creating objects by layering material based on a digital model.

- Photopolymerization

A chemical process that turns liquid photopolymer into a solid through UV or visible light.

- UV Laser

A laser that emits ultraviolet light, used to cure photopolymer resins in SLA.

- PostProcessing

The steps taken after printing to enhance the properties and usability of 3D printed parts.

Reference links

Supplementary resources to enhance your learning experience.