Cement – Chemical Composition, Hydration, and Physical Tests

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Chemical Composition of Cement

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's begin our discussion on the chemical composition of cement. The primary components of Ordinary Portland Cement are known as Bogue's Compounds. These include tricalcium silicate, dicalcium silicate, tricalcium aluminate, and tetracalcium aluminoferrite. Can anyone tell me what role tricalcium silicate plays in cement?

I think it’s responsible for providing early strength, right?

That's correct! C₃S is responsible for rapid strength development in the first few days. It reacts quickly with water. What about dicalcium silicate?

It contributes to strength over a longer period.

Exactly! C₂S reacts more slowly, which aids in long-term strength. Now, what about C₃A? It generates a lot of heat, but why is that a concern?

It can lead to problems with sulfate attack if not controlled.

Right! So, it must be regulated in sulfate-resistant cements. Lastly, who can tell me about C₄AF?

It helps with the color of cement and has a minor role in strength development.

Well stated! Remember the acronym C₃S, C₂S, C₃A, C₄AF as the key four components of cement and their roles. To summarize, we learned that each compound has a unique contribution to strength and performance.

Hydration of Cement

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s move on to the hydration of cement. What happens when cement comes in contact with water?

It starts to dissolve immediately, right?

Correct! This is called initial hydrolysis. And what follows?

There’s an induction period where the reaction slows down.

Exactly right! It’s crucial for mixing and placing concrete. After that, we move into the acceleration period. What happens during that phase?

The C₃S and C₂S react more to form calcium silicate hydrate.

Well done! C–S–H is the main binder that provides strength in concrete. Can anyone share what deceleration means in this context?

It’s when hydration continues but at a slower rate.

Exactly! It’s important to remember that hydration is an exothermic process. We need to monitor the heat generated in mass concreting to prevent issues such as thermal cracking. Great job, everyone! Remember the stages: Hydrolysis, Induction, Acceleration, and Deceleration.

Physical Tests on Cement

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

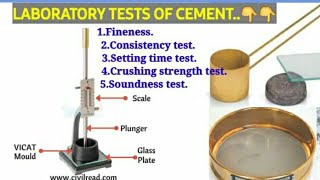

To ensure that cement is suitable for construction, we perform various physical tests according to the IS: 4031 standards. Can someone name one of these tests?

The fineness test measures the particle size, right?

Yes! Finer cement has a larger surface area for hydration. What can you tell me about the standard consistency test?

It measures how much water is needed to form a paste of standard consistency using the Vicat apparatus.

Perfect! Could you share why this test is important?

It's crucial for determining water requirements for setting time and soundness tests.

Exactly! Now, what is the purpose of the setting time test?

It determines how long it takes for the cement to set after mixing with water.

Correct! The initial time should be no less than 30 minutes. What about soundness? Why do we test for it?

To ensure that there are no excessive expansions after setting that could lead to cracking.

Great point! Remember: fineness, consistency, setting time, and soundness are key tests we cover. Excellent engagement today!

Deterioration Mechanisms

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let’s talk about deterioration mechanisms in cement. What do we need to be wary of in terms of sulfate attack?

Sulfate attack can cause expansion and cracking due to the reaction with C₃A.

Exactly! That’s why we should use sulfate-resistant cement in such environments. And what about the alkali-aggregate reaction?

AAR occurs when alkalis in cement react with reactive silica in aggregates, causing cracking.

Correct! It’s a significant concern in concrete structures. Can anyone explain how carbonation affects cement?

Carbonation lowers pH and can lead to the corrosion of steel reinforcements.

Spot on! To minimize these risks, we need to ensure well-cured, dense concrete. Today, we learned critical aspects of both the challenges and tests concerning cement. Great observations!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Cement is crucial in construction as a binding material, with its performance influenced by its chemical makeup and hydration. Key compounds and their roles are discussed, as well as the stages of hydration and tests to assess cement properties.

Detailed

Detailed Summary

Cement is a fundamental binding agent in the construction industry, primarily providing strength and stability to concrete structures. The performance characteristics of cement—such as workability and durability—are heavily influenced by its chemical composition and the hydration process. This section provides insights into:

4.1 Chemical Composition of Cement

Ordinary Portland Cement (OPC) consists of major compounds like tricalcium silicate (C₃S), dicalcium silicate (C₂S), tricalcium aluminate (C₃A), and tetracalcium aluminoferrite (C₄AF). These compounds contribute differently to the properties of cement, from early strength development to long-term durability.

4.1.1 Major Compounds (Bogue’s Compounds)

- C₃S (Tricalcium Silicate): Quick heat release; essential for early strength.

- C₂S (Dicalcium Silicate): Contributes to long-term strength.

- C₃A (Tricalcium Aluminate): Causes initial setting; must be limited for sulfate resistance.

- C₄AF (Tetracalcium Aluminoferrite): Minor in strength contribution; affects color.

4.1.2 Minor Constituents

Impurities like MgO and SO₃ can adversely impact cement properties if not controlled.

4.2 Hydration of Cement

Hydration transforms cement into a solid mass through a series of defined stages:

1. Initial Hydrolysis - Cement dissolves on contact with water.

2. Induction Period - Reaction slows, allowing for workability.

3. Acceleration Period - Formation of C–S–H and calcium hydroxide leads to heat release.

4. Deceleration Period - Continued hydration contributes to long-term strength.

Hydration Products

Key products include Calcium Silicate Hydrate (C–S–H), which provides strength, while calcium hydroxide enhances pH levels in concrete.

Heat of Hydration

Exothermic reactions require monitoring to prevent thermal cracking.

4.3 Physical Tests on Cement

Tests prescribed by IS: 4031 determine suitable properties of cement:

- Fineness Test - Affects hydration rate.

- Standard Consistency Test - Essential for determining water demand.

- Setting Time Test - Measures how quickly cement sets after mixing.

- Soundness Test - Ensures stability post-setting.

- Compressive Strength Test - Fundamental strength evaluation.

- Specific Gravity Test - Indicates density.

- Heat of Hydration Test - Important for mass concrete constructions.

Conclusion

Understanding the chemical and physical properties—and the hydration process of cement—is crucial for engineers to ensure the durability and performance of concrete structures.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to Cement

Chapter 1 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Cement is the most essential binding material used in the construction industry. It acts as a glue in concrete, binding aggregates together and giving strength to the structure. The performance of cement depends significantly on its chemical composition and the physical characteristics it acquires through hydration. Understanding these factors is crucial for engineers, as they directly influence workability, durability, setting time, and long-term strength of concrete structures.

Detailed Explanation

Cement is a key material in construction, functioning as a binder that holds together other components, such as sand and gravel, to form concrete. Its effectiveness and reliability are influenced by its chemical makeup and how it reacts with water during the process of hydration, where it hardens and gains strength. For engineers, it is vital to understand these properties to ensure that concrete performs well over time, as factors like durability and the rate at which it sets are essential for building safe structures.

Examples & Analogies

Think of cement like the glue used in arts and crafts; just as the right glue can make a craft project sturdy and last for years, the correct type of cement ensures that a building remains strong and safe throughout its life.

Chemical Composition of Cement

Chapter 2 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Ordinary Portland Cement (OPC), the most commonly used type of cement, is primarily composed of the following major compounds, which are produced during the manufacturing process:

- C₃S (Tricalcium silicate): 45–60%

- C₂S (Dicalcium silicate): 15–30%

- C₃A (Tricalcium aluminate): 6–12%

- C₄AF (Tetracalcium aluminoferrite): 6–10%

Detailed Explanation

Ordinary Portland Cement (OPC) is a widely used cement type characterized by its specific chemical components, referred to as Bogue's Compounds. These compounds include tricalcium silicate (C₃S), dicalcium silicate (C₂S), tricalcium aluminate (C₃A), and tetracalcium aluminoferrite (C₄AF), each contributing differently to the cement's properties. For instance, C₃S is crucial for providing early strength to the concrete, while C₂S is key for its long-term strength.

Examples & Analogies

Imagine baking a cake where each ingredient affects the flavor and texture. Just like how flour, sugar, and eggs each play a role in making a delicious cake, the various chemical compounds in cement contribute to its performance characteristics, influencing how strong or durable the resulting concrete will be.

Major Compounds in Cement (Bogue’s Compounds)

Chapter 3 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- C₃S – Tricalcium Silicate: Responsible for early strength (1 to 7 days). Reacts quickly with water, releasing a significant amount of heat (exothermic). Contributes to the initial setting and early hardening.

- C₂S – Dicalcium Silicate: Contributes to strength beyond 7 days. Reacts slowly with water, releasing less heat. Important for long-term strength and durability.

- C₃A – Tricalcium Aluminate: Reacts quickly with water and is responsible for the initial setting. Generates a lot of heat. Prone to sulfate attack; hence, regulated in sulfate-resistant cements.

- C₄AF – Tetracalcium Aluminoferrite: Influences the color of cement (gives greyish hue). Has a minor role in strength development. Low heat of hydration.

Detailed Explanation

Each of the major compounds in cement serves distinct functions. Tricalcium silicate (C₃S) is important for early strength, while dicalcium silicate (C₂S) ensures the concrete's long-term strength. Tricalcium aluminate (C₃A) aids in quick setting but can lead to issues such as sulfate attack, requiring careful management in certain environments. Tetracalcium aluminoferrite (C₄AF), although not significantly affecting strength, impacts cement's color and hydration properties.

Examples & Analogies

Consider a car engine where each part has a specific job. Tricalcium silicate (C₃S) is like the fuel that gets the car moving quickly (early strength), while dicalcium silicate (C₂S) is akin to the oil that keeps everything running smoothly over time (long-term durability). The engine components need to work well together to ensure the car drives well, just as these compounds must balance for effective cement performance.

Hydration of Cement

Chapter 4 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Hydration is the chemical reaction between cement and water that results in the formation of a hardened mass. It is an exothermic process and is the key to strength development.

Detailed Explanation

Hydration describes the process by which cement interacts with water. When water is added to cement, a chemical reaction occurs that produces heat and transforms the wet mixture into a solid mass. This is crucial for developing the strength of the concrete. Essentially, without hydration, cement would remain a powder and be ineffective as a construction material.

Examples & Analogies

Think of hydration like the way a sponge absorbs water. When the sponge is dry, it's not very useful, but once it soaks up water, it becomes pliable and strong, ready to do its job. Similarly, when cement hydrates, it changes from a powder to a solid, functioning material that can bear loads.

Stages of Hydration

Chapter 5 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Initial Hydrolysis: Upon contact with water, cement compounds begin to dissolve. C₃A reacts rapidly unless gypsum is added to control flash setting.

- Induction or Dormant Period: Reaction slows down. Concrete remains plastic and workable for about 2–4 hours. Ideal time for mixing, transporting, and placing.

- Acceleration Period: C₃S and C₂S react to form calcium silicate hydrate (C–S–H) and calcium hydroxide (Ca(OH)₂). Initial set occurs; heat evolution increases.

- Deceleration and Steady-State Period: Hydration continues at a slower pace. Strength development continues for months, primarily due to C₂S.

Detailed Explanation

Hydration occurs in several stages. The initial hydrolysis begins as soon as water is added, leading to a rapid reaction especially with C₃A. Then there’s a dormant period where the concrete remains workable, which is beneficial for construction. Following this, an acceleration period occurs where the main strength-forming reactions take place, generating heat. Eventually, the hydration process slows down, but strength continues to develop over time from the remaining reactions, especially with C₂S.

Examples & Analogies

Imagine cooking a multi-step recipe. First, you prepare your ingredients (initial hydrolysis), then let the mixture rest (induction period), before cooking it on the stove (acceleration) until it perfectly simmers down (deceleration). Each step is important to achieve the final delicious dish, just like each stage of hydration is crucial for strong concrete.

Hydration Products

Chapter 6 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Calcium Silicate Hydrate (C–S–H): Main product of hydration. Provides most of the strength. Amorphous in nature, forms a dense gel.

- Calcium Hydroxide (Ca(OH)₂): Also known as lime. Does not contribute to strength. Makes the concrete alkaline (pH ~12.5), which helps prevent corrosion of steel.

- Ettringite: Formed from the reaction between C₃A and gypsum. Controls the setting time. Excess ettringite later can lead to expansion (delayed ettringite formation).

Detailed Explanation

The hydration process produces several key items. Calcium Silicate Hydrate (C–S–H) is the major contributor to the strength of concrete, acting like a binding glue. Calcium Hydroxide (Ca(OH)₂), while not directly contributing to strength, plays an important role in keeping the internal environment alkaline, which is crucial for preventing corrosion in reinforced concrete. Ettringite is formed during the reaction with C₃A and gypsum and is important for controlling the setting time, but excessive amounts can cause issues down the line.

Examples & Analogies

Consider a garden where different plants (hydration products) each play a role in the ecosystem. C–S–H is like a strong tree providing shade (strength), while Ca(OH)₂ is similar to mulch that protects the plants from harmful bugs (corrosion). Ettringite is like a gardener who helps manage the plants’ growth to ensure they thrive but too much can lead to overcrowding.

Physical Tests on Cement

Chapter 7 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

To ensure the suitability of cement for construction, several physical tests are conducted as per IS: 4031 standards. These tests evaluate properties like fineness, setting time, soundness, strength, and consistency.

Detailed Explanation

Physical tests are integral to assessing the quality of cement before it’s used in construction. According to standards, tests evaluate various properties that ensure cement will perform as expected under different conditions. This includes checking how fine the cement is, how long it takes to set, ensuring it doesn’t expand excessively, measuring its strength over time, and verifying its consistency.

Examples & Analogies

Just as a chef would taste and adjust a dish while cooking, engineers must conduct these tests to ensure the cement meets the required standards. If the cement is not right, it can lead to structural failures, similar to how a poorly seasoned dish might ruin a meal.

Key Concepts

-

Chemical Composition: Cement is composed of various compounds that affect its properties.

-

Hydration Stages: Understand the stages of hydration to optimize concrete performance.

-

Physical Testing: Physical tests determine essential properties of cement before use.

-

Deterioration Mechanisms: Factors like sulfate attack and carbonation can degrade cement over time.

Examples & Applications

Example of Cement Compound: C₃S contributes to 70% of the initial strength within the first week.

Example of Hydration Process: During hydration, the formation of C–S–H leads to strength as hydration continues over time.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Cement's four parts are quite the mix, C₃S for strength, then C₂S for fix.

Stories

Imagine a factory where cement is made. With C₃S, it’s strong, and as it hydrates, it bonds with water to create a solid.

Memory Tools

Remember 'C-3P0' as C₃S, C₂S, C₃A, C₄AF; the four companions of cement strength!

Acronyms

HICS

Hydrolysis

Induction

Acceleration

Deceleration - key stages in cement hydration.

Flash Cards

Glossary

- C₃S (Tricalcium Silicate)

Compound in cement responsible for early strength development.

- C₂S (Dicalcium Silicate)

Compound contributing to long-term strength in cement.

- C₃A (Tricalcium Aluminate)

Compound responsible for initial setting in cement but prone to sulfate attack.

- Hydration

The chemical reaction between cement and water that results in a hardened mass.

- Calcium Silicate Hydrate (C–S–H)

Main product of hydration that contributes to strength in concrete.

- Soundness Test

Test to ensure the volume stability of cement after setting.

Reference links

Supplementary resources to enhance your learning experience.