Classification of Plastics

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Plastics

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today we'll discuss the classification of plastics, which is crucial for understanding their properties and uses. Can anyone explain what differentiates thermoplastics from thermosetting plastics?

I think thermoplastics can be reshaped, while thermosetting plastics can't.

That's correct, Student_1! Thermoplastics soften on heating and can be reshaped multiple times, while thermosets undergo a permanent change when heated. A good way to remember is: 'Thermo = reshape, Setting = permanent.'

What are some examples of each type?

Great question! Examples of thermoplastics include PE, PP, and PVC, which are used in applications like packaging and pipes. Thermosetting plastics include Bakelite and epoxy resins, often used in electrical fittings. Remember: PE and PP are 'twice pure', meaning they can be reshaped twice.

Applications of Thermoplastics

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's dive into thermoplastics. What makes them suitable for applications in civil engineering?

I heard they're lightweight and easy to fabricate!

Exactly, Student_3! Their lightweight nature and easy fabrication make them ideal for water tanks, piping, and even insulation. Can anyone think of other advantages?

They're also resistant to corrosion, right?

Correct! Corrosion resistance is vital, especially in environments like pipes and tanks. Remember: thermoplastics can withstand harsh chemicals, as in plumbing.

Understanding Thermosetting Plastics

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s now discuss thermosetting plastics. Why do you think they cannot be reshaped once set?

Because they've already gone through a chemical change that locks them into their shape?

Exactly, Student_1! They undergo a curing process that creates a solid structure. What are some applications for thermosetting plastics?

They’re used in electrical components and adhesives, right?

Great! Their rigidity and heat resistance make them perfect for those applications. Remember: 'Setters stay put!'

Comparison of Thermoplastics and Thermosets

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's compare thermoplastics and thermosetting plastics. Can anyone summarize their key differences?

Thermoplastics can be reshaped, while thermosets are permanent. Thermoplastics are more flexible, I think!

Right on, Student_3! Another point is that thermoplastics typically have lower mechanical strength compared to thermosets, which are stronger and more durable.

Is there a memory aid for this?

Absolutely! Think of 'Thermo for melting, Set for strong' to remember their properties.

Applications Recap

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Before we end, let’s recap the applications of both thermoplastics and thermosetting plastics. What did we learn?

Thermoplastics are used for things like packaging and pipes, while thermosets are for electrical fittings and adhesives.

Excellent summarization! Always remember: flexibility vs. permanence in planning applications is key!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The classification of plastics focuses on their thermal behavior, dividing them into thermoplastics, which can be reshaped and reused, and thermosetting plastics, which undergo a permanent chemical change. This classification is fundamental to understanding their properties and applications in various fields, particularly in civil engineering.

Detailed

Classification of Plastics

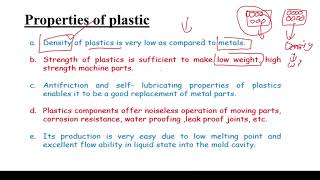

Plastics are widely recognized for their versatility and applicability in various fields, especially in civil engineering. They are primarily classified based on their thermal behavior into two categories:

1.1 Thermoplastics

- Characteristics: Thermoplastics soften on heating and harden upon cooling, making their reshaping reversible. They can be remolded multiple times without significant chemical change.

- Examples: Common types include Polyethylene (PE), Polypropylene (PP), Polyvinyl chloride (PVC), Polystyrene (PS), Polymethyl methacrylate (PMMA), and Nylon.

- Applications: Utilized in water tanks, pipes, packaging, and insulation due to their adaptability and ease of processing.

1.2 Thermosetting Plastics

- Characteristics: Unlike thermoplastics, thermosetting plastics undergo a permanent chemical change when heated. Once set, they cannot be remolded.

- Examples: Notable examples are Phenol-formaldehyde (Bakelite), Urea-formaldehyde, Epoxy resins, and Melamine.

- Applications: Common in electrical fittings, laminates, adhesives, and as a matrix in fiber-reinforced composites.

By understanding the classification of plastics, engineers can make informed choices regarding material selection based on the required properties for construction and structural applications.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Thermoplastics

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Soften on heating and harden on cooling (reversible process).

• Can be reshaped multiple times.

• Examples: Polyethylene (PE), Polypropylene (PP), Polyvinyl chloride (PVC), Polystyrene (PS), Polymethyl methacrylate (PMMA), Nylon.

• Applications: Water tanks, pipes, packaging, insulation.

Detailed Explanation

Thermoplastics are a type of plastic that can be repeatedly softened by heating and hardened by cooling, allowing them to be reshaped multiple times. This is due to the linear structure of their polymer chains, which allows them to be rearranged when heated. Common examples of thermoplastics include materials like Polyethylene (PE), widely used in plastic bags, and Polyvinyl Chloride (PVC), which is typically used in pipes and window frames. They are notably used in applications like water tanks and insulation due to their properties of corrosion resistance and insulation capabilities.

Examples & Analogies

Think of thermoplastics like playdough. When you heat it (or warm it in your hands), it becomes soft and moldable. You can shape it into different forms and, once cooled, it will retain that shape until you heat it again and reshape it. This allows for creativity and flexibility in various applications, much like how thermoplastics are used to produce various everyday items.

Examples of Thermoplastics

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Examples: Polyethylene (PE), Polypropylene (PP), Polyvinyl chloride (PVC), Polystyrene (PS), Polymethyl methacrylate (PMMA), Nylon.

Detailed Explanation

This chunk lists some common examples of thermoplastics and highlights their diversity. Polyethylene (PE) is considered the most widely used plastic due to its adaptability, often found in packaging and containers. Polypropylene (PP) is known for its durability and is commonly used in automotive parts and textiles. Polyvinyl Chloride (PVC) is utilized in both plumbing and electrical applications. Polystyrene (PS) is found in products like disposable cutlery and insulation materials, while Polymethyl Methacrylate (PMMA) is used in clear acrylic sheets as a glass substitute. Lastly, Nylon is well-known for its strength and is prevalent in textiles and mechanical parts.

Examples & Analogies

Consider the variety found in a toolbox. Just as you have different types of tools for specific tasks—like hammers for pounding nails or wrenches for tightening bolts—different thermoplastics serve specific purposes across various industries. For example, while PE may be ideal for lightweight packaging, PVC is better suited for plumbing because of its ability to withstand water pressure.

Thermosetting Plastics

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Undergo permanent chemical change when heated.

• Cannot be remolded after setting.

• Examples: Phenol-formaldehyde (Bakelite), Urea-formaldehyde, Epoxy resins, Melamine.

• Applications: Electrical fittings, laminates, adhesives, matrix in fiber-reinforced composites.

Detailed Explanation

Thermosetting plastics are another category of plastics, which, unlike thermoplastics, undergo a permanent chemical change when they are heated and molded. This means they cannot be reshaped once they have set. Thermosets include materials like Bakelite, which is used in electrical fittings due to its insulation properties, and Epoxy resins, which are widely used in adhesives and fiber-reinforced composites due to their strong bonding capabilities. Their application is vital in areas requiring high strength and durability.

Examples & Analogies

Imagine making a cake. When you mix the batter and then heat it in the oven, it undergoes a chemical change that transforms it into a solid cake. Once baked, you cannot revert it to batter form. Similarly, thermosetting plastics change permanently when heated and cannot be reshaped, making them suitable for applications like manufacturing durable electrical components.

Examples of Thermosetting Plastics

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Examples: Phenol-formaldehyde (Bakelite), Urea-formaldehyde, Epoxy resins, Melamine.

Detailed Explanation

This section lists examples of thermosetting plastics, each highlighting distinct properties beneficial for various applications. Bakelite, the first synthetic plastic, is used highly in electrical components due to its excellent insulating qualities. Urea-formaldehyde is prominent in the production of laminates and adhesives. Epoxy resins are favored for their strong adhesive properties, making them useful in many industrial applications. Melamine is used for its hardness and is primarily found in kitchenware and decorative surfaces.

Examples & Analogies

Think of thermosetting plastics as sturdy, heavy-duty tools compared to lighter, more flexible tools like those made from thermoplastics. For instance, using Bakelite for electrical components is similar to choosing a hammer made of steel rather than plastic for heavy-duty tasks; it’s stronger and more reliable for specific applications where durability is crucial.

Key Concepts

-

Thermoplastics: Can be reshaped multiple times upon heating.

-

Thermosetting Plastics: Undergo permanent changes and cannot be reshaped.

-

Examples of Thermoplastics: Polyethylene, Polypropylene, PVC, Polystyrene.

-

Examples of Thermosetting Plastics: Bakelite, Urea-formaldehyde, Epoxy resins.

-

Applications: Used in construction, electrical fittings, packaging, etc.

Examples & Applications

Polyethylene is commonly used in plastic bags due to its flexibility.

Bakelite is used in electrical insulators because it can withstand heat.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Thermoplastics melt, then shape anew, / But thermosets stay firm, forever true.

Stories

Imagine a pot of warm plastic that easily takes any shape, while a baked clay sculpture stays the same forever. That's the tale of thermoplastics and thermosets.

Memory Tools

Think 'Melt and Mold' for thermoplastics, and 'Solidify and Stay' for thermosets.

Acronyms

Remember the 'TPT' – Thermoplastics are Thermal and Transformable.

Flash Cards

Glossary

- Thermoplastics

Plastics that soften upon heating and can be reshaped; examples include PE, PP, and PVC.

- Thermosetting Plastics

Plastics that undergo a permanent chemical change when heated; examples include Bakelite and epoxy resins.

- Polyethylene (PE)

A common thermoplastic used for packaging and containers.

- Polypropylene (PP)

A versatile thermoplastic commonly used in automotive parts, textiles, and packaging.

- Polyvinyl Chloride (PVC)

A widely-used thermoplastic for making pipes, flooring, and cable insulation.

- Bakelite

A type of thermosetting plastic used primarily for electrical insulators and kitchenware.

Reference links

Supplementary resources to enhance your learning experience.