Creep of Concrete

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Definition and Importance of Creep

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Good morning, everyone! Today, we will dive into the concept of creep in concrete. Can anyone tell me what they think creep is?

I think it's some kind of change in shape or size over time?

Exactly! Creep is the gradual increase in strain in concrete when it's under constant stress over a long duration. Unlike elastic deformation, which returns when the load is removed, creep is time-dependent. It’s crucial for us in engineering because it affects long-term stability of structures.

So, is it only for concrete?

Great question! While we're focusing on concrete, creep can occur in other materials as well. But the mechanisms vary across materials. Let's explore how factors like moisture and stress levels influence creep.

Mechanism and Types of Creep

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's discuss how creep actually happens. Can someone mention a mechanism behind it?

I read something about moisture or fluid movement? Does that relate?

Yes! Moisture movement in the gel pores contributes to creep along with viscous flow in the cement paste and microcracking in transition zones. These processes are critical, especially in the different types of creep we've identified: basic creep, drying creep, and autogenous creep.

What’s the difference between drying creep and autogenous creep?

Drying creep occurs when concrete loses moisture under load, which can enhance creep significantly. Autogenous creep, on the other hand, happens even without external moisture and is significant in high-strength concrete. Consider it as 'internal shrinkage.'

Factors Affecting Creep

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s move on to what influences creep. Can anyone name one factor affecting creep?

Is it the amount of water in the concrete mix?

Correct! The water-cement ratio plays a significant role; higher ratios increase creep due to greater porosity. Other factors include stress level, age at loading, and moisture conditions. For instance, loads applied early often lead to more creep.

And temperature matters too, right?

Absolutely! Higher temperatures can accelerate the creep rate. Good observation! Remember these factors as they are key during the design phase of structures.

Measurement of Creep

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let's talk about how we measure creep. Do any of you have ideas on what tools or methods might be used?

Maybe using sensors that measure strain over time?

Exactly! A creep test typically uses a creep frame with a defined load and gauges like dial gauges or LVDTs to measure strain. We can also use a creep coefficient to quantify the relationship of creep strain to elastic strain.

So our measurements can guide us in making better designs?

Yes, that's the goal! Understanding these measurements ensures we design structures that can withstand expected loads over their lifetimes.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The creep phenomenon describes how concrete experiences gradual deformation when subjected to constant stress over time, which is crucial for civil engineers to consider in structural design. Various factors influence the degree of creep, including the applied stress level, moisture conditions, and type of cement used.

Detailed

Creep of Concrete

Concrete is a widely used construction material known for its strength and durability; however, it experiences time-dependent deformations known as creep and shrinkage. Creep refers specifically to the gradual increase in strain under sustained load, unlike elastic deformation which is immediate and reverse upon load removal. This section delves into the mechanisms of creep, its types, factors influencing it, and methods of measurement, emphasizing its significance in the design of high-rise structures and critical infrastructures.

1.1 Definition

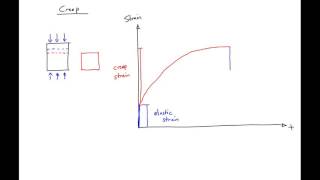

Creep is defined as the gradual increase in strain due to a constant applied stress over an extended period.

1.2 Mechanism of Creep

The mechanism of creep arises mainly from the viscoelastic nature of the cement paste which includes:

- Moisture movement within gel pores

- Viscous flow of hydrated cement paste

- Microcracking in transition zones

- Structural rearrangements in calcium silicate hydrate (C-S-H) gel.

1.3 Types of Creep

- Basic Creep: Occurs under constant load in a sealed environment.

- Drying Creep: Enhances creep when moisture is lost under load.

- Autogenous Creep: Exists in high-strength concrete without external moisture movement, primarily due to internal chemical shrinkage.

1.4 Factors Affecting Creep

Factors influencing creep include:

- Applied stress level

- Water-cement ratio

- Age at loading

- Moisture conditions

- Aggregate content

- Type of cement

- Temperature

1.5 Measurement of Creep

Creep tests involve using specific setups to measure the deformative response of concrete under controlled conditions. The creep coefficient θ is used to quantify thereacting relationship of creep strain to elastic strain and is critical in assessing material behavior in civil engineering design applications.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Definition of Creep

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

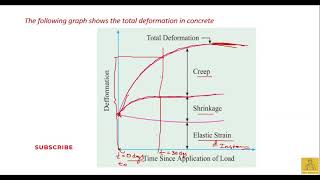

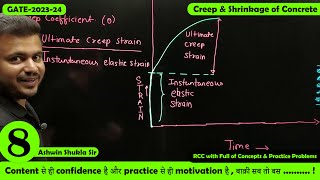

Creep is the gradual increase in strain or deformation in concrete when it is subjected to a constant stress over a long period. Unlike elastic deformation, creep is time-dependent and continues as long as the stress is applied, even if the load remains unchanged.

Mathematically:

Total Strain=Elastic Strain+Creep Strain

Detailed Explanation

Creep in concrete refers to the slow and continuous deformation that occurs when the material is under a constant load over time. This behavior differs from elastic deformation, which is the immediate response to a load and can be reversed once the load is removed. Creep takes time to develop and continues as long as the load is applied. For understanding this mathematically, the total strain of concrete is composed of two parts: its elastic strain (the immediate response) and creep strain (the slow deformation over time).

Examples & Analogies

Imagine a sponge that, when pressed down, flattens a bit under a heavy weight. If you press down on it for a long time, you'll notice that it doesn’t bounce back entirely after you remove the weight. The change in shape it undergoes while the weight is on it represents creep.

Mechanism of Creep

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Creep primarily occurs due to the viscoelastic nature of the cement paste. The mechanism includes:

- Moisture movement in the gel pores

- Viscous flow of the hydrated cement paste

- Microcracking within the transition zones

- Internal structural rearrangements in the calcium silicate hydrate (C-S-H) gel

Detailed Explanation

Creep happens because concrete has a viscoelastic nature, meaning it behaves both like a solid and a fluid over time. The process involves several mechanisms:

1. Moisture movement within the tiny pores of the concrete can lead to changes in shape and volume.

2. The viscous flow of the cement paste, which is somewhat fluid-like, allows parts of the material to rearrange slowly.

3. Microcracking occurs when small cracks develop within the transition zones, where different materials meet.

4. Finally, internal restructuring happens within the C-S-H gel, which is the main binding phase in concrete that can slowly change over time due to stress.

Examples & Analogies

Think of a loaf of bread. When it's first baked, it has a firm structure. If you apply pressure to it, the bread starts to compress and change shape slowly, especially if it has some moisture inside. This process is akin to how concrete deforms under sustained load through the movement of moisture and microstructural changes.

Types of Creep

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Basic Creep: Occurs when concrete is loaded in a sealed environment without moisture exchange.

- Drying Creep (Pickett Effect): Occurs when concrete loses moisture under load. Drying enhances creep significantly.

- Autogenous Creep: Happens even in the absence of external moisture movement, especially significant in high-strength concrete due to internal chemical shrinkage.

Detailed Explanation

Creep can be categorized into three main types:

1. Basic Creep happens under conditions where there is no moisture exchange, allowing creep to proceed unimpeded.

2. Drying Creep, also known as the Pickett Effect, describes the increased deformation that occurs when concrete dries out while under load. Loss of moisture increases the magnitude of creep.

3. Autogenous Creep refers to creep in concrete that can happen even when no moisture is lost externally, particularly in high-strength concrete, where internal reactions occur that cause it to shrink.

Examples & Analogies

Think of how a sponge may deform if you leave it in a sealed container versus when it's drying out on a surface. In the sealed container (Basic Creep), it slowly loses its firmness. On the other hand, if you leave a wet sponge in the sun (Drying Creep), it shrinks and deforms more quickly. Autogenous Creep is like a sponge that, while still wet, starts to shrink inside from the chemical reactions occurring as it dries.

Factors Affecting Creep

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Stress Level: Creep is approximately proportional to the applied stress (below 30-40% of compressive strength).

- Water-Cement Ratio (w/c): Higher w/c increases creep due to higher porosity.

- Age at Loading: Concrete loaded at an early age shows more creep.

- Moisture Conditions: High ambient humidity reduces creep; drying conditions accelerate it.

- Aggregate Content: Richer mixes with less aggregate show more creep.

- Type of Cement: Slow-hydrating cements (e.g., Type IV) show less creep.

- Temperature: Higher temperatures accelerate creep rate.

Detailed Explanation

Several factors influence the amount of creep in concrete:

- Stress Level: Higher loads lead to more significant creep, especially if they are below 30-40% of concrete's strength.

- Water-Cement Ratio: A higher ratio means more water, creating a more porous structure, which increases susceptibility to creep.

- Age at Loading: Loading concrete at a younger age tends to result in increased creep compared to loading it when it's fully cured.

- Moisture Conditions: Excess moisture in the air can reduce creep, while dried-out conditions can accelerate it.

- Aggregate Content: Concrete mixtures with less aggregate (more paste) are prone to more creep because there is not as much material to restrain the deformation.

- Type of Cement: Different cements hydrate at different rates; slower cements lead to less creep.

- Temperature: Warmer conditions accelerate the chemical processes contributing to creep.

Examples & Analogies

Consider how a piece of dough rises in a warm environment (higher temperature conditions), stretching and changing shape faster than it would in a colder condition. Similarly, in concrete, a warmer environment or more water can lead to quicker and more pronounced creep behavior.

Measurement of Creep

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

A creep test is conducted using:

- A creep frame with dead load.

- Dial gauges or LVDTs to record strain.

- Companion specimens without load to isolate shrinkage from total deformation.

The Creep Coefficient is a commonly used parameter:

Creep Strain

ϕ=

Elastic Strain at loading

Typical values:

- Normal concrete: φ = 1.5 to 2.5

- High-strength concrete: φ = 0.8 to 1.5

Detailed Explanation

To measure creep, engineers perform specific tests known as creep tests. These involve using a creep frame that applies a constant load to concrete specimens. Tools like dial gauges or Linear Variable Differential Transformers (LVDTs) measure how much the material deforms (strain) over time under this load. They often compare loaded specimens to unloaded specimens to distinguish between creep and shrinkage. The Creep Coefficient is an important value that expresses the ratio of creep strain to the elastic strain at the moment of loading, helping in analyzing how much deformation will occur. Typical values indicate that normal concrete has a creep coefficient ranging from 1.5 to 2.5, whereas high-strength concrete typically sees lower values around 0.8 to 1.5.

Examples & Analogies

Think of measuring how much a spring stretches under a weight over time. If you put a weight on a spring and keep track of how far it extends, this could relate to measuring creep in concrete. The comparison of resting versus loaded springs helps us understand what deformation is purely due to the load versus the natural stretching.

Key Concepts

-

Total Strain: The overall deformation of concrete under load, including both elastic and creep strains.

-

Viscoelastic Nature: The property of concrete to exhibit both viscous and elastic behavior under stress and strain.

-

Moisture Movement: The process affecting creep, where moisture displacement in concrete influences deformation.

-

Creep Measurement: Techniques involving special equipment to assess the creep strain in concrete.

Examples & Applications

A bridge designed without acknowledging creep led to significant misalignment of structure components over time, necessitating costly retrofits.

High-rise buildings may experience continuous deflection at mid-spans due to unaccounted creep, affecting overall structural integrity.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Creep is slow, it flows with time, under load it bends, like a mountain's climb.

Stories

Once upon a time, there was a tall tree under heavy rain. Even though it stood strong, the constant moisture made it slowly bend over years, representing concrete’s creep under pressure and moisture.

Memory Tools

Use the acronym SWAT to remember Factors affecting creep: Stress, Water-cement ratio, Age at loading, Temperature.

Acronyms

CREAT - Creep is Related to

Elastic strain

Age

Temperature.

Flash Cards

Glossary

- Creep

The gradual increase in strain in concrete subjected to a constant stress over a long period.

- Basic Creep

Creep occurring when concrete is under load in a sealed environment.

- Drying Creep

Creep that occurs when concrete loses moisture while under load.

- Autogenous Creep

Creep that happens in high-strength concrete due to internal chemical shrinkage without moisture loss.

- Creep Coefficient

The ratio of creep strain to elastic strain at loading.

Reference links

Supplementary resources to enhance your learning experience.