PID Control Strategy

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to PID Control

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're diving into PID Control. PID stands for Proportional, Integral, and Derivative. It's a control loop feedback mechanism that's widely used in industrial control systems.

Why is it so popular in engineering applications?

Great question! Its popularity comes from its simplicity and effectiveness. It helps to reduce errors in various applications.

Can you explain what each part does?

Sure! The proportional part reacts to the current error, the integral part considers past errors to eliminate steady-state errors, and the derivative part predicts future errors based on their rate of change.

Can you give an example?

Absolutely! For instance, in a furnace, the PID controller adjusts heating power to maintain the desired temperature efficiently.

To remember the roles, think of PID as 'Proactive In Decision-making' where it adjusts based on present, past, and expected future scenarios.

To summarize, PID is a feedback control system that combines three actions to enhance system performance. The key takeaway is its versatility in applications.

Applications of PID Control

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now that we understand what PID is, let’s talk about its applications. Where do you think PID Control is used?

Maybe in air conditioning systems?

Exactly! PID controllers are employed in HVAC systems to maintain temperature by adjusting fan speeds and heating levels.

What about motors? I think they use PID too.

Yes! In DC motors, PID controls the speed by adjusting the voltage based on how much the current speed deviates from the target speed.

And in robotics?

Exactly! Robotics often utilizes PID control to maintain precise positions and orientations. Great connections!

To sum up, PID Control applications include temperature management, motor speed control, and robotics, showcasing its broad utility.

Resolving Control Issues with PID

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let's explore how PID helps to resolve control issues like overshoot and steady-state errors. Who can explain what 'overshoot' means?

It's when a system exceeds its target value temporarily before settling down, right?

Exactly! The derivative part helps to mitigate this by reacting to the rate of change of the error.

What about the steady-state error?

The integral action addresses steady-state errors by accumulating past errors over time, ensuring that the output converges to the setpoint.

So, if a furnace misses the target temperature, the integral part will correct it by looking back at how it deviated in the past?

That's correct! PID helps ensure stability and reduces oscillation, which is essential in control systems.

In summary, PID effectively manages overshoot and steady-state errors, thus improving overall system stability.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The PID Control Strategy is central to engineering applications, employing three actions: proportional control to address current errors, integral control to eliminate steady-state errors by accumulating past errors, and derivative control to predict future errors based on their rate of change. This method is versatile, applied in various fields including temperature control, motor speed regulation, and robotics.

Detailed

PID Control Strategy

PID (Proportional-Integral-Derivative) Control is the most widely used control strategy in engineering. It functions by combining three control actions:

- Proportional: Addresses the current error present in the system. The larger the error, the larger the control output.

- Integral: Eliminates the steady-state error by summing up past errors over time, allowing the control strategy to adjust and correct for any accumulated differences.

- Derivative: Anticipates future errors based on the rate of change of the error signal, enabling faster response to changes in the system.

PID Control is used across several applications:

- Temperature Control in systems such as furnaces and air-conditioning to maintain set temperatures.

- Motor Speed Control in DC motors, adjusting voltage according to speed deviation.

- Robotics like maintaining the position and orientation in robotic arms and drones.

For example, in a furnace heating system, a PID controller ensures that the temperature remains at a specified value by adjusting the heating power. This minimizes overshoot and steady-state errors, showcasing the effectiveness of PID control in practical applications.

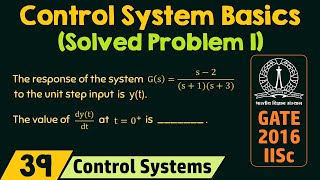

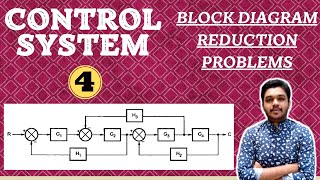

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Overview of PID Control

Chapter 1 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

PID Control is the most widely used control strategy in engineering applications. It uses three basic actions—proportional, integral, and derivative—to adjust the system output:

Detailed Explanation

PID Control, which stands for Proportional-Integral-Derivative Control, is a fundamental controller in engineering that helps manage the output of systems. Its purpose is to achieve a desired performance by adjusting the system output based on three actions: proportional, integral, and derivative. Each component plays a specific role in guiding the output toward the target.

Examples & Analogies

Think of a PID controller like a thermostat in your home. The thermostat continuously measures the room temperature (the current state) and compares it to the desired temperature (the setpoint). If the room is too cold, the proportional action increases heating. If it has been too cold for a while, the integral action helps ensure warmth does not lag, and the derivative action prepares for any temperature changes ahead by adjusting the heating rate.

Proportional Action

Chapter 2 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Proportional: Reacts to the current error.

Detailed Explanation

The proportional action is responsible for reacting based on the present error, which is the difference between the desired setpoint and the current output of the system. If the error is large, the controller generates a large output to correct the current state. Conversely, if the error is small, the output is minor.

Examples & Analogies

Imagine driving a car. If you’re steering significantly off course (a big error), you’ll turn the steering wheel a lot to correct your path (large output). If you’re almost on track (small error), a gentle touch on the wheel will suffice.

Integral Action

Chapter 3 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Integral: Eliminates steady-state error by considering past errors.

Detailed Explanation

The integral action addresses any accumulated errors over time. If the system consistently remains off the desired setpoint, the integral term increases the controller output to eliminate this persistent error known as steady-state error, ensuring that the system ultimately stabilizes at the desired value.

Examples & Analogies

Consider a student who consistently scores below their target on exams. The integral action is like realizing that their study habits need adjustment based on all past performances. They might decide to study more hours to gradually achieve their score goal, eliminating their steady underperformance.

Derivative Action

Chapter 4 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Derivative: Predicts future error based on the rate of change.

Detailed Explanation

The derivative action helps to anticipate future errors by measuring the rate at which the current error is changing. If the error is increasing rapidly, the controller can react more aggressively to prevent overshooting the setpoint by adjusting the output promptly.

Examples & Analogies

This action is akin to a driver using a rearview mirror to observe how quickly they are approaching the stop sign. If they see they are approaching too quickly, they will begin to slow down sooner rather than later, preventing a sudden stop that could cause discomfort or danger.

Applications of PID Control

Chapter 5 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Applications:

1. Temperature Control: PID controllers are used in systems such as furnaces, ovens, and air-conditioning systems to maintain a set temperature.

2. Motor Speed Control: In DC motors, PID controllers regulate the speed by adjusting the voltage applied to the motor based on speed deviations.

3. Robotics: PID control is widely used to maintain position and orientation in robotic arms and drones.

Detailed Explanation

PID control is versatile and utilized in various applications across different fields. In temperature control systems like furnaces and air conditioners, PID helps maintain a consistent temperature. In motor systems, it ensures that the speed of the motor remains steady, and in robotics, it helps control movements, positions, and orientations accurately.

Examples & Analogies

Think of a PID controller in an air-conditioning system like a chef cooking a dish. The chef continuously tastes the food (the process) and adjusts the seasonings (outputs) based on the taste (feedback) until the dish reaches perfection (the setpoint). For a motor, it’s similar to a bicycle rider adjusting their pedaling speed based on how fast they want to go when riding uphill or downhill.

Example Problem: Temperature Control in a Furnace

Chapter 6 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

In a furnace heating system, the temperature needs to be maintained at a set value. A PID controller can adjust the heating power to ensure that the temperature follows the desired trajectory, minimizing both steady-state error and overshoot.

Detailed Explanation

In this example, the PID controller regulates a furnace's temperature. If the temperature falls below the set value, the proportional component adjusts the heating power. If this low temperature has been an issue for a while, the integral component boosts the heating further to address the ongoing error. Lastly, the derivative component helps control heating intensity to avoid overshooting the desired temperature.

Examples & Analogies

Picture the furnace like a kettle on the stove. When you want hot water, you turn the burner on (proportional), but if you often run the kettle too cool, you might let it boil longer to ensure it’s always hot enough (integral). You also keep an eye on it to avoid letting it boil over (derivative), adjusting the flame as needed based on how it heats up.

Key Concepts

-

PID Control: A feedback control strategy using Proportional, Integral, and Derivative actions.

-

Proportional Action: Reacts to the current error.

-

Integral Action: Eliminates steady-state error by considering past errors.

-

Derivative Action: Predicts future error based on the rate of change.

Examples & Applications

Temperature control in furnaces using PID to maintain the desired temperature.

Motor speed control in DC motors adjusting voltage based on current speed deviations.

Position control in robotic arms ensuring precise orientation using PID.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

For PID control, three things we see, Proportional, Integral, Derivative—so key!

Stories

Imagine a car trying to stay at a constant speed. The driver reacts to the current speed (proportional), adjusts for past speeds if it has been too slow in a while (integral), and predicts future speeds based on how fast it's changing right now (derivative) to avoid problems. That’s PID in action!

Memory Tools

P for Present (Proportional), I for In the past (Integral), D for Dreaming of the future (Derivative).

Acronyms

PID = Present + In the past + Dreaming (to anticipate).

Flash Cards

Glossary

- Proportional Control

A control action that reacts to the current error in the system.

- Integral Control

A control action that sums past errors to eliminate steady-state errors.

- Derivative Control

A control action that predicts future errors based on the rate of change of the error.

- SteadyState Error

The persistent error that occurs when a system reaches a steady operating condition.

- Overshoot

When a system exceeds its target value temporarily before stabilizing.

- PID Controller

A control loop feedback mechanism that uses proportional, integral, and derivative actions.

Reference links

Supplementary resources to enhance your learning experience.