Ductile vs. Brittle Failure

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Ductile and Brittle Failure

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we are going to explore two critical types of material failure: ductile and brittle failure. Can anyone give me a basic definition of ductile failure?

I think ductile failure is when a material bends or deforms a lot before it breaks.

Exactly! Ductile failure allows for significant plastic deformation before catastrophic failure. Now, who can explain what brittle failure is?

Brittle failure is when a material breaks suddenly without much deformation.

Correct! Ductile failure is more gradual, while brittle failure happens suddenly. Let's remember this with the acronym 'DB' — Ductile Bends, Brittle Breaks. Now, what are the implications of these failures in engineering?

If something fails ductily, we might have time to fix it, but with brittle failure, there’s no warning!

That’s a very important point! Let's move on to specific examples.

Energy Absorption and Failure Modes

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's talk about energy absorption. Why is this important in the context of earthquakes?

Because if a building can absorb energy, it can survive intense shaking!

Exactly right! Ductile structures can absorb and dissipate energy, minimizing immediate damage. Can anyone tell me how the failure mode differs between ductile and brittle failures?

Ductile failure is more gradual, which means we can see when things are getting worse before it collapses. Brittle failure happens very quickly without much notice.

That’s the spirit! Brittle failures tend to be catastrophic and can cause severe consequences. If you can associate energy absorption with the term 'Caution,' you'll remember it better!

Implications of Failure Types in Design

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now that we understand ductility and brittleness, how can these concepts guide structural design in earthquakes?

We should design buildings to fail ductilely to give warnings and time for evacuation.

Great observation! Modern codes focus on ductility to ensure that the structures can endure seismic activity. Why do you think this is critical from a safety standpoint?

It’s because a ductile structure can save lives by providing warning signs before total collapse.

Exactly, student_3! High ductility reduces the chances of catastrophic failures during seismic events. Remember that with our phrase: 'Ductile for Safety!'

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Ductile failure involves significant plastic deformation before failure, providing advanced warning and absorbing energy, while brittle failure occurs suddenly with little to no deformation. Ductile failure is preferred in seismic design to prevent catastrophic collapse, enhancing the safety of structures.

Detailed

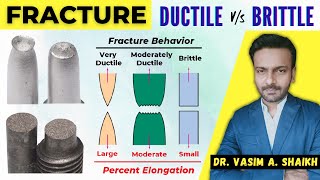

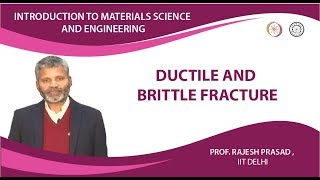

Ductile vs. Brittle Failure

Ductile and brittle failures represent two critical modes of failure in materials and structures. Understanding their characteristics is essential for effective earthquake-resistant design.

Characteristics of Ductile Failure

- Deformation: Large plastic deformation prior to failure.

- Warning before Failure: Provides noticeable warning, allowing for preventive actions.

- Energy Absorption: High capacity to absorb energy, typically leading to a gradual failure rather than an immediate collapse.

- Failure Mode: Generally gradual, allowing for redistribution of forces within the structure.

Characteristics of Brittle Failure

- Deformation: Exhibits little or no plastic deformation before failure.

- Warning before Failure: Occurs without warning, often catching engineers and occupants unprepared.

- Energy Absorption: Low energy absorption capacity, leading to sudden failure.

- Failure Mode: Sudden and catastrophic, often resulting in extensive damage to the structure.

In the context of earthquake engineering, ductile failure is preferred since it offers potential control over structural failure, enhancing building survivability and safety. Brittle failures, such as shear failures in concrete, have the potential for severe consequences in earthquake scenarios. For these reasons, modern seismic design standards advocate for ductile designs, which allow structures to endure and respond adaptively to extreme dynamic loads.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Definition of Ductile Failure

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Ductile failure is characterized by large plastic deformations before failure occurs. It is a gradual process, allowing structures to bend and absorb energy throughout deformation.

Detailed Explanation

Ductile failure happens when a material can undergo significant deformation before it actually breaks. Think of it like bending a piece of clay; before it finally breaks apart, it changes shape gradually. This allows for energy absorption and often provides a warning before ultimate failure, giving occupants time to evacuate.

Examples & Analogies

Imagine a steel beam in a building during an earthquake. As the building sways, the beam bends and flexes (deforms) but doesn’t break immediately. Instead, it gives warning signs, such as creaking sounds, before it finally fails, just like bending a rubber band before it snaps.

Definition of Brittle Failure

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Brittle failure is characterized by little or no plastic deformation before failure occurs. This type of failure is sudden and often happens without warning.

Detailed Explanation

Brittle failure occurs when a material breaks suddenly with little to no deformation beforehand. This means that instead of bending or twisting, the material just fractures. We often see this in materials like glass or brittle concrete, where they break cleanly and without any prior warning signs.

Examples & Analogies

Think of a porcelain cup falling to the floor. It doesn’t bend; it shatters immediately upon impact. This is similar to brittle failure in materials that don’t flex or deform, providing no indication that they are about to break.

Comparison of Ductile and Brittle Failure

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

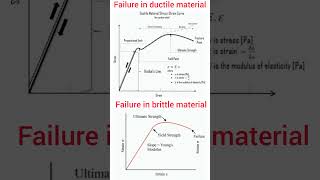

Characteristics

- Deformation: Ductile failure involves large plastic deformation, while brittle failure exhibits little or no plastic deformation.

- Warning Before Failure: Ductile failure gives a warning, whereas brittle failure does not.

- Energy Absorption: Ductile materials absorb high amounts of energy before failure, unlike brittle materials.

- Failure Mode: Ductile failure is gradual, while brittle failure is sudden.

Detailed Explanation

In comparing ductile and brittle failures, we can see clear distinctions. Ductile materials can bend and flex, absorbing energy and allowing for some warning before total failure occurs. Conversely, brittle materials snap without prior warning and absorb little to no energy. Understanding these differences is crucial in engineering, especially for structures intended to withstand seismic events.

Examples & Analogies

Consider a bridge made of steel (ductile) versus one made of concrete (brittle). In an earthquake, the steel bridge might sway and flex, allowing engineers to recruit energy and avoid catastrophe. In contrast, if the concrete bridge experiences similar forces, it could snap without warning, resulting in disaster for anyone using it.

Importance of Ductile Failure in Seismic Design

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Ductile failure is preferred in seismic design since brittle failure (like shear failure in concrete) can be catastrophic and occur without warning.

Detailed Explanation

In seismic design, ductility is crucial because it provides structures the ability to deform and absorb energy during earthquakes. This ability to deform is fundamental to ensure that buildings do not collapse unexpectedly. Engineers favor ductile materials in construction to enhance safety during seismic events.

Examples & Analogies

Think of a dancer on stage who can adapt their movements gracefully to avoid falling over. If a dancer is rigid and cannot adjust, even a small misstep can lead to a fall. Similarly, buildings designed with ductility can absorb shock and sway during an earthquake, while brittle structures are at risk of a sudden and complete failure.

Key Concepts

-

Ductile Failure: Involves significant deformation before it leads to failure, providing a safety buffer.

-

Brittle Failure: Characterized by sudden collapse with minimal deformation, leading to immediate hazards.

-

Energy Absorption: A vital characteristic of ductile materials that facilitates controlled failure and resource management during seismic activities.

Examples & Applications

Steel is a ductile material; it bends significantly before breaking, thus preferable in earthquake-prone areas.

Concrete often exhibits brittle failure, especially when under shear stress, making it a concern in seismic design.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Brittle breaks with no time for a shout; ductile bends, making it about!

Stories

Once there was a strong tree (ductile) that bent during storms, allowing squirrels to escape. The brittle branch, however, snapped without a sound, leaving no time for warning.

Memory Tools

Remember 'DB' for Ductile Bends and Brittle Breaks to distinguish between their failure modes.

Acronyms

Use 'DEW' to recall that Ductile materials give early Warning (D), exhibit Energy absorption (E), and deform (W) before failure.

Flash Cards

Glossary

- Ductile Failure

A type of failure characterized by significant plastic deformation before fracture, providing warnings and allowing energy absorption.

- Brittle Failure

A type of failure that occurs suddenly with little to no plastic deformation, often resulting in catastrophic outcomes.

- Energy Absorption

The capacity of a structure to absorb energy during deformation, crucial in seismic design.

- Failure Mode

The manner in which a material or structure fails, influencing the overall safety and integrity.

Reference links

Supplementary resources to enhance your learning experience.