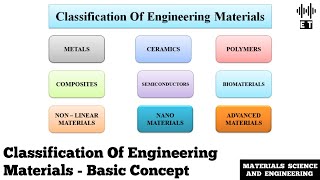

Classification of Engineering Materials

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Metals - An Introduction

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we are going to explore the classification of engineering materials, starting with metals. Can anyone tell me the two main types of metals?

Ferrous and non-ferrous metals?

Correct! Ferrous metals contain iron, like steel and cast iron, while non-ferrous metals do not, such as aluminum and copper. Metals are known for their excellent conductivity and strength. To remember the categories of metals, you can use the mnemonic 'F-NM' for Ferrous-Non-ferrous Metals.

And what are some applications of these metals?

Great question! Metals are widely used in construction, automotive, and aerospace industries due to their durability and strength. Let's move on to polymers.

Polymers - Understanding Plastics

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Who can explain what polymers are and their characteristics?

Polymers are made of long chains of molecules and can be thermoplastics or thermosets.

Exactly! Thermoplastics can be reshaped with heat, while thermosets set permanently once formed. They are lightweight and resistant to corrosion. A good example is PVC used in plumbing.

What about other applications of polymers?

They are also used in packaging, insulation, and many structural parts. Remember: 'Lightweight and adaptable,' when thinking of polymers.

Ceramics - Hard Yet Brittle Materials

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let’s talk about ceramics. Can anyone share their properties?

They are hard and brittle, right?

Correct! Ceramics are inorganic and non-metallic, often used for their high-temperature resistance. They are found in items like tiles and cutting tools.

Is it true they are not very tough?

Yes, ceramics are excellent in hard applications but lack ductility, which means they can crack under stress. Remember: 'Hard but brittle' for ceramics.

Composites - The Best of Both Worlds

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Lastly, let's cover composites. What makes them special?

They combine materials to enhance certain properties.

Exactly! Composites, like fiberglass, offer superior strength-to-weight ratios. They're vital in aerospace and sports applications. To remember, think 'Composite = Combine + Ideal Performance.'

Can you give an example of their use?

Sure, they are commonly used in airplane wings. Let's recap: metals are strong, polymers are light, ceramics are hard, and composites combine strength and lightness.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Engineering materials are classified into four main categories: metals (ferrous and non-ferrous), polymers (thermoplastics and thermosets), ceramics, and composites. Each category has unique properties and diverse applications, making them essential in various industries.

Detailed

Classification of Engineering Materials

The classification of engineering materials is crucial for understanding their properties and applications in design and manufacturing. Engineering materials can be categorized into four primary groups:

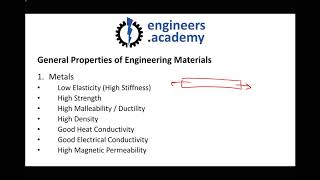

- Metals:

- Ferrous metals (such as steel and cast iron) and non-ferrous metals (like aluminum, copper, and titanium).

- Metals possess good electrical and thermal conductivity along with high strength, making them suitable for construction, automotive, and aerospace applications.

- Polymers:

- Thermoplastics (e.g., polyethylene and PVC) and thermosets (such as epoxy and bakelite).

- They are generally lightweight, corrosion-resistant, and have low thermal conductivity, and find uses in packaging, insulation, and structural components.

- Ceramics:

- These are inorganic, non-metallic solids, including alumina, silica, and zirconia.

- Recognized for their high hardness, brittleness, and resistance to high temperatures, ceramics are used in cutting tools, electrical insulators, and tiles.

- Composites:

- These materials consist of two or more components, like fiberglass and carbon fiber composites, which offer superior strength-to-weight ratios.

- Applications include aerospace components, automotive parts, and sports equipment.

Additionally, the section discusses the relevant properties of materials such as physical, mechanical, thermal, electrical, and chemical properties, alongside criteria for material selection and the use of Ashby diagrams for comparing materials efficiently.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Overview of Engineering Materials

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Engineering materials are broadly classified into the following categories:

Detailed Explanation

This introductory sentence sets the stage for understanding the various types of materials used in engineering. It indicates that the classification will encompass all the materials used in the field, offering a systematic way to categorize them based on their properties and applications.

Examples & Analogies

Think of engineering materials like ingredients in a recipe. Just as a chef selects different ingredients for their specific properties—like taste, texture, and appearance—engineers choose materials based on their unique attributes for different applications.

Metals

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

a. Metals

● Ferrous (e.g., steel, cast iron) and Non-ferrous (e.g., aluminum, copper, titanium)

● Good electrical and thermal conductivity, high strength

● Applications: construction, automotive, aerospace

Detailed Explanation

Metals are divided into two main categories: ferrous and non-ferrous. Ferrous materials contain iron, which makes them very strong, while non-ferrous metals do not contain iron, offering advantages like lower weight and improved corrosion resistance. Metals are known for their excellent conductivity and strength, making them essential in industries like construction and aerospace where these properties are critical.

Examples & Analogies

Imagine building a bridge. Engineers choose steel (a ferrous metal) for its strength to support heavy traffic. On the other hand, aluminum (a non-ferrous metal) might be used in aircraft structures to reduce weight while maintaining strength.

Polymers (Plastics)

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

b. Polymers (Plastics)

● Thermoplastics (e.g., polyethylene, PVC) and Thermosets (e.g., epoxy, bakelite)

● Lightweight, corrosion-resistant, low thermal conductivity

● Used in packaging, insulation, and structural parts

Detailed Explanation

Polymers are synthetic materials that are primarily made up of long chains of molecules. They can be classified into thermoplastics, which can be melted and reshaped, and thermosets, which permanently harden after being set. Polymers are known for their low weight and resistance to corrosion, making them ideal materials for a wide range of applications, from packaging materials to insulation in buildings.

Examples & Analogies

Think of thermoplastics as playdough—moldable and can take different shapes after being heated. In contrast, thermosets are like a baked cake—you can't reshape it once it's cool! For instance, PVC is commonly used for pipes, while epoxy is used in adhesives and coatings.

Ceramics

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

c. Ceramics

● Inorganic, non-metallic solids (e.g., alumina, silica, zirconia)

● High hardness, brittle, high-temperature resistance

● Applications: cutting tools, electrical insulators, tiles

Detailed Explanation

Ceramics are materials that are typically hard and brittle. They include compounds like alumina and silica, which are well-known for their hardness and ability to withstand high temperatures. However, ceramics can break easily under stress. Due to these properties, they are often used in specialized applications like cutting tools and insulators.

Examples & Analogies

Consider ceramic tiles in your home—they are tough and can handle high temperatures, which is why they’re excellent for flooring and kitchens. But just like a fine china cup, they can chip or break if dropped.

Composites

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

d. Composites

● Combination of two or more materials (e.g., fiberglass, carbon fiber composites)

● Superior strength-to-weight ratio

● Used in aerospace, automotive, and sports equipment

Detailed Explanation

Composites are made by combining two or more different materials to achieve desirable properties, such as increased strength and reduced weight. Fiberglass and carbon fiber are common examples. These materials exhibit impressive performance characteristics, making them ideal for applications where weight savings are vital, such as in cars and aircraft.

Examples & Analogies

Imagine a sandwich: the bread (one material) is sturdy, while the filling (another material) provides flavor. Together, they create a delicious, satisfying meal. Similarly, carbon fiber composites provide the strength of metals without the weight, like using a lightweight sandwich to fuel an athlete's performance.

Key Concepts

-

Metals: Ferrous and non-ferrous categories with conductive properties.

-

Polymers: Thermoplastics and thermosets, lightweight and adaptable.

-

Ceramics: Inorganic, hard, and brittle materials used for high-temperature applications.

-

Composites: The combination of materials giving rise to superior properties like strength-to-weight ratio.

Examples & Applications

Steel (ferrous) used in construction due to its strength.

PVC (thermoplastic) used in piping systems for its resistance to corrosion.

Alumina ceramic used in cutting tools for its hardness and wear resistance.

Fiberglass composite used in boat building for its lightweight and strength.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Metals are strong, and polymers are light, ceramics are hard but brittle in sight.

Stories

Imagine a building where metals hold the structure, polymers insulate, and ceramics tile the floor, while composites create the futuristic design!

Memory Tools

M-P-C-C: Metals, Polymers, Ceramics, Composites.

Acronyms

TMCT

Thermoplastics

Metals

Composites

Thermosets.

Flash Cards

Glossary

- Ferrous Metals

Metals that contain iron, such as steel and cast iron.

- NonFerrous Metals

Metals that do not contain iron, such as aluminum and copper.

- Polymers

Substances made of long chains of molecules, categorized into thermoplastics and thermosets.

- Thermoplastics

Polymers that can be soft and moldable when heated and solidify upon cooling.

- Thermosets

Polymers that irreversibly cure after being molded or heated.

- Ceramics

Inorganic, non-metallic solids known for hardness and brittleness.

- Composites

Materials made from two or more constituent materials with different physical or chemical properties.

Reference links

Supplementary resources to enhance your learning experience.