Control Volume Analysis

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Momentum Flux Correction Factors

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we'll explore the importance of momentum flux correction factors in fluid mechanics. Can someone explain what momentum flux is?

Isn't momentum flux related to the mass flow rate and velocities in a fluid?

Exactly! Momentum flux is the product of mass flow rate and velocity. Now, what's the issue with using average velocity in calculations?

It could lead to incorrect results if the velocity distribution isn't uniform.

Right! That's where the correction factor, beta, comes into play. In laminar flow, beta can be around one-third. Can anyone remember why that is significant?

It means the momentum flux is only a third when using average velocities!

Great job! So, in comparison, what happens in turbulent flow?

Beta tends toward 1, indicating a more uniform velocity distribution.

Exactly! Remember, Beta values signify how well our average velocity estimates the true momentum flux. Let's summarize: momentum flux correction factors adjust for non-uniform velocity distributions, and they vary significantly between laminar and turbulent flows.

Application in Sluice Gates

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, we’ll look at sluice gates. Why might we want to calculate the force required to hold a sluice gate in place against the flowing water?

To ensure it doesn’t open unexpectedly due to the pressure forces!

Exactly! We calculate this using hydrostatic pressure principles. Can anyone tell me how we derive that force mathematically?

We need to apply mass conservation and the momentum equation!

Correct! Mass influx equals mass outflux, which we can simplify using the control volume approach. If we know the flow depth and velocity, we can find the force on the gate. Let's compute an example using the values: h1 = 10m, h2 = 3m, and average velocity V1 = 1.5m/s.

How does shear stress come into play here?

Good question! In this context, shear stress is often negligible because the pressure and momentum forces dominate. It highlights the significance of simplifying assumptions in control volume methods. Let's summarize: hydrostatic pressure calculations and conservation of momentum allow us to determine the forces acting on sluice gates effectively.

Pressure Distribution in Control Volume

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's discuss how pressure distribution affects flow in our control volume analysis. What kind of assumptions do we make about pressure in a control volume?

We often assume hydrostatic pressure when flow is steady and at rest conditions.

Right! And why do we refer to pressure distributions as hydrostatic in such cases?

Because they act as if the fluid is at rest, allowing us to treat the pressure at the surface uniformly!

Exactly! When streamlines are parallel, our calculations simplify significantly. How does this relate to our previous discussions on shear stress in these scenarios?

If the pressure affects the flow more than shear stress, we can ignore shear effects.

Spot on! Assuming hydrostatic pressure helps us significantly simplify the mathematics in control volume analysis. Let’s recap: Hydrostatic pressure distributions apply when streamlines are parallel, allowing simplification of force calculations.

Practical Applications of Control Volume Analysis

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let's apply what we've learned through some practical examples involving control volume analysis. Can anyone share a scenario where this concept is crucial?

How about analyzing forces on a flat plate when hit by a water jet?

Great example! When a jet impacts a surface, we can use the conservation of momentum principles. What are the key factors we need to consider?

The velocity, area of the jet, and density of the fluid!

Correct! We need to account for the change in momentum to find the force acting on the plate. This relates back to our earlier discussions on applying mass conservation and momentum equations. Can anyone summarize this process?

We measure the incoming momentum of the jet and the rate at which it flows out, adjusting for density and area to calculate the resulting force!

Precisely! Such real-world scenarios highlight the utility of control volume analysis. Remember, making the right assumptions is key to solving these problems effectively.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section examines the significance of control volume methods used in fluid mechanics. It introduces momentum flux correction factors, detailing how average velocity comparisons can influence the calculation of forces on objects like sluice gates, along with the underlying principles of laminar and turbulent flows.

Detailed

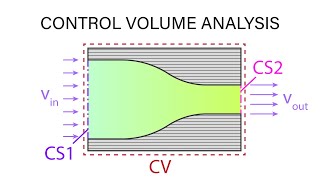

Control Volume Analysis

Control volume analysis is a fundamental approach in fluid mechanics that helps in understanding the momentum and energy interactions in flow systems. This section delves into two important concepts: momentum flux correction factors and the application of control volume analysis in practical scenarios, such as the impact on structures like sluice gates.

We begin by discussing the notion of momentum flux correction factors, which compensate for non-uniform velocity distributions in fluids. For instance, in laminar flow, where velocity distributions are known, the correction factor (denoted as beta) is significantly lower than in turbulent flow. For turbulent flows, beta approaches 1, indicating a nearly uniform distribution.

The section elaborates on how to derive the horizontal force required to maintain a sluice gate against fluid flow using hydrostatic pressure distribution principles and conservation of mass and momentum techniques. Key assumptions, such as neglecting shear stress due to its minimal impact compared to pressure forces, are emphasized.

Various problems illustrate the application of control volume analysis to determine forces acting on gates and jet impacts, reinforcing the importance of the pressure distribution and momentum conservation equations in problem-solving within fluid mechanics.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Momentum Flux Correction Factor Concept

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

And once I know this area and once I apply these things to the momentum flux correction factor equations, I will have this far.

To do these integrations, we can consider y = 1 @ r = 0, y = 0 @ r = R. So we will change this upper limit and lower limit of the equations when we are converting from dr to the y integrations. So, this is what, 0 to 1, the -1 components are there, -y square will be there.

And if you substitute these values, and you will get it one by third. So, in laminar flow case whatever this velocity distributions, the beta factor is called, comes to what one by third. That means, if you are computing the momentum flux using these average velocities, the actual momentum flux going through that surface following these velocity distributions, will be one third of that.

Detailed Explanation

The momentum flux correction factor (beta) is a key concept in fluid dynamics, especially in laminar flow where the velocity profiles can be non-uniform. When we derive the velocity distribution across a cross-section of flow, we find that in laminar flow, the average velocity tends to underestimate the actual momentum flux. For instance, when we integrate the velocity profile, we find that beta equals 1/3, suggesting that the actual momentum flux through a surface is one third of what it would be using only the average velocity. This emphasizes the need to account for non-uniform velocity distributions when analyzing fluid systems.

Examples & Analogies

Imagine trying to gauge the flow of syrup through a narrow opening in a container. If you just measured how fast the syrup can flow at one point, you might think it flows more smoothly than it actually does. However, because of viscous forces, the syrup flows slower near the edges, and your single point measurement would underestimate the total momentum (the 'push' of the syrup arriving at a surface). Understanding how syrup behaves in such scenarios helps one realize the importance of more refined measurements, just like the momentum flux correction factor in fluid flow.

Understanding Hydraulic Forces on a Sluice Gate

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Now, let us come to the second example, which is a sluice gate controlling flow in open channels. At sections 1 and 2, the flow is uniform and the pressure is hydrostatic. Neglecting bottom friction and atmospheric pressure, derive a formula for the horizontal force F required to hold the gate. Express your final formula in terms of the inlet velocity V, eliminating V2. Compute the force acting on the gate if h1 = 10m, h2 = 3m and V1 = 1.5m/s.

Detailed Explanation

In this example, we analyze fluid flow over a sluice gate. We need to derive a formula for the horizontal force required to keep the gate in place against the flow of water. The basic approach includes applying pressure principles—considering hydrostatic pressure distributions related to the depths of fluid h1 and h2 on either side of the gate. The force on the gate can be related to pressure differences due to head (vertical depth of fluid), and the steady flow equations will allow us to express the net force in terms of velocity and depth, minimizing the complexity of the calculation by eliminating certain variables.

Examples & Analogies

Think of a water-filled swimming pool with a large gate at one end. When the water level rises, it pushes against the gate. The deeper the water (like h1 being greater than h2), the more pressure it creates pushing against that gate. If you've ever tried to hold a heavy door when wind pushes against it, you know that sometimes you have to apply more force to combat pressure. That’s similar to what happens with the sluice gate, where water pressure needs to be considered to determine how much force is needed to hold the gate.

Application of Mass Conservation

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Now I will apply mass conservation equation, because of a single inlet and outlet conditions, the mass influx is equal to mass outflux. Outflow = Inflow. So, you know, h1, h2 you can consider a unit width perpendicular to the surface then the V will be cancelled out or you can V width, then you can compute the what will be the velocity.

Detailed Explanation

Mass conservation is a fundamental principle stating that in a closed system, mass cannot be created or destroyed. In fluid mechanics, this principle can be applied to analyze flow where a fluid enters and exits a control volume—a defined space through which fluid flows. In our case, for a sluice gate, the mass being removed from the inlet equals the mass exiting the outlet. By simplifying assumptions (for instance, considering uniform flow and using unit widths), we can easily calculate how the heights of the fluid fill (h1 and h2) relate to the velocities of the fluid at different points, illustrating the flow behavior through the gate.

Examples & Analogies

Think about pouring water from a pitcher into a glass—what enters the glass (mass from the pitcher) must equal what is in the glass; if no water is lost, the water levels reflect this balance perfectly. It’s similar to ensuring that the water flow going in through a sluice gate equals the flow coming out. This balance helps engineers make predictions about how gates should be designed, ensuring they are effective for controlling water flow.

Pressure and Momentum Forces in Control Volumes

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Now, applying the Reynolds transport theorem, some of the force acting on this will be the rate of change of the momentum flux storage within the control volume, and net outflux of the momentum flux, considering this V values.

Detailed Explanation

Applying the Reynolds Transport Theorem allows us to relate forces acting on a control volume (like our sluice gate) to the changes in momentum within that volume. When a flow impacts an element in the gate area, the change in momentum—defined as momentum flux—can be calculated by examining how the mass and velocity of water entering and exiting the control volume change over time. This analytical approach provides critical insights into how forces develop due to fluid motion, allowing for better designs and safety measures in hydraulic structures.

Examples & Analogies

Similar to how the force you exert when trying to catch a ball depends on the momentum of the ball and its velocity, the forces at play on the sluice gate relate directly to how fast water enters and exits the gate area. Picture trying to catch a very fast-moving soccer ball—your hands would experience a strong force equal to the ball's momentum. In hydraulics, understanding where and how momentum changes can help predict forces on structures like gates.

Key Concepts

-

Momentum Flux: A measure of momentum transfer per unit area.

-

Correction Factor: Adjusts for velocity distribution variances.

-

Hydrostatic Pressure: Pressure exerted by static fluids, important for force calculations.

Examples & Applications

Calculating forces on a sluice gate using hydrostatic pressure principles.

Analyzing the impact of a water jet on a flat plate.

Determining momentum forces in steady flow conditions.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

When flow’s not the same, beta’s to blame; it adjusts the pace, in this learning race.

Stories

Imagine a sluice gate standing strong against a rushing river. It’s the force of hydrostatic pressure that holds it in place, while momentum beings and flows speed right past without losing their shape.

Memory Tools

Use the acronym HPM (Hydrostatic Pressure Momentum) to remember: H for Hydrostatic, P for Pressure, and M for Momentum calculations.

Acronyms

BETA

Buffering Estimates for Turbulent Analysis.

Flash Cards

Glossary

- Momentum Flux

The product of mass flow rate and fluid velocity, representing the quantity of momentum crossing a unit area per unit time.

- Correction Factor (Beta)

A factor applied to account for non-uniform velocity distribution in fluid flow, particularly important in momentum calculations.

- Hydrostatic Pressure

The pressure exerted by a fluid at rest, proportional to the depth of the fluid and independent of the shape of the container.

- Control Volume

A defined region in space through which fluid can flow, used for analyzing fluid dynamics and applying conservation principles.

Reference links

Supplementary resources to enhance your learning experience.