Introduction to Gears

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Definition and Role of Gears

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Hello class! Today, we're going to explore gears. Can anyone tell me what they think gears are?

Are gears those round things that help machines move?

Exactly! Gears are toothed mechanical elements that transmit motion and power between rotating shafts, essential in many machines for achieving specific speed and torque ratios.

Why are they important in precision applications?

Great question! Gears provide a positive, non-slip drive, ensuring accurate motion transmission, which is crucial in precision applications like watches or automotive systems. Remember, *Gears = Motion + Precision*! Let's move on to the types of gear profiles.

Gear Tooth Profiles

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we'll look at gear tooth profiles. Who can tell me about the involute profile?

Isn't it the most commonly used gear profile?

Correct! The involute profile maintains a constant velocity ratio even with slight errors in the center distance, making it easy to manufacture and analyze. Now, can anyone explain the cycloidal profile?

It’s used in watches and clocks, right? But doesn’t it have less tolerance for center distance variation?

Yes, well done! Remember, for gears, *Involute is common, Cycloidal is precise*!

Key Gear Parameters

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's delve into key gear parameters. What is a pitch circle?

Isn’t that the imaginary circle where gear teeth interact?

Exactly! Now, who can tell me what the term 'module' refers to?

It's the ratio of the pitch diameter to the number of teeth, right?

Spot on! Remember this: *Pitch is where teeth meet, Module is fit for the fleet*! Now let’s move on to pressure angle and other parameters.

Fundamental Laws of Gearing

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, we’ll discuss the Fundamental Law of Gearing. Who can summarize it?

The common normal at the point of contact must pass through the pitch point to maintain a constant angular velocity ratio.

Precisely! This ensures conjugate action, which is crucial for the function of gears. Remember: *Law of Gearing = Consistency in Motion*! Good, now let’s address contact ratio and interference.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

In this section, we explore the definition and importance of gears, their tooth profiles, and parameters. We also cover fundamental concepts related to gear operation, types of gears, gear trains, and force analysis, setting a foundation for understanding their role in mechanical systems.

Detailed

Introduction to Gears

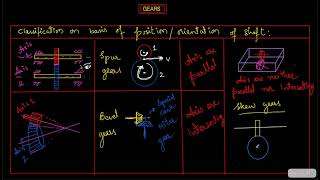

Gears are toothed mechanical elements used to transmit motion and power between rotating shafts, adhering to specific speed and torque ratios. Their ability to provide positive, non-slip drive makes them suitable for precision applications. This introductory section outlines the characteristics, profiles, and parameters of gears, such as the involute and cycloidal profiles, which ensure constant velocity ratios during operation. Furthermore, we explore critical gear parameters including pitch circle, module, pressure angle, addendum, dedendum, and backlash. The fundamental law of gearing illustrates the necessity of maintaining a constant angular velocity ratio through conjugate action. Various types of gears are introduced, such as spur, helical, bevel, worm gears, and rack and pinion arrangements, followed by an explanation of gear trains. Finally, the section discusses force analysis and the importance of computer-aided simulation in modern gearbox design.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Definition of Gears

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Gears are toothed mechanical elements used for transmitting motion and power between rotating shafts with specific speed and torque ratios.

Detailed Explanation

Gears are mechanical devices that have teeth (or cogs) which mesh together to transmit motion and force from one part of a machine to another. When two gears are connected, the rotation of one gear causes the other gear to turn as well. This transmission allows us to change the speed and torque of the motion. Speed refers to how fast the shaft rotates, while torque refers to the force that the gear can exert. Gears are designed to work in pairs, and they can alter these parameters according to their design.

Examples & Analogies

Think of gears like a bicycle's gears. When you shift gears while pedaling, you change the mechanical advantage, allowing you to pedal easier uphill (greater torque) or go faster on flat ground (greater speed).

Positive, Non-slip Drive

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

They provide positive, non-slip drive, making them ideal for precision applications.

Detailed Explanation

A positive drive means that the motion is reliably transferred from one gear to another without slipping. This is crucial in applications where precise movement is necessary, such as in clocks or robotics. The non-slip nature of gears ensures that the output remains consistent regardless of the load applied, which is vital in achieving accuracy in performance.

Examples & Analogies

Imagine a well-calibrated clock. If the gears inside were to slip, the clock would not keep accurate time. Gears ensure that every tick is consistent, just like a perfectly timed watch.

Key Concepts

-

Gears: Mechanical elements that transmit motion and power.

-

Involute Profile: Most commonly used tooth profile that maintains a constant velocity ratio.

-

Pitch Circle: The imaginary circle where gear teeth engage.

-

Fundamental Law of Gearing: Ensures constant angular velocity ratio through conjugate action.

Examples & Applications

A car's transmission system uses helical gears to provide smoother operation.

Watches utilize cycloidal gears for high precision in timekeeping.

Memory Aids

Interactive tools to help you remember key concepts

Acronyms

GAP

Gear

Addendum

Pitch – key elements to remember!

Flash Cards

Glossary

- Pitch Circle

Imaginary circle where gear teeth interact.

- Module (m)

Ratio of pitch diameter to the number of teeth.

- Pressure Angle (ϕ)

Angle between the tooth profile and the line of action.

- Addendum

Radial distance from the pitch circle to the top of the tooth.

- Dedendum

Radial distance from the pitch circle to the root of the tooth.

- Backlash

Clearance between mating gear teeth.

- Contact Ratio

Average number of teeth in contact at any time.

- Interference

Occurs when non-conjugate portions of teeth interfere.

- Spur Gears

Gears with parallel shafts, simplest and most common type.

- Helical Gears

Gears with angled teeth, providing smoother and quieter operation.

Reference links

Supplementary resources to enhance your learning experience.