Springs

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Springs

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today we're diving into springs! Can anyone tell me what springs do in machines?

They help absorb shocks, right?

And also store energy!

Exactly! Springs are vital for energy storage and shock absorption. Remember the acronym *SAS* - Springs Absorb Shocks. Let's explore the different types of springs.

What types of springs are there?

Great question! We have helical compression springs, tension springs, torsion springs, and leaf springs. Each has specific functions. For example, helical compression springs resist compressive forces while leaf springs are found in vehicle suspensions.

Why is the type of spring important?

The type determines their performance and application, which is crucial for machine design. Let's summarize this session: springs are essential components defined by their ability to absorb shocks and store energy, categorized mainly into four types.

Design Considerations for Springs

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's look at some important design considerations when it comes to springs. What do you think influences a spring's performance?

Maybe how stiff it is?

Absolutely! Spring stiffness and deflection are crucial. The more the spring is compressed or stretched, the more force it can exert. Remember *SSD* - Spring Stiffness and Deflection!

What about shear stress?

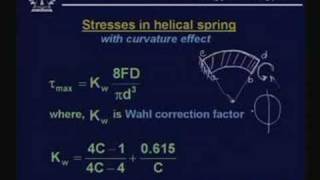

Good point! The shear stress in coils can determine the spring's lifespan. If the stress is too high, it could lead to failure. Also, we consider the Wahl correction factor to accurately calculate the stress.

And fatigue failure? I’ve heard that mentioned.

Very important to understand! Springs are vulnerable to fatigue failure under fluctuating loads. It's crucial to design springs that can withstand these conditions over time without failing.

So, we have to be aware of these factors to design effective springs?

Exactly! In summary, when designing springs, we must consider stiffness, shear stress, correction factors, and fatigue. Understanding these elements is key to creating reliable machine components.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Springs play a vital role in mechanical systems by storing energy and absorbing shock. This section details various types of springs, their design considerations such as stiffness and fatigue, and the importance of understanding these elements for effective machine design.

Detailed

Springs

Springs are essential mechanical components utilized across numerous industries. They serve the purpose of storing energy, absorbing shocks, and maintaining force between surfaces in contact. Key types of springs include:

- Helical Compression Springs: Designed to resist compressive forces.

- Helical Tension Springs: Built to withstand stretching or tensile forces.

- Torsion Springs: Engineered to resist rotational loading.

- Leaf Springs: Commonly found in vehicle suspension systems.

Design Considerations

When designing springs, several factors need careful consideration:

- Spring Stiffness and Deflection: Interrelates to how much a spring will deform under a load.

- Shear Stress in Coils: Critical for evaluating the durability and lifespan of the spring.

- Wahl Correction Factor: Adjusts the theoretical calculations of spring stress due to geometry.

- Fatigue Failure under Fluctuating Loads: Understanding this helps predict a spring's lifespan and performance under varying conditions.

Overall, the analysis and design of springs are crucial for ensuring reliability and performance in mechanical systems.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to Springs

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Springs are used to store energy, absorb shock, or maintain force between contacting surfaces.

Detailed Explanation

Springs are mechanical devices that can be compressed, stretched, or twisted to store and release energy. They play a crucial role in many mechanical systems by providing force or impact absorption. For example, when you jump on a trampoline, the springs absorb your weight and then push you back up, demonstrating energy storage and force maintenance.

Examples & Analogies

Think of a spring as a rubber band: when you stretch it, it stores energy, and when you release it, that energy is released, causing it to return to its original shape. Trampolines are like advanced rubber bands, using springs to help bounce you back into the air.

Types of Springs

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

a. Types of Springs:

● Helical Compression Springs – resist compressive forces

● Helical Tension Springs – resist stretching/tensile forces

● Torsion Springs – resist rotational loading

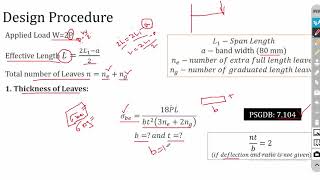

● Leaf Springs – used in vehicle suspensions

Detailed Explanation

Springs come in various types, each designed for specific applications. Helical compression springs are coiled and designed to be compressed, while helical tension springs are also coiled but meant to be stretched. Torsion springs work by twisting, providing resistance to rotational forces. Leaf springs are flat and primarily used in vehicle suspensions for load distribution and shock absorption.

Examples & Analogies

Imagine different types of springs as different tools in a toolbox: a helical compression spring is like a plunger that pushes back when you compress it, a helical tension spring is like a rubber band that stretches to pull things together, a torsion spring is like a twisty toy that returns to its original shape when twisted, and a leaf spring is like a flat board that bends under pressure, like in a car's suspension system.

Design Considerations for Springs

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

b. Design Considerations:

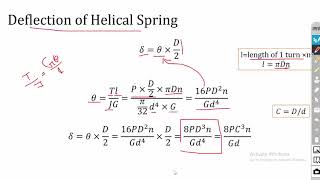

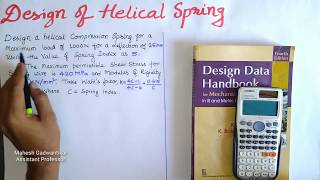

● Spring stiffness and deflection

● Shear stress in coils

● Wahl correction factor

● Fatigue failure under fluctuating loads

Detailed Explanation

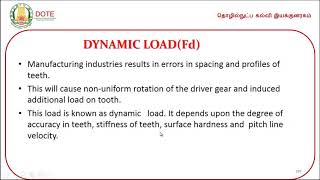

Designing springs involves understanding key factors that affect their performance. Spring stiffness determines how much load a spring can handle without deforming. Deflection refers to how much a spring compresses or extends when a load is applied. Shear stress occurs in the coils of the spring, and it's critical to consider to prevent failure. The Wahl correction factor is used to adjust theoretical calculations to account for real-world behavior. Lastly, fatigue failure can occur due to repeated loading and unloading, which can lead to spring failure over time.

Examples & Analogies

Designing a spring is like creating a new chair. You need to consider how strong the chair needs to be (stiffness), how much it will bend when someone sits down (deflection), and ensure it won't break under regular use (fatigue). The Wahl correction factor ensures you adjust the chair's design based on how people actually use it, similar to how engineers fine-tune springs for optimal performance.

Key Concepts

-

Types of Springs: Include helical compression, tension, torsion, and leaf springs, each serving specific functions.

-

Design Considerations: Important factors like spring stiffness, shear stress, Wahl correction factor, and fatigue failure which influence spring performance.

Examples & Applications

Compression springs used in pens and shock absorbers that store and release energy.

Tension springs found in garage doors to assist in lifting.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

When springs are in compression, strength is their mission!

Stories

Once there was a leaf spring named Larry who helped cars jump over bumps, spreading joy as he cushioned rides.

Memory Tools

For springs remember SAM: Store energy, Absorb shocks, Maintain force.

Acronyms

SPRINGS

Storing Power

Resisting Instability

Navigating Gravity Sustainably.

Flash Cards

Glossary

- Helical Compression Springs

Springs designed to resist compressive forces.

- Helical Tension Springs

Springs that resist stretching or tensile forces.

- Torsion Springs

Springs that resist rotational loading.

- Leaf Springs

Springs used in vehicle suspensions.

- Spring Stiffness

The resistance of a spring to deformation under load.

- Shear Stress

The stress that occurs when a force is applied parallel to the surface.

- Wahl Correction Factor

A factor used to account for geometric effects in spring stress calculations.

- Fatigue Failure

Failure that occurs after repeated loading and unloading.

Reference links

Supplementary resources to enhance your learning experience.