Material Compatibility

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Importance of Material Compatibility

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we’re going to discuss material compatibility. Why do we think it’s important for integrating lasers with other optoelectronic devices?

Maybe because different materials behave differently under electrical or optical signals?

Exactly! Different semiconductor materials, like Gallium Arsenide and Indium Phosphide, have unique properties that affect the integration process.

So, if the materials aren't compatible, could that break the whole system?

Yes, it can lead to poor performance or even failure. That’s why understanding semiconductor materials is crucial.

Semiconductor Materials

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s explore semiconductor materials used in lasers. Can anyone name a few materials?

I know Gallium Arsenide is one of them!

Correct! GaAs is widely used for laser diodes. What about Indium Phosphide?

Isn't that used for fiber optics?

Yes! And both materials have different efficiencies and wavelength ranges. Remember, the choice impacts how they perform in integrated systems!

Hybrid Integration Methods

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s talk about hybrid integration. What do you think it means?

Maybe combining different materials in one system?

Exactly! Hybrid integration allows for the use of various materials for different components. Can you give an example?

Like using one material for the laser and another for the photodetector, right?

Spot on! Methods like flip-chip bonding help in effectively integrating those materials while maintaining performance.

Consequences of Poor Compatibility

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

What do you think could happen if we ignore material compatibility?

Maybe the system would overheat or not work at all?

Yes! Overheating is one consequence, but we could also face reduced efficiency and lifespan of the devices involved.

So ensuring materials are compatible helps prolong the system's life?

Exactly! That’s why engineers work hard to ensure proper integration from the start.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Material compatibility is essential for the successful integration of lasers with electronic components, particularly when considerations regarding semiconductor materials, hybrid integration methods, and performance criteria are involved.

Detailed

Material Compatibility

Ensuring material compatibility is a crucial component in the integration of lasers with optoelectronic devices. Compatibility influences the performance, efficiency, and reliability of integrated systems that combine optical (like lasers) and electronic components (like photodiodes and LEDs). Key points in this section include:

Semiconductor Materials

Most lasers, especially laser diodes, utilize semiconductor materials such as Gallium Arsenide (GaAs) and Indium Phosphide (InP). The choice of these materials is vital as it dictates the wavelengths they can effectively produce, impacts their efficiency, and influences the overall integration techniques.

Hybrid Integration

Hybrid integration methods, such as flip-chip bonding or micro-optics, are often required when different materials are used for varying components. This approach allows for flexibility in design while also addressing material compatibility concerns.

The section emphasizes that without specific attention to these compatibility factors, the success of optoelectronic systems is jeopardized, affecting their overall functionality in fields ranging from telecommunications to sensors and beyond.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Importance of Material Compatibility

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

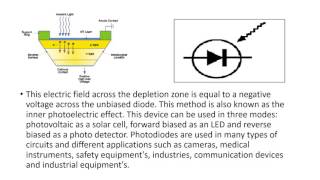

One of the most fundamental aspects of integrating lasers with other optoelectronic devices is ensuring that the materials used in the laser, photodiodes, and other components are compatible with each other.

Detailed Explanation

Material compatibility is essential because the performance of an optoelectronic device depends on the interaction between its components. When materials are compatible, they work well together, ensuring that energy transfer and signal transmission occur efficiently. This is especially important in systems where various components (like lasers and photodiodes) must function together seamlessly.

Examples & Analogies

Think of a sports team; if all players have different playing styles that don't mesh well together, the team won't perform effectively. However, if they train together and understand each other's strengths and weaknesses, they can win games. Similarly, compatible materials ensure that devices work better together.

Use of Semiconductor Materials

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Since lasers often require semiconductor materials like gallium arsenide (GaAs) or indium phosphide (InP), it’s crucial to use materials that can be efficiently integrated with the electronic components.

Detailed Explanation

Semiconductor materials play a vital role in the functionality of laser devices. For instance, gallium arsenide (GaAs) is commonly used because of its efficient light emission properties. It's essential to select semiconductor materials that not only fit the specific application but also work together with other materials in the system. This helps in maximizing performance and ensuring longevity of the devices.

Examples & Analogies

Consider a car engine; using the proper fuel is crucial for optimal performance. Using GaAs in lasers is like using high-quality fuel for a race car—the performance is maximized when the right materials are chosen.

Hybrid Integration Methods

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

In some cases, different materials are used for different optoelectronic components (e.g., separate materials for the laser source and photodetectors), and hybrid integration methods like flip-chip bonding or micro-optics may be employed.

Detailed Explanation

Hybrid integration involves combining different materials that may not be compatible in a straightforward way. This is essential because it allows the use of the best material for each component, like optimizing a laser for output while using another material that may be better for detection. Techniques like flip-chip bonding help connect these components securely without compromising their individual properties.

Examples & Analogies

Imagine assembling a high-performance computer where you mix various hardware from different brands (like a graphics card from one company and a motherboard from another). Each piece serves a unique function, and when combined correctly through hybrid integration, they create a robust, high-performance machine.

Key Concepts

-

Material Compatibility: The crucial requirement that different materials maintain performance when integrated.

-

Semiconductor Materials: Essential materials that play a pivotal role in the function of lasers and electronics.

-

Hybrid Integration: A technique allowing for flexibility in material usage within optoelectronic devices.

-

Flip-Chip Bonding: A method for directly connecting components to enhance performance.

Examples & Applications

Using Gallium Arsenide in laser diodes for telecommunications applications.

Implementing hybrid integration for a system that combines a laser source and different photodetectors.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

For lasers bright and circuits entwined, materials must be paired, or problems you'll find.

Stories

Imagine two friends, GaAs and InP. They want to create a laser together. If they don’t match their wavelengths, their project fails. This story highlights the importance of choosing materials wisely.

Memory Tools

To remember the steps for compatibility: 'MACM' - Materials, Applications, Compatibility, Method.

Acronyms

MICS for Material Integration Compatibility Strategy - focusing on Materials, Integration, Components, and Systems.

Flash Cards

Glossary

- Material Compatibility

The ability of different materials to function together in a system without compromising performance.

- Semiconductor Materials

Materials that have electrical conductivity between that of a conductor and an insulator, used in lasers and electronic devices.

- Hybrid Integration

A method which combines different materials and technologies to create integrated devices, allowing flexibility in design.

- FlipChip Bonding

A technique where the active side of one component is bonded directly to another component, facilitating signal transfer.

- MultiWavelength Operation

The ability of a laser or photodiode to operate at multiple wavelengths, often necessitating precise material integration.

Reference links

Supplementary resources to enhance your learning experience.