Pavement Materials and Their Stabilization

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Pavement Materials

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we are going to discuss the different types of pavement materials that form the foundation of road construction. Can anyone name a few types?

I think subgrade soil is one of them!

That's correct! Subgrade soil is essential. It acts as the base layer. Now, what about materials above it?

Granular sub-base, like GSB and WBM?

Exactly! GSB and Wet Mix Macadam are critical for improving drainage and load distribution. Remember, GSB stands for Granular Sub-base! What benefits do these materials provide?

They make the pavement stronger and more durable.

You've got it! Now, let’s summarize: we’ve covered subgrade soil, GSB, and WBM, which all contribute to a robust pavement structure.

Stabilization Techniques for Sub-base and Base Layers

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s dive into the idea of stabilization. Why do we need to stabilize materials like GSB and WMM?

To make sure they can handle the loads of traffic, right?

Correct! We use substances like cement, lime, and fly ash to boost their strength. Can anyone elaborate on the benefits?

It helps reduce the thickness of the pavement, making it lighter and cheaper!

Yes! It also improves load distribution and increases resistance to water damage. A mnemonic for this could be 'DWL' - reduced Thickness, Better Load distribution, and Water resistance. Knowing these can help when we design pavements.

Got it! DWL for benefits of stabilization.

Great! To recap, stabilization enhances performance and cost-effectiveness of pavement materials.

Additives Used for Stabilization in Bituminous Layers

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s focus on stabilized bituminous layers. What common materials are used?

I believe additives like polymers and rubber are used.

Exactly! These additives enhance performance by improving elasticity and resilience. Does anyone have a better understanding of why these properties matter?

They help in absorbing shocks and extending the lifespan of the pavement!

Perfect! Always remember that elasticity and resilience are key to sustainability. For summarization, we’ve reviewed the role of additives and their importance in enhancing bituminous layers.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section covers essential elements of pavement materials, including subgrades, granular sub-bases, and bituminous layers. It highlights the use of cement, lime, and fly ash for stabilization and discusses the benefits, such as reduced pavement thickness and improved load distribution.

Detailed

Pavement Materials and Their Stabilization

In highway engineering, the choice of pavement materials is critical for building durable and effective road structures. This section introduces the types of pavement materials, including subgrade soil, granular sub-base (GSB), and various bituminous layers like Water Bound Macadam (WBM) and Wet Mix Macadam (WMM). The stabilization techniques using cement, lime, and fly ash are emphasized as they enhance the performance of sub-base and base layers, leading to reduced thickness and improved water resistance. The section also touches on stabilized bituminous layers where additives like polymers and rubber are used to further strengthen pavement materials.

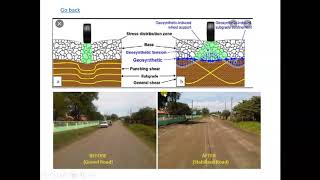

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to Pavement Materials

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

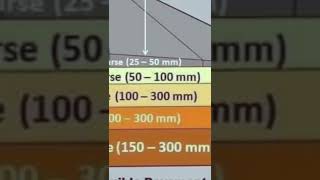

• Subgrade soil

• Granular sub-base (GSB)

• Water Bound Macadam (WBM)

• Wet Mix Macadam (WMM)

• Bituminous and cementitious layers

Detailed Explanation

This chunk introduces the different types of pavement materials used in construction. It lists:

1. Subgrade soil: This is the natural soil layer that serves as the foundation for the pavement. Its quality directly affects the stability of the road.

2. Granular sub-base (GSB): This layer is made of coarse aggregates that are placed over the subgrade to improve load distribution.

3. Water Bound Macadam (WBM): A type of base layer constructed with stone aggregates bound together with water, providing good drainage and strength.

4. Wet Mix Macadam (WMM): Similar to WBM but includes added water during mixing to enhance compaction.

5. Bituminous and cementitious layers: These are more refined and often include asphalt or cement to provide surface strength and longevity.

Examples & Analogies

Imagine building a house. You start with a solid foundation that will support the entire structure. Just like that foundation, subgrade soil and the other pavement materials listed here serve as a support system for roads. Each layer contributes to the overall strength and durability required to handle vehicles, much like how a robust foundation helps a house withstand weather and weight.

Stabilized Sub-base and Base Layers

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Use of cement, lime, and fly ash for GSB and WMM.

• Benefits:

– Reduced thickness of pavement.

– Improved load distribution.

– Higher resistance to water damage.

Detailed Explanation

This chunk discusses the stabilization of sub-base and base layers, focusing on the materials used and the benefits of stabilization.

- Materials Used: Cement, lime, and fly ash are commonly used stabilizers for granular sub-bases (GSB) and Water Mix Macadam (WMM). These materials help improve the properties of the base layers, making them more suitable for supporting loads.

- Benefits: Stabilization offers several advantages:

1. Reduced thickness of pavement — With stabilized materials, the need for thick pavement layers decreases, which can save costs.

2. Improved load distribution — Stabilized layers better distribute weight across the structure, enhancing overall road performance.

3. Higher resistance to water damage — By using materials like cement and lime, the layers become more resistant to water infiltration, reducing potential damage from moisture.

Examples & Analogies

Think about a sponge and a solid piece of cake. A sponge can easily break when under pressure, while a cake stands strong. In this analogy, the sponge represents unstabilized pavement that can buckle under heavy loads, especially when wet, while the cake symbolizes stabilized pavement that holds up well even under pressure. Using stabilizers like cement or lime is like making the sponge firmer and more resilient, ensuring it can bear weight effectively.

Stabilized Bituminous Layers

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Dense Bituminous Macadam (DBM)

• Bituminous Concrete (BC)

• Use of additives like polymers, rubber, and nano-materials.

Detailed Explanation

This chunk provides insight into stabilized bituminous layers used in road pavements.

1. Dense Bituminous Macadam (DBM): This is a type of strong asphalt used in surface layers to resist wear and provide a smooth ride.

2. Bituminous Concrete (BC): Also an asphalt-based layer that provides additional strength and durability to the pavement.

3. Additives: To enhance the properties of these asphalt layers, additives such as polymers, rubber, and nano-materials may be included. These additives improve elasticity, reduce cracking, and increase resistance to extreme temperatures.

Examples & Analogies

Consider how adding spices enhances the flavor of a dish. In road construction, just like herbs and spices improve food, additives like polymers and rubber improve the performance of bituminous layers. They ensure that the road can flex and withstand wear over time, making it more durable and less prone to damage, much like how a well-seasoned dish stands out.

Key Concepts

-

Pavement Materials: The essential components used in constructing pavements, including subgrade soil, granular sub-base, and bituminous layers.

-

Stabilization Techniques: Methods such as chemical or mechanical processes to enhance the properties of pavement materials, improving durability and performance.

-

Additives: Materials like cement, lime, and polymers that enhance the mechanical properties of pavement materials.

Examples & Applications

Cement stabilization is used for granular sub-base layers to increase compressive strength and load distribution.

Using polymers in bituminous layers improves flexibility and increases the lifespan of road surfaces.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

For roads that last, make them strong and fast! With GSB and WMM together cast.

Stories

Imagine a builder named Sam who crafted roads with layers: a soft bed of earth, topped with gravel and bits of rubber, making the streets strong against wear.

Memory Tools

Remember 'PaGS' for Pavement Materials: Pavement = Pa, Granular Subbase = GS.

Acronyms

DWL – Thickness, Water Resistance, Load distribution for stabilization benefits.

Flash Cards

Glossary

- Subgrade Soil

The native soil found beneath the pavement structure, working as the primary load-bearing layer.

- Granular Subbase (GSB)

A layer of coarse aggregates designed to improve pavement drainage and strengthen the load-bearing capacity.

- Wet Mix Macadam (WMM)

A dense mixture of aggregates combined with water and a binding agent used as a base or sub-base under pavements.

- Bituminous Layers

The layers of pavement made from asphalt material, which provides a flexible surface for roads.

Reference links

Supplementary resources to enhance your learning experience.