Stabilized Bituminous Layers

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Stabilized Bituminous Layers

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today we'll discuss stabilized bituminous layers, which are essential for ensuring road durability. Can anyone remember what we mean by 'stabilized'?

Does it mean making the bitumen stronger or more stable?

Exactly! Stabilizing bituminous layers helps them resist deformation under load. What are the two main types of these layers in pavements?

Dense Bituminous Macadam and Bituminous Concrete?

Correct! Let's remember DBM as 'Dense Base' and BC as 'Best Concrete' to retain their core meanings. Why are these layers important in pavement design?

To support the traffic loads?

Right! They need to withstand high traffic and harsh conditions. Today, we'll delve into each type.

Dense Bituminous Macadam (DBM)

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's explore Dense Bituminous Macadam. DBM is known for its density. What's one reason why its density is beneficial?

It probably helps in load distribution?

Precisely! A dense structure ensures effective load distribution, preventing deformation. Why do you think DBM is widely used?

Because it’s strong and supports heavy vehicles?

Exactly! It’s critical for high-load areas. Let’s remember DBM as a 'Densely Built Macadam.'

Bituminous Concrete (BC)

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's switch gears and talk about Bituminous Concrete. Who can explain what we mean by 'bituminous concrete'?

Is it a type of concrete that uses bitumen instead of water?

Good observation! While it's similar to concrete, it’s designed with bitumen for better performance in pavements. What’s one key advantage of BC?

I think it can hold more weight, making it safer for heavy traffic, right?

Right! High load-bearing capacity is why it’s often used in urban roads. Remember BC as 'Best Construction' for heavy-duty roads.

Additives in Stabilized Bituminous Layers

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's talk about additives – why do we use them with DBM and BC?

To improve their properties? Like making them last longer?

Exactly! Additives like polymers and rubber enhance flexibility and resistance to ruts. Can anyone think of one common additive?

Polymers? I’ve heard they can make roads more elastic.

Absolutely! We can think of additives using 'R-P-N' – Rubber, Polymers, and Nano-materials. They significantly improve road performance.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

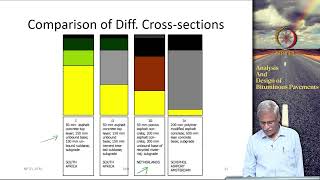

The section highlights the importance of stabilized bituminous layers in pavement systems, specifically Dense Bituminous Macadam (DBM) and Bituminous Concrete (BC). It details the additives used, including polymers, rubber, and nano-materials, to improve stability, durability, and performance characteristics under various traffic conditions.

Detailed

Stabilized Bituminous Layers

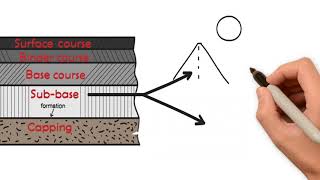

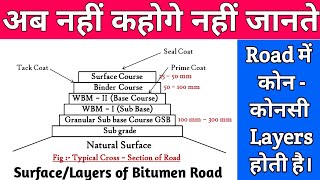

Stabilized bituminous layers are crucial components in flexible pavement design, aimed at enhancing durability and performance. This section focuses on two main types of these layers:

- Dense Bituminous Macadam (DBM): This layer is characterized by being dense and well-graded, forming a strong base that supports the surface layer and resists deformation.

- Bituminous Concrete (BC): Designed for higher load-bearing capacities, BC provides superior surface quality and performance, making it suitable for high-traffic areas.

To improve the characteristics of these layers, various additives are utilized:

- Polymers: Enhance flexibility and adhesion.

- Rubber: Improves elasticity and resistance to ruts.

- Nano-materials: Provide advancements in material technology, leading to enhanced strength and performance.

The integration of these materials results in pavement layers that offer enhanced moisture resistance, reduced cracking, and extended service life, contributing significantly to the overall effectiveness and longevity of pavement structures.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Dense Bituminous Macadam (DBM)

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Dense Bituminous Macadam (DBM)

Detailed Explanation

Dense Bituminous Macadam (DBM) is a type of surface layer material used in road construction. It involves using finely graded aggregates mixed with a binder, usually bitumen, to provide a durable and strong surface. DBM is designed to withstand heavy traffic and varying environmental conditions. Its density helps in providing a strong and stable foundation that minimizes deformation under load.

Examples & Analogies

Think of DBM like a tough, resilient shell for a hard-boiled egg. Just as the shell protects the egg inside, DBM protects the underlying layers of the road from wear and tear while offering a smooth driving surface.

Bituminous Concrete (BC)

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Bituminous Concrete (BC)

Detailed Explanation

Bituminous Concrete (BC) is another form of pavement material made from a mixture of aggregates, binder, and fillers. The technology used in BC allows for a high-quality, durable surface that can tolerate traffic loads and resist water damage. It generally has improved qualities in terms of flexibility and resistance to deformation compared to unbound materials.

Examples & Analogies

Imagine BC as the protective coating on a smartphone. Just as the screen protector helps the phone endure drops and scratches, BC provides a tough layer over the road, protecting it from the damage caused by vehicles and weather conditions.

Additives Used in Stabilization

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Use of additives like polymers, rubber, and nano-materials.

Detailed Explanation

To enhance the performance of stabilized bituminous layers, various additives such as polymers, rubber, and nano-materials are incorporated. These additives improve the elasticity and resilience of the bituminous materials, making them more resistant to cracking and deformation under stress. For example, polymers can make the pavement more flexible, allowing it to better absorb impacts from traffic.

Examples & Analogies

Consider the difference between basic dough and dough with added ingredients like eggs or yogurt. The additional ingredients make the dough richer and more pliable. Similarly, these additives enhance the structural properties of the bituminous layers, making roads last longer and perform better under pressure.

Key Concepts

-

Dense Bituminous Macadam (DBM): A layer that provides strength and resilience in flexible pavements.

-

Bituminous Concrete (BC): Designed to handle heavy traffic loads with enhanced durability.

-

Additives: Materials that improve the properties and performance of bituminous layers.

Examples & Applications

Using DBM in urban roads to handle heavy loads due to increased traffic.

Applying BC in highways to provide a durable surface capable of resisting deformation.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

For roads that bear their weight, DBM stands tall and straight.

Stories

Imagine a busy highway; DBM and BC are like two best friends working together to carry heavy loads while keeping the road smooth and safe.

Memory Tools

Remember DBM as 'Densely Built Macadam' and BC as 'Best Concrete' for high traffic.

Acronyms

Use 'R-P-N' for Additives

Rubber

Polymers

Nano-materials.

Flash Cards

Glossary

- Dense Bituminous Macadam (DBM)

A dense, well-graded layer used as a base in flexible pavements, providing strength and load distribution.

- Bituminous Concrete (BC)

A hybrid material that uses bitumen as a binding agent, designed for creating strong and durable pavement surfaces.

- Additives

Materials such as polymers, rubber, and nano-materials added to enhance the performance characteristics of bituminous layers.

Reference links

Supplementary resources to enhance your learning experience.