Equations

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Slenderness Parameter Introduction

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we will delve into the slenderness parameter, or ϕ, which relates to the buckling behavior of steel columns. Can anyone remind me what thickness versus length has to do with stability?

I think shorter and thicker members are usually more stable.

Exactly! The slenderness parameter helps us quantify that stability. Specifically, it integrates both the slenderness ratio and material properties, which is essential for inelastic buckling scenarios.

So, is this parameter better than just using the slenderness ratio?

Yes! The slenderness ratio alone can be misleading in some contexts. This parameter gives us a more accurate assessment of buckling risk.

To remember the relationship, think of the acronym 'PSM' for 'Parameter Slenderness Measure'.

That helps! What does K stand for again in the equations?

Good question! K refers to the effective length factor, which is determined by end conditions.

So to summarize, the slenderness parameter incorporates both the ratio and material properties, and is crucial for accurate stability analysis.

Understanding Critical Stress Equations

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now that we understand the slenderness parameter, let’s look at the equations for critical stress. Who can explain the difference between inelastic and elastic buckling?

Inelastic buckling happens before the material reaches its yield stress?

That's correct! For inelastic buckling, the equation is F_cr = 1 * F_y / ϕ^2 when ϕ is less than π^2.

What about the other equation?

For elastic buckling, when ϕ is greater than π^2, we use F_cr = F_y / ϕ^2. This indicates the material behaves elastically until it reaches the critical load.

What does tangent mean in this context?

Great question! It means at the transition between inelastic and elastic buckling, the two equations touch but do not cross each other. This point signifies a critical design consideration.

To wrap up, remember: 'Inelastic before elastic' as a mnemonic to recall that inelastic buckling is analyzed first.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section introduces the slenderness parameter and its importance in the analysis of steel columns under buckling. It differentiates between inelastic and elastic buckling by illustrating how the parameter affects the critical stress equations for concentrically straight members.

Detailed

Detailed Summary

Introduction

In this section, we explore critical equations from the AISC related to steel compression members, focusing on the analysis and design according to LRFD (Load and Resistance Factor Design).

Slenderness Parameter

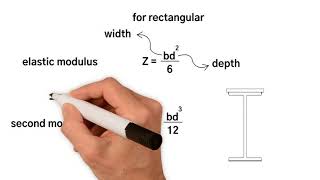

The slenderness parameter (ϕ), defined as:

ϕ^2 = F_y / F_Euler, using the expressions:

- ϕ^2 = KL / r_min

- ϕ = KL / r_min for F_y / [(2E)^2]

This parameter is crucial in distinguishing between inelastic and elastic buckling scenarios. It incorporates both slenderness ratio and material properties, making it a more suitable measure than slenderness ratio alone for the analysis of inelastic buckling.

Critical Stress Equations

The equations governing critical stress for elastically and inelastically buckled members are introduced:

-

For inelastic buckling (ϕ < π^2):

F_cr = 1 * F_y / ϕ^2

This scenario assumes gross yielding as a limiting case. -

For elastic buckling (ϕ > π^2):

F_cr = F_y / ϕ^2

In this situation, Euler’s equation prevails.

These two equations are tangent at the transition point, marking the shift from inelastic to elastic behavior.

Conclusion

The equations highlighted are significant for understanding the behavior and design considerations of concentrically straight steel members under axial loading.

Youtube Videos

Key Concepts

-

Slenderness Parameter (ϕ): A measure integrating slenderness ratio and material properties for assessing buckling risk.

-

Inelastic vs. Elastic Buckling: Inelastic buckling occurs prior to yield strength being reached, while elastic buckling happens under elastic conditions.

Examples & Applications

Example 1: Assessing a steel column with a length of 12 ft and radius of 1.5 in to determine its slenderness parameter and buckling method to be applied.

Example 2: Calculating F_cr for a column when F_y is 36 ksi and identifying which equations to use based on calculated slenderness parameter.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

A stiff steel beam that's quite tall, with the right shape, won't surely fall.

Stories

Imagine a tall building - its design considers both height and width for safety; too slender, it sways dangerously in the wind.

Memory Tools

PEB: P for Parameter, E for Elastic, B for Buckling - to remember the stage of critical load analysis.

Acronyms

SMART

Slenderness Measure Allows for Robust design and Transition in buckling scenarios.

Flash Cards

Glossary

- Slenderness Parameter (ϕ)

A parameter that incorporates slenderness ratio and material properties, crucial for analyzing buckling scenarios.

- Inelastic Buckling

Buckling that occurs before the material reaches its yield stress.

- Elastic Buckling

Buckling behavior that arises once a material reaches its elastic limit.

- F_y

Yield strength of the material.

- F_Euler

The critical stress defined by Euler’s formula addressing elastic buckling.

- K

Effective length factor that accounts for end conditions of columns.

Reference links

Supplementary resources to enhance your learning experience.