Analysis of Steam Turbines

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Steam Turbines

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Welcome, class! Today, we'll begin our exploration of steam turbines. Can anyone tell me what a steam turbine does?

Is it something that converts steam energy into mechanical work?

Exactly! Steam turbines convert thermal energy from high-pressure steam into mechanical work. This process is based on the principles of impulse and reaction. Let's dive into the classifications...

What's the difference between impulse and reaction turbines?

Great question! Impulse turbines fully expand steam in stationary nozzles, converting kinetic energy into work. In reaction turbines, steam expands across fixed and moving blades, resulting in pressure drop and energy extraction. Remember: impulse focuses on kinetic energy. We can use 'Impulse = Kinetic' to recall this!

Impulse vs Reaction Turbines

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s discuss impulse turbines first. Can anyone tell me how they convert energy into work?

Steam converts entirely to kinetic energy in the moving blades, right?

Correct! There’s no pressure drop across the blades. Now, what about reaction turbines?

They work with both fixed and moving blades, so there is a pressure drop, right?

Yes! that's right. The combination of pressure drop across both blade sets helps extract more energy. Remember to relate impulse with high-speed jets and reaction with partial expansion.

Compounding Methods

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

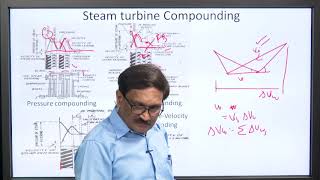

Now, let’s move on to compounding methods. Who can explain velocity compounding?

It's used to handle high-pressure drops without excessive blade speeds, right?

Exactly! Velocity compounding uses multiple moving blades with fixed blades in between to redirect steam. Remember the acronym 'CVD' for Compounding, Velocity, and Drop!

What about pressure compounding?

Good follow-up! Pressure compounding splits total pressure drop across several stages, making each stage like a separate impulse turbine for better efficiency. Excellent job!

Combined Compounding

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let's discuss combined pressure-velocity compounding. Why do we combine methods?

To design turbines that work with large pressure drops while keeping speeds moderate?

Correct! This approach provides versatility in turbine design while enhancing efficiency. Remember, flexibility in design is key for handling various operational conditions.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

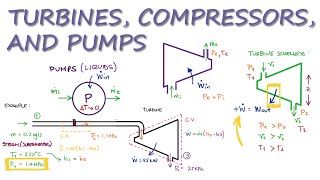

Steam turbines are classified into impulse and reaction types based on how steam is converted to work. Various compounding methods, including velocity and pressure compounding, optimize efficiency and control output.

Detailed

Analysis of Steam Turbines

Steam turbines are highly efficient rotary engines that transform thermal energy generated from high-pressure steam into mechanical work. This transformation hinges on the principles of impulse and reaction, leading to two primary classifications of turbines:

- Impulse Turbines: In these turbines, steam expands completely in stationary nozzles, generating high-velocity jets. There’s no pressure drop across the moving blades, focusing solely on converting kinetic energy into work.

- Reaction Turbines: Here, steam expands partially across both fixed and moving blades. A pressure drop occurs across both, leading to energy extraction via pressure reduction.

In the context of maximizing operational efficiency, several compounding processes are implemented:

- Velocity Compounding (Curtis Turbine): This method is used for high pressure drop scenarios to mitigate excessive blade speed by utilizing multiple sets of moving blades alternating with fixed blades to redirect steam.

- Pressure Compounding (Rateau Turbine): Here, total pressure loss is segmented into multiple stages, each incorporating a nozzle and rotor, promoting controlled drops and heightened efficiency.

- Combined Pressure-Velocity Compounding: This hybrid methodology facilitates flexible turbine designs ideal for large pressure drops with moderate speeds, ultimately improving efficiency, demonstrating the intricate design features prevalent in steam turbine technology.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Overview of Steam Turbines

Chapter 1 of 8

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Steam turbines are rotary engines that convert thermal energy of high-pressure steam into mechanical work.

Detailed Explanation

Steam turbines are machines designed to convert the energy stored in high-pressure steam into mechanical work, which can be utilized for various purposes such as generating electricity. The steam's thermal energy is transformed into mechanical energy through a process that involves moving blades within the turbine. This is crucial for many industrial applications, highlighting their efficiency in harnessing energy.

Examples & Analogies

You can think of a steam turbine like a windmill. Just as wind moves the blades of a windmill to produce mechanical energy that can turn a generator, steam pushes against the blades of a turbine to do the same.

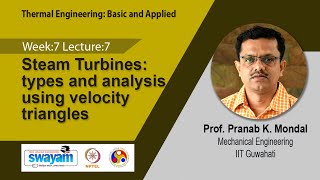

Types of Steam Turbines

Chapter 2 of 8

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Based on the principle of impulse and reaction, turbines are classified as:

○ Impulse turbines

○ Reaction turbines

Detailed Explanation

Steam turbines are primarily classified into two categories based on how they operate: impulse turbines and reaction turbines. Impulse turbines work by directing high-speed jets of steam onto blades, causing them to move. On the other hand, reaction turbines allow steam to expand while it passes through both fixed and moving blades, converting the pressure energy into mechanical energy. Each type has unique characteristics that make them suitable for different applications.

Examples & Analogies

Imagine a garden hose: when you cover part of the opening with your thumb, the water jets out forcefully (like in an impulse turbine). In contrast, if you only partially cover it, the water flows steadily and gradually loses pressure as it comes out (similar to a reaction turbine).

Impulse Turbines

Chapter 3 of 8

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Impulse Turbine

● Steam expands completely in stationary nozzles, resulting in high-velocity jets

● No pressure drop across moving blades; only kinetic energy is converted to work

Detailed Explanation

In an impulse turbine, steam releases its energy entirely in the nozzles before it hits the turbine blades. This means that the steam achieves a high velocity, which is then harnessed by the blades, causing them to turn. There is no pressure drop on the blades themselves; instead, the blades rely on the kinetic energy of the steam jets to perform work, making this a straightforward and efficient design for certain scenarios.

Examples & Analogies

You can visualize this like a water fountain where you have a nozzle shoot out water at high speed. The water strikes the paddles on a waterwheel (which resembles turbine blades), causing it to spin due to the force of the rushing water.

Reaction Turbines

Chapter 4 of 8

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Reaction Turbine

● Steam expands partially in both fixed and moving blades

● Pressure drop occurs across both sets of blades

Detailed Explanation

Unlike impulse turbines, reaction turbines allow steam to expand as it flows through both the fixed and moving blades. This interaction generates a drop in pressure as the steam passes through the stages. This continuous expansion and pressure drop effect are integral for extracting energy efficiently across multiple stages of the turbine, which enhances performance and can lead to better energy conversion.

Examples & Analogies

Think of it like a spiral slide at a playground. As kids slide down, they lose potential energy and gain speed while navigating both the curves and turns of the slide. Similarly, in reaction turbines, as steam navigates through the blades, it continuously converts thermal energy into mechanical speed.

Work Output of Impulse Turbines

Chapter 5 of 8

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Work output per stage (impulse):

W=m(Vw1+Vw2)u

Where:

● mm: mass flow rate

● Vw1,Vw2: whirl components of velocity

● u: blade speed

Detailed Explanation

The work output of an impulse turbine stage can be mathematically expressed. In this equation, 'm' represents the mass flow rate of the steam, and 'Vw1' and 'Vw2' signify the velocities of the steam as it interacts with the blades at two different points. The variable 'u' indicates the speed of the blades. This equation illustrates how the energy harnessed from the steam is calculated based on its mass flow and velocity components.

Examples & Analogies

This can be likened to filling a pitcher with water. The amount of water you pour (mass flow rate) and how fast you tilt the pitcher (blade speed) determine how much water comes out and at what speed, which is similar to how turbines capture and convert steam energy.

Velocity Compounding (Curtis Turbine)

Chapter 6 of 8

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Used when pressure drop is high and high-velocity jets would cause excessive blade speed

● Achieved by using multiple sets of moving blades with fixed blades in between to redirect steam

Features:

● Single pressure drop in nozzle

● Multiple velocity drops in rotor stages

● Reduces blade speed requirements

Disadvantages:

● Mechanical complexity

● More energy losses due to repeated blade interactions

Detailed Explanation

Velocity compounding, such as in Curtis turbines, is employed to manage high-pressure drops and mitigate the risk of overly high speeds in turbine blades. This design utilizes multiple stages of moving and fixed blades that collectively redirect steam, allowing for a single pressure drop while managing speed effectively. However, this system also brings mechanical complexity and potential energy losses as the steam repeatedly interacts with different blade arrangements.

Examples & Analogies

Imagine trying to pour a cold drink into a small glass while managing a busy table of drinks. Instead of pouring too fast and spilling (like excess blade speed), you strategically alternate pouring while swapping glasses (like changing the direction of steam in turbine stages) to maintain control and prevent messiness.

Pressure Compounding (Rateau Turbine)

Chapter 7 of 8

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Total pressure drop is divided into multiple stages

● Each stage consists of a nozzle (for pressure drop) and a rotor (for energy extraction)

Features:

● Controlled pressure drop in multiple stages

● Each stage acts like a separate impulse turbine

● Lower velocity and better efficiency

Detailed Explanation

Pressure compounding methods, such as those used in Rateau turbines, divide the overall pressure drop into several discrete stages. Each stage comprises a nozzle for managing pressure and a rotor for extracting energy, which means each section functions similarly to an impulse turbine. This staged approach tends to lower the velocity of the steam while improving overall efficiency, emphasizing an organized approach to energy extraction.

Examples & Analogies

Picture a staircase made up of several steps. Rather than trying to jump a tall staircase in one leap (high pressure drop), it’s much more manageable and efficient to ascend one step at a time. Each step allows for a controlled ascent, which mirrors how energy is extracted progressively in staged turbines.

Combined Pressure-Velocity Compounding

Chapter 8 of 8

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Combination of both pressure and velocity compounding

● Allows flexible turbine design for large pressure drops with moderate speeds and high efficiency

Detailed Explanation

Combined pressure-velocity compounding takes advantage of both previous methods, allowing for better adaptability in turbine design. This hybrid approach is especially beneficial for scenarios involving large pressure drops, enabling turbines to maintain moderate speeds while maximizing efficiency. It highlights the ability to create more versatile and efficient turbine systems that cater to varying operational needs.

Examples & Analogies

Think of it as a hybrid vehicle that can switch between different modes of energy efficiency, like using both electric power and gasoline to optimize performance across varying terrains. Similarly, combined compounding allows turbines to adjust according to pressure and velocity needs for optimal energy output.

Key Concepts

-

Steam Conversion: The transformation of thermal energy from steam into mechanical energy.

-

Impulse and Reaction: The two classifications of turbines based on steam expansion.

-

Velocity and Pressure Compounding: Methods to optimize turbine performance based on specific operational needs.

Examples & Applications

In an impulse turbine, steam expands completely in the nozzle, generating high-speed jets crucial for the turbine's operation.

A reaction turbine uses both fixed and rotating blades; steam pressure decreases across these blades, enhancing energy extraction.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Steam flows high and twists around, impulse jets are swiftly found.

Stories

Imagine a river splitting into two: One side rushes down with full force (impulse), while the other cascades through rocks, slowly gaining strength (reaction).

Memory Tools

I>V>P - Impulse for Velocity before Pressure for Compounding.

Acronyms

SCR - Steam Conversion Rate

Remembers the flow from steam to mechanical work.

Flash Cards

Glossary

- Steam Turbine

A rotary engine that converts thermal energy from high-pressure steam into mechanical work.

- Impulse Turbine

A turbine where steam expands fully in stationary nozzles, creating high-velocity jets.

- Reaction Turbine

A turbine that partially expands steam across both fixed and moving blades with a pressure drop.

- Velocity Compounding

A method of using multiple sets of blades to control speed in turbines with high-pressure drops.

- Pressure Compounding

The division of total pressure drop across multiple turbine stages to improve efficiency.

- Combined Compounding

A method that integrates both velocity and pressure compounding to enhance turbine design and performance.

Reference links

Supplementary resources to enhance your learning experience.