Basic Components of a Control System

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Understanding the Input

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's begin our discussion on control systems by talking about the first crucial component, the input. Can anyone tell me what input means in the context of a control system?

Isn't the input what we want to achieve, like the temperature we set on a thermostat?

Exactly! The input represents the desired condition or setpoint. It's essential because it guides what the control system is trying to achieve.

So, if I set my room temperature to 22 degrees, that becomes the input for the heating system?

Right! Good example! Now, why is establishing the right input critical for the performance of the control system?

If the input is set incorrectly, the system might work hard to achieve the wrong target!

Spot on! If the input is incorrect, the entire system's performance can be compromised. Remember this: without a clear target, you can't effectively implement control. Great job, everyone!

Exploring the Role of the Controller

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's move on to the second component of our control system: the controller. Who can explain what a controller does?

I think the controller compares the output to the input, right?

That's correct! The controller generates a control signal to correct any discrepancies. Can you describe how this might work in a real system?

In a heating system, if the current temperature is 20 degrees but the desired temperature is 22 degrees, the controller will send a signal to the heater.

Great explanation! And often the controller follows a particular strategy, like the Proportional-Integral-Derivative or PID controller. Does anyone remember what PID stands for?

Proportional, Integral, and Derivative!

Exactly! Each of these components plays a role in how the controller manages discrepancies. Can someone explain what each of those terms means in simple words?

Proportional reacts to the current error, Integral considers past errors, and Derivative anticipates future errors.

Well explained! So remember, an effective controller dynamically adjusts output based on a comparison against inputs to maintain performance.

Understanding Feedback

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s delve into the feedback component of a control system. Who can define what feedback is?

Feedback is the information sent back to the controller to compare the actual output with the desired setpoint.

Exactly! Feedback is crucial for the system to adjust its performance effectively. How does that look in practical situations?

In a thermostat, it checks the room temperature and informs the system whether to turn the heating on or off.

Exactly! And what type of feedback system do we use most often?

We usually use negative feedback, right? It helps stabilize the system.

Yes! Negative feedback counteracts deviations from the desired output, enhancing system stability. Fantastic job!

The Actuator and Output

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

We have discussed input, controllers, and feedback. Now, let’s explore actuators and output. What role do actuators play in the control system?

Actuators implement the control signal generated by the controller, right? Like motors or valves.

Correct! They are the physical devices that carry out the action. Can someone give me an example of an actuator in another context?

An electric motor in a conveyor belt system!

Excellent! Now, what about the output? What does output refer to in our control system?

Output is the actual result of the controller’s actions, like the current temperature of the room.

Correct! The output is what we measure to ensure it meets our input goals. Each component—input, controller, feedback, actuator, and output—works together seamlessly in a control system to achieve the desired performance.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

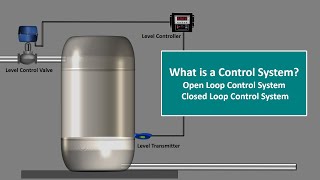

Control systems consist of six primary components: input, controller, process/plant, feedback, actuator, and output. These components collaborate to ensure that a system can achieve a desired state and adjust accordingly to maintain performance amidst variable conditions.

Detailed

Detailed Summary

Control systems are essential for managing dynamic processes in engineering. A basic control system generally comprises six core components:

- Input - The desired condition or setpoint the system aims to achieve (e.g., target temperature).

- Controller - Compares the output with the input and generates a control signal to correct discrepancies, often using a Proportional-Integral-Derivative (PID) strategy.

- Process/Plant - The system being controlled (e.g., an electric motor), which processes the controller's commands into a physical output.

- Feedback - Measures the actual output and compares it with the desired output, providing information back to the controller for error minimization.

- Actuator - Implements the control action decided by the controller, such as motors or valves.

- Output - Reflects the actual response of the system, which is monitored against the desired setpoint.

Understanding these components is crucial for designing control systems that maintain desired outputs in varying conditions.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Input

Chapter 1 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Input: The desired condition or setpoint that the system aims to achieve. For example, in a temperature control system, this could be the desired room temperature.

Detailed Explanation

The input in a control system is the target condition that the system is designed to achieve. This is also referred to as the setpoint. It represents the desired outcome that the system should reach. For example, in a temperature control system, the input may be set to a specific temperature, such as 22°C, indicating that this is the comfort level expected in a room.

Examples & Analogies

Think of a thermostat in your home. When you set the thermostat to 22°C, you are providing the system with the input it needs to maintain that temperature. If the room gets too cold or too hot, the thermostat's control system will kick in to bring the temperature back to 22°C.

Controller

Chapter 2 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

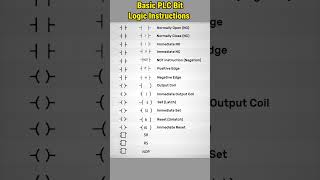

- Controller: The controller compares the output with the input (desired value) and generates a control signal to reduce any discrepancy. Common controllers include Proportional-Integral-Derivative (PID) controllers.

Detailed Explanation

The controller is a crucial component of a control system that receives the input and output information. It continuously monitors the difference or error between the desired input (setpoint) and the actual output. When it detects a discrepancy, it generates a control signal to correct the system's output and minimize that error. PID controllers are the most commonly used types, comprising three terms: proportional, integral, and derivative, which work together to enhance system stability and performance.

Examples & Analogies

Consider a student aiming to achieve a specific grade in a course. The teacher represents the controller, who regularly checks the student's assignments (output) against the desired grade (input). If the student is falling behind, the teacher can offer additional help or resources to improve their performance and get closer to the desired grade.

Process/Plant

Chapter 3 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Process/Plant: This is the system being controlled, such as a motor, temperature system, or industrial machine. The process converts the controller’s command into a physical output.

Detailed Explanation

The process, also referred to as the plant, is the physical system or component that the control system aims to regulate. This could be anything from a heating system to an industrial motor. The role of the process is to take the control signals generated by the controller and transform them into a tangible output, such as increasing the temperature of a room or rotating the shaft of a motor.

Examples & Analogies

Imagine a car engine as the process in a control system. The engine receives commands (control signals) from the car's computer (controller) to adjust the fuel flow based on the desired speed. The engine then converts those signals into physical motion (the car moving forward) based on its design and mechanics.

Feedback

Chapter 4 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Feedback: This component measures the actual output and compares it with the desired output. The feedback is sent back to the controller for adjustments to minimize errors.

Detailed Explanation

Feedback is an essential part of a control system as it provides information about the current state of the output. It measures how close the actual output is to the desired output and sends this information back to the controller. By comparing the actual output with the desired setpoint, the controller can make real-time adjustments to keep the system on track and minimize any errors or deviations.

Examples & Analogies

Think of a driver maintaining a specific speed on a highway. The car's speedometer acts as feedback, showing the driver the actual speed. If the driver is going too fast or slow compared to the desired speed limit, they will adjust the accelerator or brake to correct their speed, thereby using feedback to maintain the appropriate pace.

Actuator

Chapter 5 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Actuator: A device that implements the control action generated by the controller. For example, an electric motor or a valve could act as an actuator.

Detailed Explanation

An actuator is the component of a control system responsible for executing the control actions determined by the controller. It translates the control signals into physical actions that apply to the process or plant. This could be turning a valve to increase the flow of water or starting an electric motor to drive machinery. The actuator essentially bridges the gap between the control logic and the physical effects in the system.

Examples & Analogies

Consider a robotic arm used in manufacturing. The controller sends signals to the actuators in the arm, instructing it to move in specific ways. When the controller instructs the robotic arm to pick up an object, the actuators respond by moving the arm's joints accordingly, completing the action.

Output

Chapter 6 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Output: The actual result or the response of the system that is measured and compared with the desired setpoint.

Detailed Explanation

The output is the result produced by the control system based on the command received from the controller and the actions taken by the actuator. It represents the actual state of the process and is crucial for determining how well the system is performing. The output is continuously monitored to ensure it meets the desired setpoint, allowing the system to maintain its effectiveness.

Examples & Analogies

If we return to the heating system example, the output would be the actual temperature of the room. If the system succeeds in raising the temperature to 22°C (the desired input), then the output meets the setpoint, confirming that the control system is working effectively.

Key Concepts

-

Input: The target that the control system aims to achieve.

-

Controller: The system component that generates control signals based on discrepancies.

-

Process/Plant: The actual system being managed.

-

Feedback: Information processed back to control for adjustments.

-

Actuator: Devices that implement control decisions.

-

Output: The result measured against setpoints.

Examples & Applications

In a heating system, the desired temperature setting is the input, while the actual temperature is the output, and the thermostat acts as the controller.

In an automated assembly line, actuators move elements based on controller's commands, adjusting production processes dynamically.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

An input is set, to get what we want, and feedback keeps checks to ensure we won’t daunt.

Stories

Imagine a chef following a recipe (input) while constantly tasting the dish (feedback) to adjust the flavors (controller), adding spices or salt (actuator) to achieve the desired taste (output).

Memory Tools

I-C-F-A-O: Input, Controller, Feedback, Actuator, Output are the key components of control systems.

Acronyms

PICFA

Proportional

Integral

Controller

Feedback

Actuator - these are vital players in a control system.

Flash Cards

Glossary

- Input

The desired condition or setpoint that a control system aims to achieve.

- Controller

The component that compares the output with the input and generates a control signal.

- Process/Plant

The actual system being controlled that converts commands into physical output.

- Feedback

The information sent back to the controller to compare actual output with desired output.

- Actuator

A device that carries out the control action generated by the controller.

- Output

The actual result of the system measured against the desired setpoint.

Reference links

Supplementary resources to enhance your learning experience.