Characteristics of the compactor

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Mass and Size of Compactors

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Good morning, everyone! Today, we will start by discussing one of the first important characteristics of compactors, which is their mass and size. Can anyone tell me why the mass of a compactor might be important?

I think heavier compactors are more effective for dense soils.

Exactly! A higher mass leads to greater contact pressure on the soil, improving compaction. What about size?

Larger compactors can cover more area, right?

Good point! Size is crucial for reaching all areas needed for compaction. Now let’s remember this with the acronym 'MAP' which stands for Mass and Area Pressure.

So, MAP can help us remember the importance of mass and size together?

Yes! Great job, everyone. To summarize today, compactors need to have appropriate mass and size to effectively compact various types of soils.

Operating Frequency and Frequency Range

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s discuss operating frequency. Can anyone tell me what it means when we talk about a roller operating at different frequencies?

Does that relate to how quickly the vibrations occur?

Exactly right! Higher frequencies can make for more effective compaction by helping to displace air and water within the soil. Why do you think frequency range is also important?

It might be because different soils require different frequencies for optimal compaction?

Spot on! We must match the frequency to the type of soil. Remember the rhyme: ‘Big rolls have wavy rhythms to make the soil flat and firm’ to think of this concept.

I like that rhyme! It helps me remember!

Let’s wrap this up: operating frequency and its range are crucial for effectively compacting soils by enhancing vibration efficiency.

Soil Characteristics

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let's look at soil characteristics. What are the three main properties of soil that we should consider for compaction?

Initial density, grain size and shape, and water content?

Exactly! The initial density will determine how much more compacted the soil can become. What about grain size?

Finer grains compact easier than coarse grains.

Right! But we have to be careful because if there is too much water, we could lose compaction effectiveness. Remember, WAD - for Water, Aggregate, Density!

That's helpful! WAD helps us recall the critical factors of soil.

Great! In summary, understanding these soil characteristics is essential for successful compaction.

Construction Procedures

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s talk about construction procedures. Can anyone tell me what the number of passes means?

How many times the roller goes over the same spot, right?

Exactly! The number of passes can determine how compacted the soil will be. What else can we modify?

Lift thickness! Thinner lifts might compact better!

Yes, thinner layers often lead to better compaction! Let's remember LARP - Lift thickness, And Relative passes.

LARP is fun and easy to remember!

Fantastic! To summarize, modifying the number of passes and lift thickness are key components of effective soil compaction.

Degree of Compaction

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let’s talk about the degree of compaction. What do we mean by relative compaction?

Isn't it about how compacted the soil is compared to its optimum density?

Correct! Measuring the degree of compaction helps us assess compaction success. Does anyone know how this is usually done?

Using a compaction test?

Yes! Tests such as the Proctor test help us determine this. To remember, think CAP - Compaction Assessment Protocol.

I will use CAP to recall the assessment process!

Excellent! In summary, the degree of compaction reveals how effective our compaction efforts have been.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

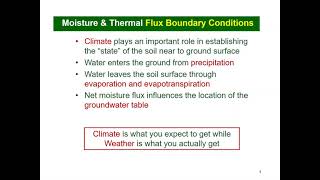

The section highlights the essential characteristics of compactors, including mass and operating frequency, and details the properties of soil that influence compaction, such as density, grain size, and water content. It also examines construction procedures like the number of roller passes and lift thickness, concluding with the concept of degree of compaction.

Detailed

Characteristics of the Compactor

This section discusses the important factors that affect the performance of compactors used in construction. Three key characteristics of the compactor are emphasized: mass and size, which influence the compactor's effectiveness; along with operating frequency and frequency range, which play a critical role in determining how well the equipment can compact different types of soil.

Alongside the compactor characteristics, the properties of soil such as initial density, grain size and shape, and water content are discussed as significant factors affecting the compaction process.

The construction procedures cover aspects such as the number of passes the roller must make, lift thickness, the frequency of operation for vibrators, and towing speed, highlighting the meticulous steps needed for effective compaction. Finally, it introduces the concept of relative compaction, providing insight into measuring the effectiveness of the compaction process.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Mass and Size of the Compactor

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Mass, size

Detailed Explanation

The mass and size of a compactor significantly influence its performance. A heavier compactor exerts a greater force on the ground, leading to more efficient soil compaction. Size matters because it determines the area that can be covered and the depth of compaction. Thus, for different construction projects, selecting the right mass and size of the compactor ensures that the ground is compacted evenly and to the required specifications.

Examples & Analogies

Think of a compactor like a chef making dough. If the chef has a heavy rolling pin, they can press down harder and flatten the dough more quickly and evenly than if they had a lighter one. Similarly, a heavy compactor can compress soil more efficiently than a lightweight machine.

Operating Frequency and Frequency Range

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Operating frequency and frequency range

Detailed Explanation

The operating frequency refers to how often the compactor vibrates while working. Different frequencies cause variations in how effective the compactor is on various soil types. A lower frequency might be suitable for heavier, denser soils, while higher frequencies are often better for lighter soils. Understanding the correct frequency range helps achieve optimal compaction without damaging the soil structure.

Examples & Analogies

Imagine trying to vibrate a trampoline with people jumping on it. If too many people jump close together (high frequency), it may break. But with the right timing (the right frequency), everyone can jump and the trampoline bounces perfectly. In a similar way, the compactor needs the right operating frequency to compact soil effectively.

Key Concepts

-

Mass: Influences the effectiveness of compaction.

-

Operating Frequency: Determines the efficiency of vibration during compaction.

-

Initial Density: Affects how much the soil can be compacted.

-

Grain Size and Shape: Determines ease of compaction based on soil type.

-

Water Content: Must be optimized for effective compaction.

-

Lift Thickness: Thinner layers generally lead to better compaction.

-

Degree of Compaction: Measured to evaluate compaction effectiveness.

Examples & Applications

A heavy roller is more effective on clay soil than on sandy soil.

Increasing water content can make soil easier to compact, but too much water can lead to poor compaction.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Rollers so heavy, and vibrating quick, compact the soil, they do the trick.

Stories

A team of construction workers found that when they rolled out their heavy compactor on a rainy day, it made the mud easier to flatten but too much mud made their job harder. They learned just the right amount of water made for a perfect compacted ground.

Memory Tools

WAD - Water, Aggregate, Density helps remember the properties of soil.

Acronyms

MAP - Mass and Area Pressure summarizes the importance of mass and size in compactors.

Flash Cards

Glossary

- Mass

The weight of the compactor, influencing its compaction ability.

- Operating Frequency

The rate at which vibrations occur in the compactor.

- Initial Density

The density of the soil before compaction.

- Grain Size and Shape

Physical characteristics of soil particles affecting compaction.

- Water Content

The amount of water present in the soil during compaction.

- Lift Thickness

The depth of the layer of soil being compacted.

- Degree of Compaction

A measure of how well the soil has been compacted relative to its maximum density.

Reference links

Supplementary resources to enhance your learning experience.