Frequency of Operation Vibrator

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Impact of Vibrator Frequency

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we will discuss how the frequency of operation for vibrators affects our compaction efforts. Can anyone share why frequency might be important?

I think it affects how well the soil is compacted, right?

Exactly! The right frequency can enhance the effectiveness of compaction. A useful way to remember this is 'Vibrate to Complicate Not Overcomplicate.' Let's explore why factors like soil density matter.

What specific soil characteristics should we keep in mind?

Great question! We need to consider the initial density, grain size, and water content of the soil.

Does that mean different soils need different frequencies?

Absolutely! Each soil type has a frequency sweet spot that maximizes compaction. Let’s summarize: the correct frequency improves compaction efficiency.

Optimization of Compaction Procedures

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's discuss how we can optimize our compaction processes. Which factors do you think we should optimize?

The number of passes of the roller and lift thickness could be important.

Correct! The number of passes and lift thickness directly influences how the frequency should be applied.

How does towing speed fit into this?

Good point, towing speed impacts how uniformly the vibration is distributed. A slower speed may allow for more effective compaction.

So it’s all interconnected?

Yes! We need to consider the entire system for effective compaction. Remember: 'Focusing on the frequency harmonizes our compaction.' Let's wrap up with our key takeaways.

Challenges with Soil Types

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's address that different soil types react differently to vibration frequencies. What happens with clay vs. sandy soil?

Clay might need a lower frequency because it's denser?

Exactly! Clay tends to respond best to lower frequencies, while sandy soils might do better with higher frequencies.

What impact does water content have on this?

Water content affects cohesion in soil, which can alter the optimal frequency. High water content can prevent adequate compaction.

That’s interesting! So choosing the right frequency is about knowing your soil well?

Exactly! Soil knowledge is key for effective compaction. Let’s finish with this thought: 'Know your soil, know your frequency.'

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The frequency of operation for vibrators is crucial in construction procedures as it affects the degree of compaction achieved in different soil types. Understanding how factors such as water content, grain size, and initial density influence this relationship is essential in optimizing compaction efforts.

Detailed

In the construction industry, the frequency of operation of vibrators plays a pivotal role in achieving effective soil compaction. This section outlines various characteristics that impact compaction, including the mass and size of the compactor, the initial density and grain properties of the soil, and the moisture content. The operating frequency must be aligned with these soil characteristics to ensure optimal compaction results. Factors such as the number of passes of the roller, lift thickness, towing speed, and especially the frequency of vibration used during compaction are discussed. Understanding these dynamics is crucial for ensuring adequate relative compaction, ultimately contributing to the integrity and longevity of any construction project.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Understanding Vibrator Frequency

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

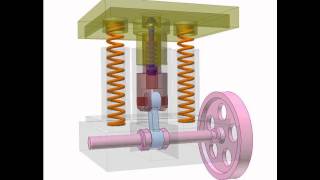

The frequency of operation of a vibrator in compaction is crucial to achieving desired soil properties and grain density.

Detailed Explanation

The frequency of operation of a vibrator is a key factor in soil compaction. When a vibrator operates, it generates vibrations that help displace air and water, allowing soil particles to rearrange themselves into a denser configuration. Higher frequencies can lead to more rapid movement of particles, while lower frequencies might be more effective for specific types of soil.

Examples & Analogies

Imagine a dance floor where people are shuffling around. If the music is very fast (high frequency), everyone moves quickly and might bump into each other, increasing interaction (like particles in soil). However, if the music is slow (low frequency), people move more methodically in their spaces, allowing them to find a comfortable position (like settling soil particles).

Impacts of Frequency on Soil Compaction

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The choice of frequency will affect the depth and effectiveness of compaction, making it necessary to select appropriate setting based on soil characteristics.

Detailed Explanation

Different soil types react differently to vibrational frequencies. For instance, granular soils, such as sand, may compact more efficiently at higher frequencies, facilitating faster drainage of water. On the other hand, cohesive soils, like clays, may require lower frequencies for effective compaction, allowing time for moisture to escape without disrupting the soil structure.

Examples & Analogies

Think of cooking two different types of food. Cooking pasta rapidly in boiling water (high frequency) works well because it doesn’t need time to absorb moisture. But cooking rice, which needs gradual absorption (lower frequency), might produce better results if the heat is more controlled and steady.

Frequency Adjustment during Operation

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Operators may need to adjust the frequency during the compaction process based on feedback from the construction site.

Detailed Explanation

It’s essential for operators to be attentive to the compaction process and make frequency adjustments as needed. If the soil appears to be over-compacted, the frequency can be reduced, while an increase may be necessary if the desired compaction level is not achieved. Continuous monitoring of the vibratory compactor’s performance allows for real-time adjustments, optimizing the quality of the final compaction.

Examples & Analogies

Consider a musician tuning their instrument during a performance. The musician continuously adjusts their playing to match the acoustics of the venue or the sound of the ensemble. Similarly, a compaction operator tunes the frequency settings to achieve the best soil compaction results on-site.

Key Concepts

-

Operating Frequency: The frequency at which the vibrator operates, crucial for optimizing compaction.

-

Soil Characteristics: Initial density, grain size, and water content impact compaction effectiveness.

-

Degree of Compaction: Measure of how well the soil has been compacted relative to maximum density.

Examples & Applications

If a vibratory compactor is used on sandy soil, it might require a higher frequency for effective compaction.

In contrast, a clay soil might require lower frequencies for optimal density because of its cohesive nature.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

When soil is packed and feels just right, the frequency's low, it feels so light.

Stories

Imagine a construction worker who must decide between a slow and steady compaction of clay versus a speedy compaction of sand. The lesson he learns is that every soil has its unique personality, needing the right frequency to behave properly.

Memory Tools

F_S_G_C: Focus on Soil Grain and Compaction - Remember to check Frequency, Soil type, Grain size, and Cohesion.

Acronyms

C-FIX

Compaction Frequencies Improve X-factor (degree of compaction) across soil.

Flash Cards

Glossary

- Initial Density

The measure of how compact the soil is before compaction efforts are applied.

- Grain Size

The size of individual particles in the soil, which can impact compaction effectiveness.

- Water Content

The amount of water present in the soil, affecting its compaction properties.

- Operating Frequency

The frequency at which the vibrator operates, crucial for optimizing compaction in soil.

- Degree of Compaction

The extent to which soil has been compacted relative to its maximum density.

Reference links

Supplementary resources to enhance your learning experience.