Introduction to Torsion

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Fundamentals of Torsion

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

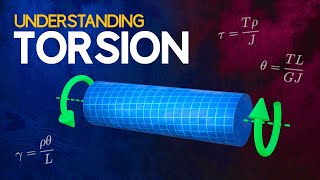

Today we'll explore torsion — the twisting of a shaft when subjected to torque. This twisting can lead to shear stress in the material, which is critical for understanding how structures behave under load.

Does that mean torsion only affects shafts?

Great question! While it's most relevant for shafts, any structure experiencing twisting can undergo torsion. Remember, Torsion leads to shear stress and deformation — think 'TSD' as a mnemonic.

What does the T in TSD stand for?

T is for Torsion. The D is for Deformation. This way, you can recall that torsion affects both shear stress and the way materials twist!

Calculating Torsional Shear Stress

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's dive into how we can calculate torsional shear stress in circular shafts. The formula τ = T*r/J applies here. Can anyone tell me what each component represents?

τ is shear stress, right? And T is torque?

Exactly! And what about r and J?

r is the radial distance from the center of the shaft, and J is the polar moment of inertia!

Perfect. And when calculating τ for a solid shaft, we use J = (π*d^4)/32. Don't forget this formula; it's crucial!

Angle of Twist

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next is the angle of twist, which is calculated using the formula θ = (T*L)/(G*J). What do all these variables tell us?

T is torque, L is the length of the shaft, G is the shear modulus, and J is again the polar moment of inertia.

Correct! And this equation reveals how long a shaft twists under a given torque. Can anyone summarize its significance?

It helps us understand how much a shaft will deform, which is crucial for designing mechanical systems.

Shaft Behavior Under Various Conditions

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Consider a shaft fixed at both ends. What must hold true for it to remain fixed when torque is applied?

The net angular displacement at the fixed ends should be zero.

Exactly! This calls for understanding internal torques. Can any of you think of how we can find those?

We can use equilibrium and deformation compatibility techniques!

Right on! These principles ensure our designs are stable under load.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section explains torsion, focusing on the behavior of circular shafts when subjected to torque, the calculation of shear stress and angle of twist, and various behaviors of shafts including those fixed at both ends and helical springs. Key formulas for shear stress and deflection are provided to understand the underlying mechanics.

Detailed

Introduction to Torsion

Torsion is the twisting of a structural member, typically a shaft, when it faces external torque, leading to shear stress and an angular deformation referred to as twist. This phenomenon predominantly applies to circular shafts, both solid and hollow, that are integral to mechanical systems, such as shafts, axles, and helical springs.

Key Points:

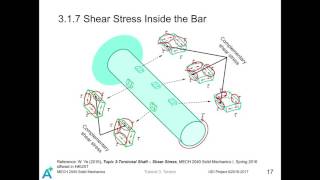

- Torsional Shear Stress: For a circular shaft under torque (T), shear stress (τ) at a radial distance (r) can be computed using the equation: τ = T*r/J, where J is the polar moment of inertia. For solid and hollow shafts, J varies based on their geometry.

- Angle of Twist and Torsional Deformation: The angle of twist (θ) is related to length (L), shear modulus (G), and J, expressed through θ = (TL)/(GJ). This enables assessment of twist per unit length and overall angular displacement based on the torque applied.

- Stepped Shafts: For shafts with multiple segments, total twist is derived from individual twists in these segments, necessitating the application of boundary conditions to find internal torque.

- Shafts Fixed at Both Ends: If both ends are fixed, the deformation compatibility must ensure no net angular displacement at the ends, using equilibrium and deformation principles to calculate internal torque.

- Helical Springs: These springs behave as torsional elements under load, with relevant formulas for shear stress and deflection derived from axial loads. Helical springs are essential in applications requiring energy absorption and storage.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Definition of Torsion

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Torsion refers to the twisting of a structural member (usually a shaft) when subjected to an external torque. The result is shear stress distributed over the cross-section and an angular deformation known as twist.

Detailed Explanation

Torsion is a mechanical phenomenon that occurs when a shaft or similar structural member is twisted due to an applied force called torque. When this happens, the material experiences shear stress, which means that different parts of the material slide past each other. This twist also leads to a change in the shaft's angle, called the angle of twist.

Examples & Analogies

Think of a rubber band. If you twist it, the band experiences stress that causes it to change shape. Similarly, when a metal shaft is twisted under force, it experiences torsion which affects its integrity and performance.

Application of Torsion

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Applicable primarily to circular shafts — both solid and hollow — used in mechanical systems like shafts, axles, and helical springs.

Detailed Explanation

Torsion is most relevant in circular shafts, whether solid or hollow. These shafts are components in various mechanical systems, such as car axles, where they transfer power, or in helical springs, where they absorb energy. Understanding how torsion acts on these shafts is critical for engineers to ensure that they can withstand the forces applied without failing.

Examples & Analogies

Imagine the axle of a bicycle. As you pedal, torque is applied to the axle, causing it to twist. If the axle is too weak to handle this torsion, it might break, leading to a malfunction. Thus, proper design and material selection are essential.

Key Concepts

-

Torsion: The twisting effect due to applied torque on a member.

-

Shear Stress: The force components acting parallel to a material's cross-section.

-

Angle of Twist: The angle by which a member twists under torque, calculated using θ = (TL)/(GJ).

-

Polar Moment of Inertia: A property that measures a shaft's resistance to twisting.

-

Helical Springs: Springs that act under axial load and are modeled as torsional elements.

Examples & Applications

A solid circular shaft with diameter 50 mm subjected to a torque of 100 Nm experiences specific shear stress and twist, calculated using the respective formulas.

A helical spring has a mean coil diameter of 10 cm and a wire diameter of 4 mm under an axial load of 200 N, which behaves according to torsional mechanics.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Twist and turn, oh shaft so strong, Under torque's load, you can't go wrong.

Stories

Once upon a time, a brave shaft stood firm against intense torque. With each twist, it learned about shear stress, discovering how it could handle loads and keep machines working smoothly.

Memory Tools

Use 'TSD' to remember Torsion, Shear Stress, and Deformation.

Acronyms

GJLT

Shear modulus (G)

Polar moment of inertia (J)

Length (L)

Torque (T) for angle of twist.

Flash Cards

Glossary

- Torsion

The twisting of a structural member when subjected to external torque.

- Shear Stress

The stress component parallel to a given surface, resulting from applied forces.

- Angle of Twist

The angular displacement of a shaft due to torsional loading.

- Polar Moment of Inertia

A measure of an object's resistance to torsional deformation, dependent on its geometry.

- Helical Spring

A spring made of a wire coiled in a helix that can store and release energy.

Reference links

Supplementary resources to enhance your learning experience.