Robotic Tunnel Boring Machines (TBMs)

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Robotic TBMs

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we’re discussing Robotic Tunnel Boring Machines, often called TBMs. Can anyone tell me what a TBM does?

Is it used for making tunnels?

Exactly! TBMs are used to construct tunnels in large infrastructure projects. They help in developing systems like metro rail and underground highways.

How do they operate differently from regular tunnel construction methods?

TBMs are automated, which means they operate with minimal human intervention. This allows for greater safety and efficiency. Think of them as robotic workers that can navigate underground layers systematically.

So they can work continuously?

Yes, that's right! They can operate for longer periods, which speeds up the construction process significantly.

To help remember this, think of the acronym 'TUNNELS' - TBMs Use Navigation for New Engineering in Large Spaces. Great way to recall their function!

That's helpful!

Excellent! Let's summarize today’s key points: TBMs create tunnels, they reduce labor needs, and they can operate continuously under various ground conditions.

Benefits of Robotic TBMs

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now that we understand what TBMs are, let’s discuss their benefits. Can anyone suggest why we might prefer TBMs over traditional methods?

They are safer?

Yes, safety is a major advantage. By reducing how much workers need to be in potentially hazardous areas, TBMs help prevent accidents.

What about efficiency?

Absolutely! Efficiency improves due to the continuous operation of TBMs. They can dig and install the tunnel lining simultaneously, reducing the overall project time.

Do they help in managing underground water too?

Great question! Yes, TBMs are designed to handle various geological conditions, including water. This capability is vital in urban areas where managing groundwater is important.

Let’s create a mnemonic to help remember these benefits: 'SPEED' for Safety, Precision, Efficiency, Effectiveness, and Durability!

That's easy to remember!

Excellent job! In summary, TBMs enhance safety, efficiency, and effectiveness in tunnel construction.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Robotic Tunnel Boring Machines (TBMs) play a crucial role in modern civil engineering for large infrastructure projects such as metro rail and underground highways. They utilize advanced robotics and automation to navigate through various underground layers while simultaneously constructing the tunnel's structural segments, showcasing a significant leap in construction efficiency and precision.

Detailed

Robotic Tunnel Boring Machines (TBMs)

Overview

Robotic Tunnel Boring Machines (TBMs) are sophisticated robotic systems designed for the construction of tunnels in large infrastructure projects. Unlike conventional methods which may require extensive manual labor and are often error-prone, robotic TBMs enhance both safety and efficiency in tunneling operations.

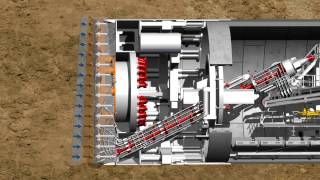

Functionality and Operation

These machines operate through a process that allows them to navigate through complex underground geology, including soil, rock, and water. While tunneling, TBMs simultaneously install tunnel liners which provide structural support. The automation involved with TBMs significantly reduces human intervention, resulting in safer working conditions and enhanced accuracy.

Significance in Civil Engineering

The integration of TBMs into civil engineering projects facilitates the completion of urgent infrastructure requirements such as metro systems and highways. They manage to operate continuously over long periods, which accelerates project timelines. In densely populated areas where surface disruption is minimized, TBMs offer a highly effective solution for developing underground infrastructure, thereby reshaping urban landscapes.

In summary, robotic TBMs represent a transformative step in tunneling technology that merges engineering with robotics, delivering precision and improved safety in complex construction environments.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to Robotic TBMs

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

In large infrastructure projects like metro rail and underground highways, robotic TBMs navigate underground layers while simultaneously laying tunnel segments.

Detailed Explanation

Robotic Tunnel Boring Machines (TBMs) are highly advanced machinery used in significant construction projects, particularly those that require tunneling beneath the earth's surface. These machines are capable of digging through various types of soil and rock while simultaneously installing tunnel segments as they move forward. This innovative approach not only speeds up the construction process but also enhances safety by minimizing the risks often associated with traditional tunneling methods.

Examples & Analogies

Imagine a giant underground worm that smoothly chews through the earth while simultaneously building a tunnel for trains to pass through. Just like this worm, robotic TBMs tirelessly work below the ground, creating paths for transportation without disrupting the surface above.

Functionality of Robotic TBMs

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

These machines utilize advanced technology to monitor their position, manage the digging process, and ensure the precise construction of tunnel segments.

Detailed Explanation

Robotic TBMs are equipped with sophisticated sensors and software that allow them to navigate accurately through the earth. They can analyze the geology of the area, adjust their digging strategy based on real-time conditions, and ensure precise placement of tunnel lining segments. This automation is crucial for maintaining the integrity of the tunnel and ensuring safety standards are met.

Examples & Analogies

Think of a skilled driver using GPS to navigate through a city. Just like the driver uses maps to find the best route and avoid obstacles, robotic TBMs use their internal systems to determine the best path underground while ensuring they don’t hit anything dangerous.

Advantages of Using Robotic TBMs

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The use of robotic TBMs leads to increased efficiency, reduced labor costs, and enhanced safety for workers.

Detailed Explanation

Robotic TBMs revolutionize the tunneling process by eliminating many traditional challenges. They operate efficiently, allowing construction to proceed faster than if done manually. Since these machines can work continuously without needing breaks, they also reduce labor costs. Moreover, because they operate underground, they keep human workers safe from potential hazards associated with tunneling, such as cave-ins or exposure to harsh conditions.

Examples & Analogies

Imagine an astonishing machine that can dig a long tunnel while humans safely watch from above. This is comparable to how robotic TBMs function, where the advanced machine does the labor-intensive work, reducing the human burden and dangers of traditional tunneling.

Key Concepts

-

Robotic TBMs: Automated machines that excavate tunnels while installing support systems.

-

Efficiency: The ability of TBMs to operate continuously, enhancing construction speed.

-

Safety: TBMs reduce the risks involved in traditional tunneling by reducing human exposure in dangerous environments.

Examples & Applications

The use of TBMs in the construction of the Delhi Metro, where they significantly reduced construction time compared to traditional methods.

In the construction of Boston's Big Dig project, TBMs helped minimize surface disruption in urban areas.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Tunnels are made with TBMs, drilling day and night, making underground paths feel just right.

Stories

Once in a busy city, a robotic TBM began its journey under the streets, helping to build a metro for all to see, while keeping everyone above ground free.

Memory Tools

Remember 'TUNNELS' - TBMs Use Navigation for New Engineering in Large Spaces.

Acronyms

SPEED - Safety, Precision, Efficiency, Effectiveness, and Durability in tunneling.

Flash Cards

Glossary

- Robotic Tunnel Boring Machines (TBMs)

Sophisticated machines designed to excavate tunnels by navigating through underground materials while constructing tunnel segments.

- Automation

Technology that performs tasks automatically with minimal or no human intervention.

- Infrastructure Projects

Large-scale construction initiatives that include roads, bridges, and underground tunnels.

Reference links

Supplementary resources to enhance your learning experience.