Open Loop vs Closed Loop

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Understanding Open Loop Control

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, let's dive into open-loop control systems. This type of system operates without feedback, meaning once it begins a task, it doesn't check to see how accurately it’s being completed. Can anyone give me an example of an open-loop system?

Could a microwave be one? It just cooks for a set time without checking the food.

Exactly! A microwave is a great example. It doesn't adjust cooking time based on the temperature of the food. So remember, we can think about it as 'set and forget'. What happens if the microwave's cooking time is incorrect?

The food might be undercooked or overcooked!

Right! That's one limitation of open-loop systems. They can’t correct their actions based on outcomes. Let’s move on to closed-loop systems.

Exploring Closed Loop Control

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s discuss closed-loop control. These systems use feedback from sensors to make adjustments during operation. Can anyone think of a robotic example that utilizes this type of control?

How about a robotic arm that can adjust its position based on how it sees where it is going?

Great example! The robotic arm has sensors that provide real-time data, allowing it to adjust for precision. We can use the acronym 'F.A.C.E' to remember the benefits of closed-loop systems: Feedback, Adaptability, Control, and Efficiency. Why do you think adaptability is important?

It can help the robot fix mistakes and improve its movements over time!

Exactly! That adaptability can significantly enhance performance. In summary, closed-loop systems are more responsive and accurate than open-loop systems due to their feedback mechanism.

Comparison of Control Systems

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let’s compare open-loop and closed-loop systems directly. What are some key differences you recall between the two?

Open-loop doesn’t take feedback, and closed-loop does.

Closed-loop can correct errors while open-loop can't.

Correct! Open-loop systems are simple and efficient for straightforward tasks. However, closed-loop systems, despite their complexity, provide adaptability. This makes them suitable for tasks requiring precision. Which system do you think is better overall?

It depends on the application! For precise tasks, closed-loop is better, but for basic tasks, open-loop works just fine.

Great observation! So, to summarize: open-loop systems are fixed, while closed-loop systems can adapt based on performance.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

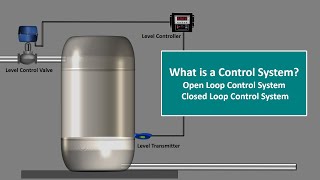

The section examines the concepts of open-loop and closed-loop control systems in robotics. Open-loop systems operate without feedback, meaning they execute pre-defined commands without evaluating their outcomes, while closed-loop systems utilize sensors to gather real-time data, enabling adaptive control and error correction.

Detailed

Open Loop vs Closed Loop

In robotics, control systems play a crucial role in determining how machines perform and adapt to their environments. This section addresses two primary types of control systems: Open Loop and Closed Loop.

Open Loop Control

- Definition: Open-loop systems operate based on predefined instructions without real-time feedback. They complete tasks based on the initial programming without evaluating performance or making adjustments based on outcomes.

- Example: Early CNC machines are examples of open-loop systems where the sequence of operations is set but there’s no mechanism to measure accuracy or success.

Closed Loop Control

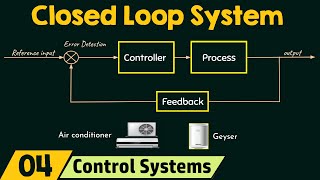

- Definition: Closed-loop systems use sensors to monitor the system’s performance continuously and can adapt their actions based on feedback. This allows for real-time corrections and improved accuracy.

- Example: Modern robotic arms that employ sensors to make adjustments during operation to ensure precision exemplify closed-loop systems.

Importance

Understanding the differences between these two control systems is essential for the development of more efficient and accurate robotic applications. Closed-loop systems are vital for tasks requiring high levels of precision and adaptability.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Understanding Open Loop Control

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Open Loop Control: Earlier machines had fixed operations without feedback (e.g., early CNC machines).

Detailed Explanation

Open loop control systems operate without feedback. That means they follow a set of pre-defined instructions and do not react to changes in their environment. An example of this is early computer numerical control (CNC) machines, which performed tasks based on a fixed sequence without considering if their actions were successful or accurate. If something went wrong during operation, the machine would not correct itself, leading to possible errors or inefficiencies.

Examples & Analogies

Imagine a washing machine that only follows a set program without sensing the amount of clothes inside it. If the machine is overloaded or too lightly filled, it wouldn’t adjust its water level or washing time. It simply operates in a predetermined manner, which might not produce the intended wash quality.

Understanding Closed Loop Control

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Closed Loop Control: Uses sensors to provide real-time feedback, allowing for error correction and adaptive control.

Detailed Explanation

In contrast, closed loop control systems integrate feedback from sensors that monitor the machine's output and environment. This feedback allows the system to make adjustments in real-time, correcting any errors. For example, in a closed loop control system, if a robotic arm misplaces an item, sensors will detect this and signal the arm to reposition itself accurately. This results in enhanced precision and adaptation to different scenarios.

Examples & Analogies

Think of a thermostat that controls the heating in your home. It measures the current temperature and adjusts the heating system accordingly. If it gets too cold, the thermostat switches on the heater, and if it’s too warm, it turns it off. This constant feedback loop ensures the home stays at a comfortable temperature, demonstrating how closed loop systems can function effectively.

Key Concepts

-

Open Loop Control: Systems operate without feedback.

-

Closed Loop Control: Systems utilize feedback for adaptability and accuracy.

-

Feedback: Data used to make real-time adjustments.

Examples & Applications

A microwave oven operates on an open-loop control system by cooking for a set time without checking food conditions.

A modern robotic arm adjusts its movements in real-time based on sensor feedback, exemplifying closed-loop control.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Open Loop is set and done, without checks, it's just for fun.

Stories

Imagine a robot, Bob, who is given a task to paint a wall. He doesn’t look back to check if he’s painted well. That’s Bob with an open loop! Now imagine if Bob had a camera to check his work, adjusting his strokes – he’s now a closed loop robot!

Memory Tools

F.A.C.E: Feedback, Adaptability, Control, Efficiency for Closed Loop systems.

Acronyms

OL = Open Loop; CLC = Closed Loop Control.

Flash Cards

Glossary

- Open Loop Control

A type of control system that executes pre-defined tasks without feedback.

- Closed Loop Control

A control system that uses real-time feedback to adjust its actions and improve accuracy.

- Feedback

Information returned to the control system about its output, allowing adjustments.

Reference links

Supplementary resources to enhance your learning experience.