Challenges in SHM Automation

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Sensor Calibration and Durability

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's start by talking about sensor calibration and durability. Why do you think it's crucial for SHM systems?

It’s important because if the sensors are not calibrated, the data they provide can be inaccurate, right?

Exactly! Inaccurate data can lead to false alarms or missed detections of real issues. Regular calibration ensures that the sensors provide reliable readings.

But what about durability? How does that affect SHM?

Good question! Sensors must withstand environmental changes and degradation without failing. This is crucial for long-term monitoring. Think about it: environments like bridges or skyscrapers expose sensors to vibrations, temperature changes, and moisture. Can you think of any examples?

Maybe sensors on a bridge would be at risk due to weather conditions?

Exactly! Summarizing our discussion: reliable sensor calibration is vital for data accuracy, and ensuring sensor durability is key for effective long-term monitoring.

Power Supply Challenges

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let’s discuss power supply challenges. Why might this be a problem for SHM systems in remote areas?

Because if there’s no easy way to get electricity, the sensors can’t work?

Absolutely! Many sensors need a reliable power source, which can be a significant hurdle in isolated locations. What are some potential solutions you can think of?

Perhaps using solar panels or battery backups could help?

Great thinking! Utilizing renewable energy sources can help maintain operations without constant power supply concerns. Remember, ensuring power stability in these locations is essential for continuous monitoring.

Data Overload and Real-Time Processing

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s dive into the concept of data overload. With multiple sensors collecting continuous data, what challenges do you think arise?

There could be too much data to process, possibly leading to delayed responses?

Exactly! The influx of data can overwhelm systems that aren't designed to handle large volumes efficiently. What methods do you think exist to manage this?

Maybe using data filters or real-time processing algorithms could help?

Right! These methods allow for effective analysis even during high data influx, ensuring that important alerts aren't overlooked. So, efficient data management is key in SHM automation.

Cybersecurity and Data Integrity

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s discuss cybersecurity. What do you think makes this a critical issue in SHM systems?

If hackers can access the data, they might change critical alerts or even shut down the monitoring?

Exactly! Ensuring data integrity and protecting systems from cyber threats is paramount. What practices can be put in place to enhance security?

Maybe using encrypted data communications would help?

Yes! Encryption can help safeguard against unauthorized access. In summary, focusing on cybersecurity is crucial for maintaining trust in SHM systems.

Cost of Deployment and Maintenance

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Lastly, let’s talk about the financial challenges of deploying SHM systems. Why do costs matter?

High costs might limit the number of SHM systems we can implement.

Exactly! Budget constraints can restrict the adoption of advanced technologies. Can you think of ways to make them more affordable?

Maybe smaller investments over time or phased implementation could work?

Great idea! Systematic approaches can help mitigate costs while still enhancing infrastructure safety. In conclusion, addressing the cost of both deployment and maintenance is vital for SHM success.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Several key challenges impact the effective automation of structural health monitoring systems, including issues related to sensor calibration, power supply, data management, cybersecurity, and the financial aspects of deployment and maintenance.

Detailed

Detailed Summary

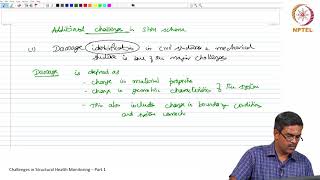

The process of implementing Structural Health Monitoring (SHM) systems involves various automated technologies that strive to improve the safety and longevity of civil structures. However, automating these systems comes with significant challenges. Critical issues include:

- Sensor Calibration and Durability: Accurate sensor readings are crucial for damage detection. Sensors must be calibrated regularly to ensure reliable performance, and their durability in diverse environments is essential, as exposure to various conditions may degrade their functionality.

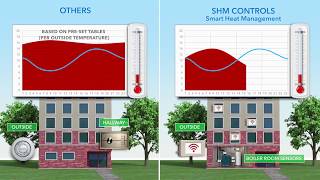

- Power Supply in Remote Environments: Many SHM systems are deployed in hard-to-reach areas, making consistent power supply an issue. Ensuring that sensors and devices can operate independently or efficiently is vital for continuous monitoring.

- Data Overload and Real-Time Processing: The integration of numerous sensors leads to a massive influx of data. Efficient processing techniques need to be developed to handle this data overload while maintaining real-time performance to enable timely decision-making.

- Cybersecurity and Data Integrity: With increased reliance on wireless communication and cloud-based systems, ensuring data security and privacy is paramount. Preventing unauthorized access and ensuring the integrity of data is critical for trust in SHM systems.

- Cost of Deployment and Maintenance: Budget constraints can limit the implementation of advanced automated SHM systems. The initial costs and the ongoing maintenance must be carefully balanced against the long-term benefits of these systems.

Understanding these challenges is essential for developing robust SHM automation solutions, paving the way for safer and more efficient infrastructure management.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Sensor Calibration and Durability

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Sensor calibration and durability

Detailed Explanation

Sensor calibration refers to the process of ensuring that the sensors used in Structural Health Monitoring (SHM) accurately measure the parameters they are designed to monitor, such as strain, temperature, or vibrations. Sensors can degrade over time due to environmental factors, leading to inaccurate readings if not properly calibrated and maintained. The durability of sensors is crucial, especially in harsh conditions, as factors such as moisture, temperature fluctuations, and physical impacts can affect their performance.

Examples & Analogies

Think of a sensor like a thermometer in your house. If it’s not calibrated correctly, it might show that your room is 20 degrees when in reality it is 25 degrees. Similarly, if a sensor in a bridge is not functional or damaged, it might not accurately report the level of strain on the structure, leading to poor maintenance decisions.

Power Supply in Remote Environments

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Power supply in remote environments

Detailed Explanation

In many cases, SHM systems are deployed in remote locations where access to conventional power sources is limited. This presents a challenge for continuous monitoring, as sensors need a reliable power supply to operate. Solutions often include battery-operated sensors or energy harvesting technologies, such as solar panels or piezoelectric generators, but these methods can still pose limitations regarding how long the system can operate without maintenance or replacement.

Examples & Analogies

Consider using a smartphone while camping in a remote area. You might have limited access to charging stations. Similarly, sensors in a remote bridge or dam need to 'power up' somehow without a regular power source to keep monitoring the structure.

Data Overload and Real-Time Processing

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Data overload and real-time processing

Detailed Explanation

SHM systems can generate a massive amount of data from numerous sensors continuously monitoring various structural parameters. This can lead to data overload, where the volume of information becomes too large for proper analysis and decision-making. Real-time processing is needed to filter and analyze the data efficiently, but this requires advanced computational resources and algorithms to ensure that critical information is not missed, and quick decisions can be made regarding the safety of the structures.

Examples & Analogies

Imagine you're at a concert trying to listen to the main band play while everyone around you is shouting. While the music (important data) is essential, the noise (unnecessary data) can overwhelm you. Similarly, in SHM, we need systems that can 'tune out' the extra noise and focus on what truly matters for the safety of the structure.

Cybersecurity and Data Integrity

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Cybersecurity and data integrity

Detailed Explanation

As SHM systems often rely on internet-connected devices and cloud storage, they become vulnerable to cyber threats. Protecting the integrity and confidentiality of the data collected is paramount. Cybersecurity measures must be implemented to prevent unauthorized access, data breaches, and manipulation of the structural health data, ensuring that the information used for maintenance decisions is trustworthy and accurate.

Examples & Analogies

Think about your bank account information. Just like you would want to protect your money and personal information from hackers, SHM systems require robust security protocols to keep their data safe from cyber threats that could mislead or sabotage infrastructure safety assessments.

Cost of Deployment and Maintenance

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Cost of deployment and maintenance

Detailed Explanation

Implementing SHM systems can be costly, not only in terms of initial deployment but also regarding ongoing maintenance. The cost involves purchasing equipment, installation, training personnel, and periodic calibration and checks. Organizations must weigh these costs against the benefits of enhanced safety, reduced maintenance costs, and prolonged structural life to justify the investment in automation for SHM.

Examples & Analogies

Like installing a security system in your home—initial costs for cameras and setup can be high, but the peace of mind and potential savings from preventing theft can justify the expense. Similarly, investing in SHM automation can protect infrastructure and save money in the long run.

Key Concepts

-

Sensor Calibration: Essential for accuracy in SHM data collection.

-

Data Overload: The challenge of processing large volumes of data in real-time.

-

Cybersecurity: Protecting SHM data from unauthorized access and breaches.

-

Power Supply: Critical for the continuous operation of SHM systems, especially in remote areas.

-

Cost of Deployment: Financial challenges in implementing SHM technologies.

Examples & Applications

An example of sensor calibration is adjusting a strain gauge on a bridge to ensure it accurately measures strain under different load conditions.

Utilizing solar panels to power sensors installed on remote infrastructure helps maintain continuous monitoring without regular human intervention.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

For sensor durability and calibration's might, Accurate readings help structures stay right!

Stories

Imagine a bridge where sensors buzz, but one part fails as the calibration does. The bridge sways at night, with no data to cite, leading to dangers unseen out of sight.

Memory Tools

Remember 'S.P.C.C.' for the challenges in SHM: Sensor calibration, Power supply, Cybersecurity, and Cost concerns.

Acronyms

C.P.D.C. - Calibration, Power supply, Data overload, Cybersecurity are critical for SHM automation.

Flash Cards

Glossary

- Sensor Calibration

The process of adjusting and fine-tuning the sensor readings to ensure accurate data collection.

- Data Overload

A situation where the volume of data exceeds the processing capabilities of the system, leading to delayed responses.

- Cybersecurity

The practice of protecting systems and networks from digital attacks, ensuring data privacy and integrity.

- Power Supply

The source of electrical energy required for sensors and devices to operate, particularly in remote locations.

- Cost of Deployment

The financial resources required for the installation and implementation of SHM systems.

Reference links

Supplementary resources to enhance your learning experience.