Human-Robot Collaboration in Prefabricated Construction: KUKA Robotics with Skanska

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Overview of Human-Robot Collaboration

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're discussing the fascinating world of human-robot collaboration in prefabricated construction, particularly how KUKA Robotics collaborates with Skanska. Can anyone tell me what they think the primary benefits of using robotics in this field are?

I think robots can help with tasks that are repetitive and require precision.

They might also speed up the construction process!

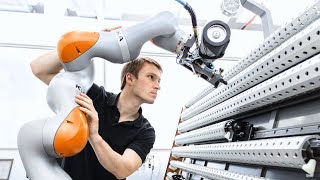

Exactly! Robots can enhance productivity and accuracy while reducing human fatigue. In our case study, KUKA robotic arms handle high-precision tasks like cutting and welding, enabling human workers to focus on oversight and logistics.

So, humans still play an important role even with robots around?

Absolutely! This is a prime example of collaboration where both humans and robots bring their strengths to the table. Let's remember: HRC - Human-Robot Collaboration!

Application during COVID-19

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's dive deeper into the practical application during COVID-19. How do you think prefabricated construction helped in this situation?

I think it’s about meeting urgent healthcare needs with quick construction.

Exactly! KUKA robots facilitated rapid construction of modular hospitals. What might be an outcome of such technology during a crisis?

It probably reduces fabrication errors and speeds up delivery!

Right again! We saw a 40% reduction in fabrication errors, which is quite significant. This highlights the importance of robotics in construction not just for speed but also for safety and quality.

Human roles in the collaboration

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s focus on human roles in this collaboration. What do you think workers are doing while the KUKA robots handle the physical tasks?

They probably manage materials and handle errors, right?

Yes! Humans provide inputs and logistics, ensuring everything runs smoothly. Remember, their oversight is critical in avoiding errors. It’s like a team sports approach where everyone has a role!

So, we can think of this as teamwork between machines and people?

Exactly! This collaboration is essential for achieving efficiency and quality, especially in a structured environment like a factory.

Significance in construction

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Lastly, let’s talk about the significance of HRC in construction overall. How do you see it changing the industry?

I think it will revolutionize how we build things, making it faster and safer.

Great point! The incorporation of robotics leads to less human error and enhances worker safety. The key takeaway is that HRC not only improves efficiency but also reshapes the way we approach construction.

So, it’s not just about technology; it’s about improving our work environments too!

Absolutely! That's a powerful lesson about the value of collaboration in advancing our capabilities in construction.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The collaboration between KUKA Robotics and Skanska emphasizes enhancing productivity in prefabricated construction. The KUKA robotic arms are employed to automate high-precision tasks while human workers handle logistics and error management. The application has been proven especially effective during the rapid construction of modular hospital units in response to COVID-19, resulting in significant reductions in fabrication errors and improved efficiency.

Detailed

In this section, we explore the collaboration between KUKA Robotics and Skanska in the context of prefabricated construction. KUKA robotic arms are integrated into the prefabrication process to handle repetitive and precision-intensive tasks such as cutting, welding, and assembling steel components for modular structures. Human workers play a critical role by providing inputs, managing material logistics, and supervising error handling to ensure quality. Particularly noteworthy is the application of this technology during the COVID-19 pandemic, where the rapid construction of hospital modules was necessary. This collaboration led to a 40% reduction in fabrication errors and significantly improved the speed-to-market for urgent infrastructure needs, demonstrating the potential for robotics to enhance worker safety and efficiency in factory environments. The successful implementation of KUKA robotics shows how human-robot collaboration can address modern challenges in construction.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Project Summary

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

KUKA robotic arms were deployed in Skanska’s prefabrication facilities for cutting, welding, and assembling steel components for modular structures.

Detailed Explanation

In this project, KUKA robotic arms were used at Skanska's facilities to help with tasks like cutting, welding, and assembling steel parts that are essential for building modular structures. Modular construction involves creating sections of a building off-site and then assembling them on-site, allowing for greater efficiency and speed in construction.

Examples & Analogies

Imagine building model kits where various parts must fit together precisely to create the final structure. In this case, the KUKA robots are like skilled helpers that handle repetitive and precise tasks, allowing human workers to focus on more complex aspects of the building process.

Human-Robot Division

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Humans provide inputs, material logistics, and supervise error handling.

• KUKA robots carry out repetitive high-precision tasks.

Detailed Explanation

In this collaboration, humans play a critical role by managing logistics (like ensuring materials are available) and supervising the robots to handle errors that may arise during the manufacturing process. The KUKA robots, on the other hand, are tasked with performing repetitive and precise tasks, which are essential for maintaining the quality and efficiency of production in prefabrication.

Examples & Analogies

Think of a bakery where bakers (humans) oversee the process, measuring out ingredients, while a dough mixer (robot) does the repetitive work of mixing. The bakers ensure that everything runs smoothly and correctly, while the mixer ensures each dough batch is consistent.

Site Application: Modular Hospital Units During COVID-19

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Rapid construction of hospital modules with high precision.

Detailed Explanation

During the COVID-19 pandemic, there was an urgent need for additional hospital space. The KUKA robots helped build prefabricated hospital units quickly and accurately. This rapid construction was crucial in ensuring that healthcare facilities could accommodate more patients and respond effectively to the crisis.

Examples & Analogies

It’s like preparing emergency supplies in advance for a natural disaster. The quicker and more accurately those supplies are organized, the better prepared the community will be to face the challenge.

Outcomes

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• 40% reduction in fabrication errors.

• Improved speed-to-market for urgent infrastructure needs.

• Enhanced worker safety in factory environments.

Detailed Explanation

The use of KUKA robotics in this project led to significant improvements: a 40% reduction in errors during fabrication meant that fewer parts had to be reworked, saving time and resources. Additionally, the quick assembly of modular units allowed for faster deployment of critical infrastructure, vital during health emergencies. Furthermore, by using robots to handle dangerous and repetitive tasks in the factory, workers experienced a safer working environment.

Examples & Analogies

Imagine organizing a big event. If you have a team of helpers (robots) to handle repetitive tasks like setting up tables, the chances of making mistakes decrease, which allows the event to start smoothly and on time, just like how KUKA robots improve efficiency and accuracy in hospital construction.

Key Concepts

-

Integrating robotics into construction enhances productivity and reduces errors.

-

Human oversight is critical for ensuring quality and safety in collaborative environments.

-

The usage of KUKA robots exemplifies the benefits brought by automation in urgent scenarios.

Examples & Applications

The rapid construction of modular hospital units during the COVID-19 pandemic effectively showcased KUKA's capabilities.

Skanska's prefabrication facilities highlighted the efficiency gains from integrating robotics in high-precision tasks.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

KUKA's keen, machines are clean, helping build the unseen.

Stories

Imagine a construction site where robots cut and weld while humans plan, making a new hospital rise in days, not months.

Memory Tools

KUKA - Keep Understanding Kinematic Automation.

Acronyms

HRC - Humans Role Collaboration.

Flash Cards

Glossary

- KUKA Robotics

A company specializing in robotic automation solutions.

- HumanRobot Collaboration (HRC)

The integration of robots and humans working together in tasks.

- Prefabricated Construction

Construction methods that involve assembly of structures from pre-manufactured components.

- Modular Structures

Buildings constructed using repeated sections or modules.

- Fabrication Errors

Mistakes that occur during the manufacturing or construction process.

Reference links

Supplementary resources to enhance your learning experience.