Risk Assessment in HRI

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Hazard Identification

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's begin with hazard identification, which is the first step in risk assessment. Can anyone tell me what hazards in human-robot interaction might look like?

I think it involves figuring out what can go wrong when a robot is working near humans.

Exactly, Student_1! It’s about spotting tasks that involve interaction between humans and robots. For example, a robot lifting heavy materials could lead to mechanical failures injuring nearby workers. Can anyone think of other hazards?

What about software failures that might cause the robot to act unexpectedly?

Great point, Student_2! Software glitches can also lead to serious risks. So remember—hazard identification is about assessing potential mechanical and software failures.

Risk Estimation

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Moving on to risk estimation—this phase involves figuring out two main things: how severe the potential injury could be and how likely it is to happen. Student_3, could you elaborate on why understanding severity is crucial?

Sure! Knowing how severe an injury can be helps prioritize which risks we need to address first!

Exactly! Prioritizing is key! Now, let’s discuss the probability of occurrence. What factors can influence this?

Maybe how often humans are exposed to the robot during work?

You're absolutely right, Student_4! The frequency and duration of exposure are significant in weighing the risk.

Risk Reduction Measures

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let’s explore how we can reduce the risks associated with HRI. Can anyone suggest some measures that can be taken?

We could redesign the robots to prevent mechanical failures!

Good idea, Student_1! Design modifications are vital. What about technical implementations?

Adding more sensors could help detect human presence and prevent accidents.

Absolutely! Additional sensors and controls are essential. How about administrative measures?

Training workers to recognize robot behavior and risks could be very effective!

Exactly! Training is a key component of risk reduction. So, to summarize, hazard identification, risk estimation, and reduction measures together create a robust framework for safety in HRI.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section emphasizes the importance of risk assessment throughout the deployment of robotic systems in HRI. It covers the phases of hazard identification, risk estimation, and risk reduction measures to safeguard human workers against potential mechanical and software failures.

Detailed

Risk Assessment in HRI

Effective risk assessment is vital at every stage of robotic system deployment in human-robot interaction (HRI). It encompasses three core processes:

1. Hazard Identification involves pinpointing tasks that entail human-robot interaction and evaluating risks stemming from mechanical or software failures.

2. Risk Estimation assesses the severity of possible injuries, the likelihood of their occurrence, and the duration of exposure to risks.

3. Risk Reduction Measures propose solutions such as redesigning systems, adding sensors and controls, and implementing administrative protocols like worker training and warning signage to minimize encountered risks.

This comprehensive approach ensures the safety and effectiveness of robotic systems utilized in civil engineering and other fields.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Hazard Identification

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

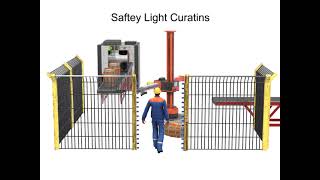

• Identifying tasks that involve robot-human interaction

• Assessing the potential for mechanical or software failure

Detailed Explanation

The first step in risk assessment is hazard identification. This involves recognizing specific tasks where humans and robots interact. For instance, in a construction site, tasks that include a robot lifting heavy materials while humans are nearby must be identified. Additionally, it's critical to evaluate the potential for failures in both mechanical systems (like a robot’s arm that could malfunction) and software systems (where a glitch could make the robot move unexpectedly). By identifying these hazards, we can begin to understand where the risks arise.

Examples & Analogies

Imagine you are planning a picnic and are concerned about potential hazards like bees or bad weather. Just like checking for these threats, in a work environment with robots, we must identify specific tasks where the robots could pose risks to humans.

Risk Estimation

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Evaluating the severity of potential injury

• Probability of occurrence

• Frequency and duration of exposure

Detailed Explanation

After identifying hazards, the next step is risk estimation. This involves evaluating how severe an injury could be if an accident were to happen. For example, if a robot dropped a heavy load, could it cause serious injury? Additionally, we assess the likelihood of such an injury occurring and how often workers could be exposed to these hazards during their tasks. This is crucial for prioritizing safety measures based on the level of risk.

Examples & Analogies

Think about how a lifeguard assesses the safety of a swimming pool. They consider how deep the water is (severity of injury), how many kids are playing (probability), and how many children are at the pool each day (exposure frequency). Similarly, risk estimation looks at how dangerous the environment can become due to robots.

Risk Reduction Measures

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

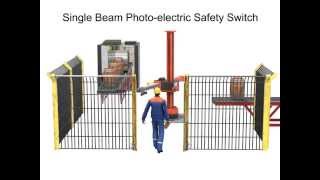

• Design modifications

• Additional sensors and controls

• Administrative measures like training and signage

Detailed Explanation

Once risks are identified and estimated, we move to risk reduction measures. This means making changes to either the robots or the environment to make it safer. For instance, design modifications could involve adding guards to robots to protect workers from moving parts. Additional sensors can detect human presence to prevent accidents, and administrative measures might include training workers about safe practices and placing signs in hazardous areas. Implementing these measures helps ensure a safer interaction between humans and robots.

Examples & Analogies

Consider how construction sites have safety practices like hard hats, safety cones, and training sessions for workers. Just as these measures reduce risks of accidents, in HRI, modifications and training help protect workers from robots.

Key Concepts

-

Hazard Identification: The process of identifying potential risks in HRI.

-

Risk Estimation: Analyzing both the severity of possible injuries and the likelihood of their occurrence.

-

Risk Reduction Measures: Actions taken to mitigate identified risks.

Examples & Applications

Identifying tasks like robotic welding that may pose risks of fire hazards.

Assessing the probability of a robot's software error occurring during operations.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Identify, Estimate, Reduce—these are the steps to safely cruise!

Stories

Imagine a busy construction site where a robot is lifting heavy loads. The workers begin by identifying all possible risks linked to the robot, calculating how often these hazards occur and their severity. They implement training sessions with visual signs to guide everyone safely around the robot.

Memory Tools

H.E.R.: Hazard identification, Estimation, Reduction.

Acronyms

HRI

Human-Robot Interaction—embedded in risk assessment!

Flash Cards

Glossary

- Hazard Identification

The process of identifying tasks involving human-robot interaction and assessing potential risks of mechanical or software failures.

- Risk Estimation

The evaluation of the severity of potential injury and the likelihood of its occurrence.

- Risk Reduction Measures

Strategies designed to lower the risk of injury, including design modifications, added sensors, and worker training.

Reference links

Supplementary resources to enhance your learning experience.