Safety Design Principles

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Inherently Safe Design

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Inherently Safe Design is all about making design choices that limit risks. What are some risks that come to mind when you think about robots in construction?

Uncontrolled movement might hurt workers.

Exactly! One way to mitigate this is to limit the maximum speed and force of the robots. What other design features do you think can help?

Using rounded edges on the robot's arms and grippers?

Great point! Rounded edges and soft materials help reduce injury if there’s accidental contact. It's all about observing the principle 'Safety First'.

Can anyone summarize what we've learned about Inherently Safe Design?

We should limit robot speed and use soft materials to make robots safer.

Protective Measures

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Moving on to Protective Measures. Why do you think emergency stop mechanisms are crucial?

They help to stop the robot quickly if something goes wrong!

Absolutely! Additionally, safety-rated monitored stops ensure reliability. Can anyone explain what guarding systems like laser curtains do?

They create a barrier so workers don’t accidentally walk into the robot's workspace.

Correct! Guarding systems are vital to prevent accidents, allowing the robot to operate safely around humans. Let’s remember the acronym P.E.S. - Protective Measures = Emergency Stops + Safety-rated stops + Guarding.

Information for Use

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's focus on Information for Use. Why do you think clear alerts are important for robot operation?

They help workers know when a robot is on or in danger!

Exactly! Visual and auditory alerts ensure that workers are aware of potential hazards. What else can help improve safety measures?

User manuals with safety warnings could help.

That's a great point! Manuals play a critical role in educating users about the robot’s capabilities and risks. Let's summarize: Alerts + Manuals = Safety Awareness!

Additional Protection

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Lastly, let’s discuss Additional Protection. What is the role of Personal Protective Equipment in a robot-driven construction site?

It protects workers from accidents with robots.

Exactly! PPE serves as a last line of defense. Additionally, redundant safety systems enhance reliability. Can someone explain what redundant systems do?

They provide backup measures if the primary one fails?

Exactly! Remember, 'Two is better than one' in ensuring safety! Recap: PPE + Redundant systems = Enhanced Safety.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The safety design principles focus on creating robotic systems that reduce risks to human operators through inherent design features, protective measures, and effective information dissemination. Key elements include inherently safe design, emergency stops, user information, and personnel protective equipment (PPE).

Detailed

Safety Design Principles

This section discusses crucial principles for designing robotic systems that prioritize human safety. As robots become integral to civil engineering projects, their design must minimize potential hazards while enhancing operational efficiency. The following key principles are addressed:

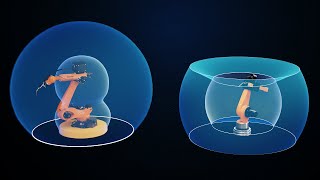

1. Inherently Safe Design

- This principle involves engineering robots to limit maximum speed and force, aiming to reduce the chances of injury.

- The use of rounded edges and soft materials on robot grippers can minimize injury risk during accidental contacts.

2. Protective Measures

- Emergency stop mechanisms are vital for allowing immediate robot shutdown in case of danger.

- Safety-rated monitored stops ensure that robots stop safely and reliably when a safety condition is breached.

- Implementing guarding systems, such as cages and laser curtains, can physically separate humans from robot operation zones, providing another layer of safety.

3. Information for Use

- Clear visual and auditory alerts are critical for communicating robot status and warnings to human operators.

- User manuals should be readily available, highlighting potential hazards and safety procedures associated with the robotic systems.

- On-device displays can provide real-time status updates, facilitating better awareness and timely responses from human workers.

4. Additional Protection

- Personal Protective Equipment (PPE) is essential for ensuring worker safety in environments where robots are used.

- Incorporating redundant safety systems, such as dual-sensor cross-verification, can serve as backup measures, enhancing reliability and reducing potential failure points.

These principles collectively embody a proactive approach to safety in human-robot interaction, ensuring that robotic systems contribute positively to civil engineering applications without compromising human safety.

Youtube Videos

![How to get started with Robotics? [MUST KNOW TIPS] Building Robots for Beginners](https://img.youtube.com/vi/NRj6gzah7JA/mqdefault.jpg)

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Inherently Safe Design

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Limit maximum speed and force of robot

• Use of rounded edges and soft materials on arms or grippers

Detailed Explanation

Inherently safe design focuses on creating robotic systems that minimize risk from the very start. One of the key principles is to limit the maximum speed and force of robots. This means that even in the worst-case scenario, the robot will not exert excessive force that could harm a human. Additionally, using rounded edges and soft materials for the robot’s arms or grippers helps to prevent injuries from sharp edges or hard surfaces, making interactions safer.

Examples & Analogies

Think of a robot arm like a child's toy. If you have a toy made with soft foam and rounded shapes instead of hard plastic with sharp edges, it is much safer for children to play with. The same principle applies to robots in a work environment; by designing them with safety in mind, we ensure that even if they accidentally bump into someone, they won't cause serious harm.

Protective Measures

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Emergency stop mechanisms

• Safety-rated monitored stops

• Guarding systems (e.g., cages, laser curtains)

Detailed Explanation

Protective measures are essential to ensure human safety around robots. Emergency stop mechanisms allow operators to quickly halt robotic operations in case of an emergency. Safety-rated monitored stops are designed to ensure that the robot will not move even if an operator temporarily breaks the automation protocols. Additionally, guarding systems such as cages or laser curtains are put in place to physically separate humans from dangerous robotic movements.

Examples & Analogies

Consider a powerful factory machine that has an emergency button that stops it immediately if something goes wrong. Just like having a safety fence around a construction site prevents people from entering dangerous areas, laser curtains around robots ensure that humans are alerted if they get too close, stopping the robot before an accident can happen.

Information for Use

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Clear visual/auditory alerts

• User manuals and warnings

• On-device displays for robot status

Detailed Explanation

Providing clear information for use is crucial for safe human-robot interaction. This includes having visual and auditory alerts that inform users about the robot's status or any hazards. User manuals give instructions on how to operate the robot safely, while on-device displays provide real-time updates on what the robot is doing, helping to keep operators informed and aware of their surroundings.

Examples & Analogies

Imagine driving a car that has a dashboard showing speed and warning lights. If the car has an issue, a light might flash, or it might beep, alerting the driver to take action immediately. Similarly, robots must communicate with humans about their operations to prevent confusion or accidents.

Additional Protection

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Personal protective equipment (PPE) for workers

• Redundant safety systems (e.g., dual-sensor cross-verification)

Detailed Explanation

Additional protection measures enhance safety in environments where humans work alongside robots. Personal protective equipment (PPE) like helmets, goggles, and gloves are essential for workers to protect them from any unexpected incidents. Furthermore, redundant safety systems, such as dual-sensor cross-verification, ensure that if one safety feature fails, another layer of protection is still in place to prevent accidents.

Examples & Analogies

Think of fire alarms in a building. Having a single alarm might suffice, but many buildings have multiple alarms and sprinklers to ensure safety. Similarly, just as workers wear hard hats on construction sites for protection against falling objects, robots utilize redundant safety systems to ensure that, if one safeguard fails, the others still protect everyone nearby.

Key Concepts

-

Inherently Safe Design: Limiting robot speed and using soft materials.

-

Protective Measures: Importance of emergency stops and guarding systems.

-

Information for Use: Role of alerts and user manuals in safety.

-

Additional Protection: Use of PPE and redundant safety systems.

Examples & Applications

A robot with rounded edges reducing injury risk.

Emergency stop buttons installed on industrial robots.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

When designing for safety, be smart and wise, limit speed and make edges rise!

Stories

Once, a robot in a factory had sharp edges and fast speeds, it caused several accidents. Then they redesigned it—round edges, slower speeds, and now it helps workers safely!

Memory Tools

P.E.S. = Protective Measures: Emergency Stops + Safety-rated stops + Guarding.

Acronyms

S.A.F.E. = Safety, Alerts, Features, Equipment.

Flash Cards

Glossary

- Inherently Safe Design

Design principles aimed at minimizing risks associated with robotic operations through physical and operational features.

- Protective Measures

Safety mechanisms, such as emergency stops and guarding systems, designed to prevent accidents during robot operations.

- Personal Protective Equipment (PPE)

Gear worn by workers to minimize exposure to hazards, thus enhancing safety in robotic environments.

- Redundant Safety Systems

Backup systems that provide additional safety measures to prevent failures in the primary safety systems.

Reference links

Supplementary resources to enhance your learning experience.