Challenges in Logic and Physical Synthesis

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Complexity of Multi-Objective Optimization

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we’re discussing the challenges in logic and physical synthesis. Let’s start with the complexity of multi-objective optimization. Who can tell me what this means?

I think it refers to balancing different needs, like timing and power.

Exactly, Student_1! Optimizing for power, performance, and area often conflict with each other. This is commonly known as the PPA dilemma. Does anyone know why this is particularly challenging in large designs?

Is it because there are so many components to manage?

Precisely! As designs grow, the interactions between components become increasingly complex, making it difficult to find an optimal solution. Remember, this requires sophisticated optimization algorithms.

Can we have some examples of these algorithms?

Certainly! Algorithms like Genetic Algorithms and Simulated Annealing are often used in these scenarios. To sum up, effectively balancing timing, power, and area in designs remains a significant challenge.

Design Size Issues

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s move to the next challenge: design size. Why is it a problem?

Bigger designs have more parts, so they’re harder to manage?

Exactly, Student_4! More components lead to increased interactions which complicate timing closure. What do you think might be the implications of failing to achieve timing closure?

It could lead to performance issues in the final product.

Correct! Poor timing can cause the design to fail, compromising the entire chip. Balancing all components takes multiple iterations and can lead to prolonged design time.

Manufacturing Variability

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Lastly, let’s talk about manufacturing variability. Why can this be a concern for our designs?

It means that the actual performance of the chips might not match what we design for!

Exactly, Student_2! Variability can cause different parts of the chip to perform inconsistently. What strategies could we employ to deal with this?

Maybe we can design for robustness, including some tolerances?

That’s a smart approach! Designing for variability can enhance reliability in the final product.

So, we need to consider how the chip will perform in real-world conditions!

Absolutely! By acknowledging the challenges from the outset, we can implement solutions that improve the manufacturability of our designs.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section outlines significant challenges such as the complexity of multi-objective optimization, increased design sizes, and manufacturing variability that impact the effectiveness of logic and physical synthesis in VLSI design, affecting the timing, power, and area considerations.

Detailed

Challenges in Logic and Physical Synthesis

Despite technological advancements in synthesis tools, various challenges hinder the effectiveness of logic and physical synthesis in very-large-scale integration (VLSI) design. The main challenges include:

- Complexity of Multi-Objective Optimization: As designs become more intricate, balancing critical factors such as timing, power consumption, and area utilization is increasingly complex. Sophisticated algorithms are required, which can complicate the design process.

- Design Size: The growing size and complexity of designs pose significant difficulties in achieving timing closure. With larger designs, managing the interactions of components and ensuring they function optimally together becomes more difficult, often requiring additional iterative adjustments.

- Manufacturing Variability: Variability during the manufacturing process can lead to discrepancies in performance. Ensuring that designs meet specifications across different process variations remains a considerable challenge due to inherent differences during fabrication.

These challenges affect the overall quality and manufacturability of VLSI designs, requiring continuous improvement and enhancements in synthesis methodologies.

Youtube Videos

![Soft Embedded FPGA Fabrics: Top-down Physical Design and Applications [Invited]](https://img.youtube.com/vi/EnCksgkfq40/mqdefault.jpg)

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Complexity of Multi-Objective Optimization

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Complexity of Multi-Objective Optimization: Balancing timing, power, and area in large SoC designs remains a complex task, requiring sophisticated optimization algorithms.

Detailed Explanation

In the world of chip design, we aim to optimize several characteristics simultaneously — namely, timing (how fast the chip operates), power (how much energy it consumes), and area (the amount of physical space it occupies). However, finding the right balance between these factors is often tricky. For instance, making a design faster may increase power consumption or physical space usage, which can lead to challenges in meeting all specifications at once. This requires advanced algorithms capable of considering multiple objectives and finding an optimal solution that satisfies the design requirements.

Examples & Analogies

Think of baking a cake where you want it to be both delicious (taste), beautiful (appearance), and healthy (nutrition). You may have to make compromises since some ingredients that make the cake tasty or pretty might not be healthy. Just like a baker adjusting the recipe, an engineer must adjust design elements to achieve the best overall performance while meeting all criteria.

Design Size

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Design Size: As designs continue to increase in size and complexity, achieving timing closure and optimizing power and area becomes more challenging.

Detailed Explanation

As semiconductor technology advances, chips are becoming more complex and contain more components. With increased size and complexity comes the challenge of ensuring all parts work together efficiently. Specifically, achieving 'timing closure' means all signals arrive at their destinations simultaneously when required, which becomes increasingly difficult with more components. Additionally, optimizing power consumption and area usage becomes more complicated as interactions between components increase.

Examples & Analogies

It's akin to managing a larger team project at work. As more team members join, coordinating everyone's tasks and ensuring that deadlines are met becomes more challenging. You have to manage not just individual contributions but also how their work affects one another, which can complicate the overall process.

Manufacturing Variability

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

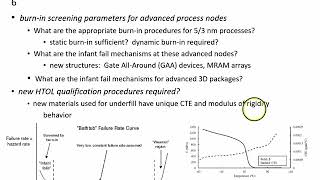

● Manufacturing Variability: Ensuring that the design meets its specifications across different process variations remains a challenge.

Detailed Explanation

In chip production, variability can occur due to differences in manufacturing processes, environmental conditions, and material properties. These variations can lead to chips that behave differently than intended, causing some to underperform while others may not function at all. Engineers must design chips that not only perform well under ideal conditions but also effectively handle the variations that occur in real-world manufacturing.

Examples & Analogies

Imagine baking cookies in different ovens. One oven might heat unevenly, leading to half-baked cookies while the other produces perfectly baked ones. Similarly, variations in the production of chips can lead to inconsistencies in performance, making it challenging to maintain quality across all manufactured units.

Key Concepts

-

Multi-Objective Optimization: Balancing timing, power, and area in VLSI designs.

-

Design Size: The increasing complexity with larger designs impacts timing closure.

-

Manufacturing Variability: Variations during manufacturing that affect design performance.

Examples & Applications

In multi-objective optimization, if we prioritize power savings, it may lead to longer delays, affecting the design's timing.

In larger designs, managing hundreds of components requires careful planning to avoid timing failures.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Power, area, timing - it’s a balancing game, Without these in sync, nothing stays the same.

Stories

Imagine a chef balancing ingredients. Too much of one spice changes the dish. Just like in chip design, too much emphasis on one optimization can spoil the overall outcome.

Memory Tools

Remember 'PAT' for Challenges: Power, Area, Timing.

Acronyms

DPM for Design size challenges

Design

Performance

Management.

Flash Cards

Glossary

- MultiObjective Optimization

The process of balancing multiple design factors, such as timing, power, and area, in engineering design.

- Timing Closure

The state at which a design meets its timing requirements, ensuring that all signals propagate within the specified time limits.

- Manufacturing Variability

The differences in the manufacturing process that can lead to variations in performance from what the design specifies.

Reference links

Supplementary resources to enhance your learning experience.