Integration of Logic and Physical Synthesis

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

The Importance of Integration in VLSI Design

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Good morning, everyone! Today, we’re going to discuss the integration of logic and physical synthesis in VLSI design. Can anyone tell me why it’s important to integrate these two processes?

Is it because both processes can affect the overall design quality?

Exactly! The outputs from logic synthesis heavily influence physical synthesis decisions. When we integrate these steps, we can better meet power, performance, and area constraints.

So, how does logic synthesis affect physical placement?

Great question! The structure determined by logic synthesis sets up the framework for placement in physical synthesis. Each standard cell's logical arrangement must consider how it will physically connect with others.

Can you give an example of this interaction?

Certainly! For instance, if logic synthesis identifies a critical timing path, physical synthesis must accommodate that route to minimize delays. This kind of interdependence is essential for successful design.

To summarize, remember that integration is key to achieving optimized designs. It ensures we’re not working in silos but rather as a unified process.

Closed-Loop Optimization

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s dive deeper into the concept of closed-loop optimization between logic and physical synthesis. Who can explain what this means?

I think it means that feedback from one process is used to inform the other?

Correct! By using feedback mechanisms, we can iteratively refine both processes. For example, say we optimize power during physical synthesis; that could lead to adjustments in logic synthesis steps to ensure they align with the new design decisions.

That sounds efficient. Does this mean we can achieve better power, performance, and area results?

Absolutely! Improved results in PPA come from this iterative collaboration, effectively leveraging timing and logical structure enhancements. It's a fundamental strategy in modern VLSI design.

As a recap, closed-loop optimization leads to better design quality and ensures we effectively meet constraints by refining our approach based on real-time feedback.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The integration of logic and physical synthesis plays a vital role in VLSI design. It highlights how logic synthesis impacts the physical placement and routing of designs, ensuring that timing, power, and area constraints are met throughout the design flow. This interdependence facilitates closed-loop optimization that enhances overall design quality.

Detailed

Integration of Logic and Physical Synthesis

In the realm of VLSI design, logic and physical synthesis are distinct yet closely interconnected steps in the design flow. Logic synthesis involves converting RTL (Register Transfer Level) descriptions into a gate-level netlist, while physical synthesis is concerned with the physical arrangement of these gates on a silicon chip to optimize for performance, area, and power consumption (PPA).

Key Interdependencies

- Impact of Logic Synthesis on Physical Synthesis: The structure of the logic synthesized directly informs how standard cells are arranged during physical synthesis. The logical structure dictates aspects such as timing and power optimizations.

- Feedback Loop: Timing and power improvements achieved during physical synthesis heavily rely on the characteristics of gates and their arrangement generated during the logic synthesis phase. This ensures both syntheses work together effectively, yielding better results in terms of PPA and manufacturability.

Closing the loop between these two processes is crucial in modern VLSI design, allowing for a cohesive approach that can tackle the complexities of today's electronic systems.

Youtube Videos

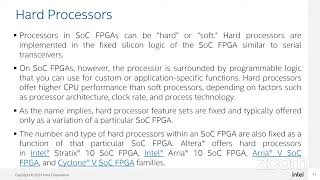

![Soft Embedded FPGA Fabrics: Top-down Physical Design and Applications [Invited]](https://img.youtube.com/vi/EnCksgkfq40/mqdefault.jpg)

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Interconnected Nature of Synthesis

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

While logic and physical synthesis are separate steps in the VLSI design process, they are closely interconnected.

Detailed Explanation

In VLSI design, there are two primary stages: logic synthesis and physical synthesis. Though these steps are distinct, they influence each other significantly. Logic synthesis transforms high-level design specifications into a gate-level representation, setting up the framework for physical synthesis, which deals with the actual placement and routing of these gates on the chip.

Examples & Analogies

Think of a blueprint for a house (logic synthesis) that outlines where each room will be and how they connect. The actual construction work (physical synthesis) then takes this blueprint to build the house. If the blueprint is poorly designed, the construction will be complicated, and conversely, if the construction crew doesn't follow the blueprint well, the house won't turn out right.

Influence of Logic on Physical Decisions

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The results from logic synthesis influence the decisions made during physical synthesis, and vice versa.

Detailed Explanation

The design created in logic synthesis directly impacts how the physical design is executed. For instance, the arrangement of the gates and their logical connections help determine how they will fit into standard cells and the overall layout during physical synthesis. If the logic design has complex connections, it would require careful placement to avoid long wiring, which would affect performance.

Examples & Analogies

Imagine preparing a jigsaw puzzle (logic synthesis) where the pieces are differently shaped. If you understand how the pieces fit together well (the logic), it makes it easier to figure out where each piece should go on the table (the chip layout). If the pieces are not aligned well in your understanding, the final puzzle will be difficult to complete.

Optimization Benefits through Integration

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

By integrating both synthesis processes, designers can achieve better results in terms of PPA and manufacturability.

Detailed Explanation

When logic and physical synthesis are integrated effectively, it leads to improvements in performance (speed), power usage, and area (size) of the chip, collectively known as PPA. This integration allows for a design process that continuously updates both logical designs and physical constraints, ensuring that both aspects work harmoniously to produce the best possible outcome. This feedback loop is crucial for optimizing the design for manufacturability and performance.

Examples & Analogies

Consider a chef preparing a dish. If the chef keeps tasting the dish while cooking (feedback loop), they can adjust the ingredients and cooking time to enhance the flavor and presentation. If they prepare it separately and only taste at the end, it might not come out as well as they would like. Similarly, continuous integration of logic and physical design leads to a better end product.

Closed-Loop Optimization

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Closed-loop optimization between logic and physical synthesis ensures that timing, power, and area constraints are met throughout the design flow.

Detailed Explanation

Closed-loop optimization refers to a design process where outputs from one stage inform adjustments in the other. For instance, if physical synthesis identifies areas where power consumption is too high, these insights can lead back to logic synthesis for adjustments that might reduce power usage, creating a more efficient design. This iterating process helps balance all essential metrics throughout the design workflow.

Examples & Analogies

Imagine a fitness regimen where you adjust your diet and exercise based on regular check-ins of your health and body metrics. If you notice you’re gaining too much weight, you might change your diet (analogous to logic synthesis) or increase your workouts (analogous to physical synthesis) to achieve your fitness goals. Here, each aspect informs the other, leading to improved overall health.

Key Concepts

-

Integration of Logic and Physical Synthesis: The interdependency between logic synthesis and physical synthesis enhances design performance and manufacturability.

-

Closed-Loop Optimization: Utilizes feedback from one synthesis phase to adjust and improve the other.

Examples & Applications

Example 1: If a logic synthesis identifies a timing-critical path, the physical synthesis must account for that route to minimize delay.

Example 2: Reducing power during physical synthesis can require modifications in logic synthesis to align functionalities with the new power constraints.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

When logic meets placement, power optimally won't be wasted.

Stories

Imagine two friends, Logic and Physical, who work together to plan a perfect party layout that optimizes space and enjoyment for all guests.

Memory Tools

PPA - Think of 'Perfect Party Arrangement' to remember Power, Performance, and Area.

Acronyms

LPS - Logic's Placement Synergy

Highlighting the collaboration of logic and placement for better designs.

Flash Cards

Glossary

- Logic Synthesis

The process of converting high-level RTL code into a gate-level representation optimized for performance, power, and area.

- Physical Synthesis

The optimization of the physical placement and routing of standard cells on a chip to meet timing, power, and area requirements.

- PPA

Power, Performance, and Area; key metrics in VLSI design optimization.

- ClosedLoop Optimization

A process where feedback from one stage (logic or physical synthesis) informs and improves the other stage.

Reference links

Supplementary resources to enhance your learning experience.